![]() BM 2610034439

BM 2610034439

Excessive or sudden pres- ! WARNING sure on the wheel will slow

grinding action and put dangerous stresses on the wheel.

When grinding with a new wheel be certain to grind while pulling tool backwards until wheel becomes rounded on its edge. New wheels have sharp corners which tend to “bite” or cut into workpiece when pushing forward.

CUTTING METAL

Using the optional type 1A wheel guard, it is possible to perform limited cutting on small stock such as metal tubes, piping or rebar. When cutting, work with moderate feed, adapted to the material being cut. Do not exert side pressure onto the cutting disc, tilt or oscillate the tool. When cutting profiles and square bar, it is best to start at the smallest cross section.

Always follow precautions for kickback.

Do not apply side pressure to cutting wheel to reduce wheel speed.

The tool should always be used so that sparks are directed away from user.

CUTTING MASONRy

Operate the tool only with dust extraction and additionally wear a dust protection mask. The vacuum used for this application must be approved for the extraction of masonry dust. Bosch sells suitable vacuum cleaners.

When cutting masonry ! WARNING always use dust extraction

with foot plate. The tool may be used only for dry cutting. When cutting masonry use a dry diamond wheel.

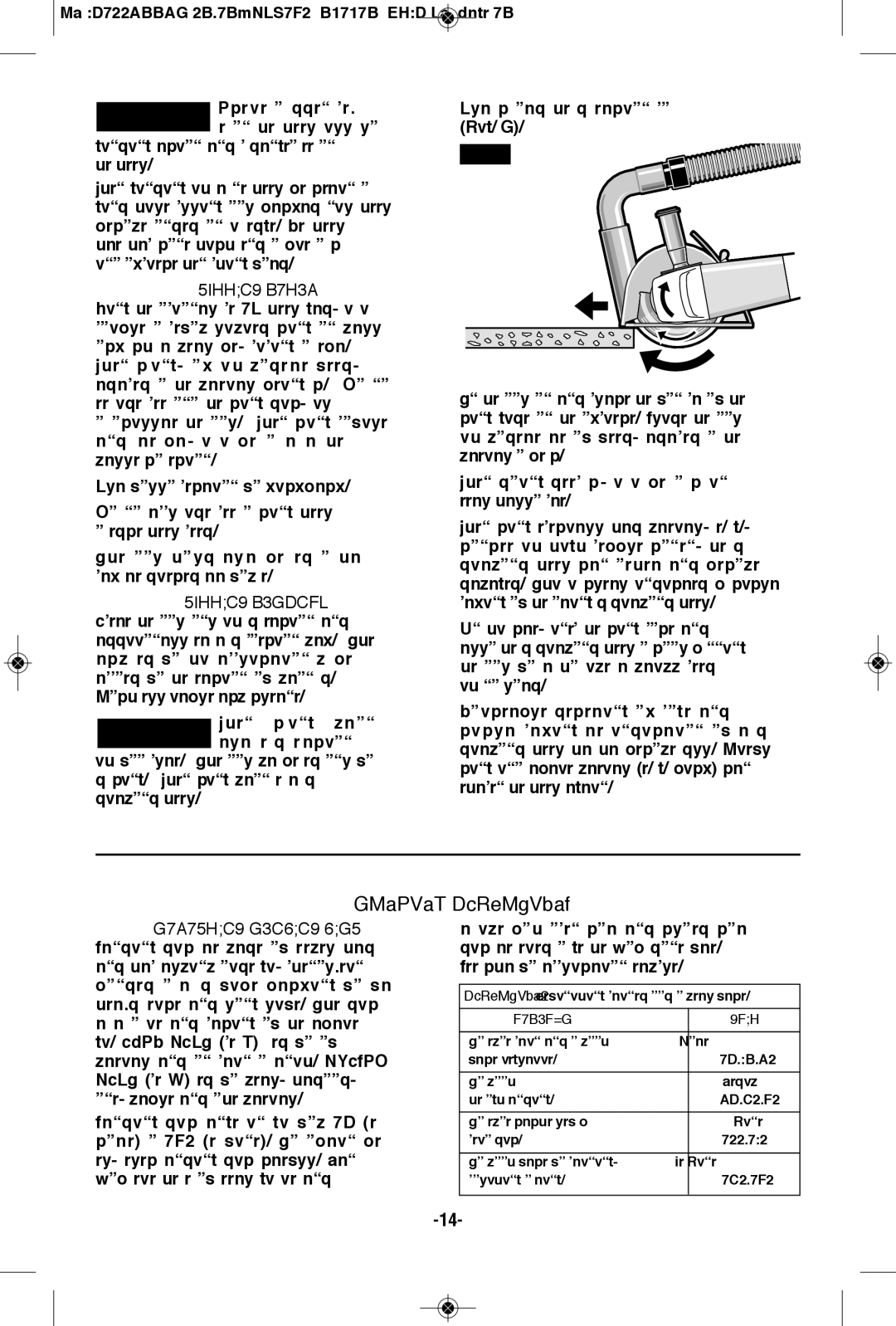

Always cut towards the dust extraction port (Fig. 9).

FIG. 9

Turn the tool on and place the front part of the cutting guide on the workpiece. Slide the tool with moderate rate of feed, adapted to the material to be cut.

When doing deep cuts, it is best to cut in several shallow passes.

When cutting especially hard material, e. g., concrete with high pebble content, the dry diamond wheel can overheat and become damaged. This is clearly indicated by circular sparking of the rotating dry diamond wheel.

In this case, interrupt the cutting process and allow the dry diamond wheel to cool by running the tool for a short time at maximum speed with no load.

Noticeable decreasing work progress and circular sparking are indications of a dry diamond wheel that has become dull. Briefly cutting into abrasive materials (e. g. brick) can resharpen the wheel again.

Sanding Operations

SELECTING SANDING DISC

Sanding discs are made of extremely hard and sharp aluminum oxide grits,

Sanding discs range in grit from 16 (very coarse) to 180 (very fine). To obtain best results, select sanding discs carefully. Many jobs require the use of several grit sizes and

at times both “open coat and closed coat” discs are required to get the job done faster. See chart for application examples.

Operation: Refinishing painted wood or metal surfaces.

REMARKS | GRIT |

|

|

To remove paint and to smooth | Coarse |

surface irregularities. | |

|

|

To smooth | Medium |

the rough sanding. | |

|

|

To remove scratches left by | Fine |

previous discs. | |

|

|

To smooth surfaces for painting, | Very Fine |

polishing or waxing. | |

|

|