BM 1609929Y07 10-10:BM 1609929Y07 10-10 1/18/11 10:06 AM Page 12

SANDING ACCESSORIES ASSEMBLY |

|

| |

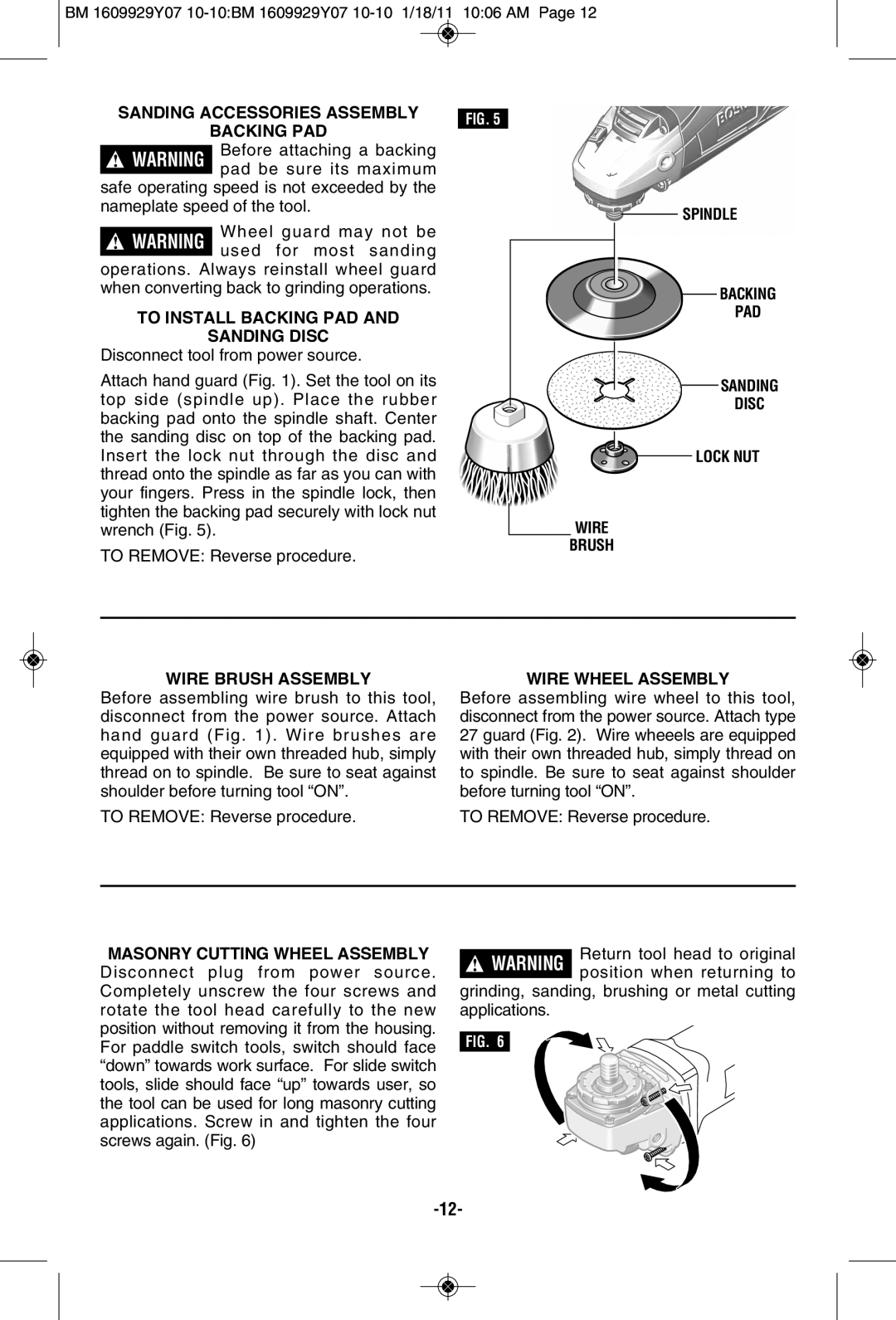

FIG. 5 |

| ||

BACKING PAD |

|

| |

| Before attaching a backing |

|

|

! WARNING |

|

| |

pad be sure its maximum |

|

| |

|

|

| |

safe operating speed is not exceeded by the |

|

| |

nameplate speed of the tool. |

|

| |

| Wheel guard may not be |

|

|

! WARNING |

|

| |

used for most sanding |

|

| |

|

|

| |

operations. Always reinstall wheel guard |

|

| |

when converting back to grinding operations. |

|

| |

TO INSTALL BACKING PAD AND |

|

| |

SANDING DISC |

|

| |

Disconnect tool from power source. |

|

| |

Attach hand guard (Fig. 1). Set the tool on its |

|

| |

top side (spindle up). Place the rubber |

|

| |

backing pad onto the spindle shaft. Center |

|

| |

the sanding disc on top of the backing pad. |

|

| |

Insert the lock nut through the disc and |

|

| |

thread onto the spindle as far as you can with |

|

| |

|

| ||

your fingers. Press in the spindle lock, then |

|

| |

|

| ||

tighten the backing pad securely with lock nut |

|

| |

wrench (Fig. 5). |

|

| |

TO REMOVE: Reverse procedure. |

|

| |

SPINDLE

BACKING |

PAD |

SANDING

DISC

LOCK NUT

WIRE

BRUSH

WIRE BRUSH ASSEMBLY

Before assembling wire brush to this tool, disconnect from the power source. Attach hand guard (Fig. 1). Wire brushes are equipped with their own threaded hub, simply thread on to spindle. Be sure to seat against shoulder before turning tool “ON”.

TO REMOVE: Reverse procedure.

WIRE WHEEL ASSEMBLY

Before assembling wire wheel to this tool, disconnect from the power source. Attach type 27 guard (Fig. 2). Wire wheeels are equipped with their own threaded hub, simply thread on to spindle. Be sure to seat against shoulder before turning tool “ON”.

TO REMOVE: Reverse procedure.

MASONRY CUTTING WHEEL ASSEMBLY Disconnect plug from power source. Completely unscrew the four screws and rotate the tool head carefully to the new position without removing it from the housing. For paddle switch tools, switch should face “down” towards work surface. For slide switch tools, slide should face “up” towards user, so the tool can be used for long masonry cutting applications. Screw in and tighten the four screws again. (Fig. 6)

!WARNING Return tool head to original position when returning to

grinding, sanding, brushing or metal cutting applications.

FIG. 6