3 OPERATING INSTRUCTIONS

Before Use

Auxiliary Handle (see Fig. ![]() )

)

Operate the machine only with the auxiliary han- dle 11.

By rotating the auxiliary handle 11 to a comfortable po- sition, a

Loosen the auxiliary handle 11 by turning counter clockwise and swing it to the desired position. Then retighten the auxiliary handle 11 by turning in the clockwise direction.

Selection of Tools

For hammer drilling and chiseling (only with the acces- sory MV 200),

For drilling in steel or wood, driving screws and cutting threads, tools without

Take care when changing tools that the dust pro- tection cap 2 is not damaged.

The

Inserting a SDS-Plus Tool (see Fig.  )

)

Clean the tool before inserting and lightly grease the insertion end.

Insert the tool with a twisting motion into the tool hold- er 1 until it locks.

The tool locks itself. Check the locking by pulling on the tool.

Removing SDS-Plus Tools (see Fig.  )

)

Pull the locking sleeve 3 to the rear (a), hold it in this position and remove the tool from the tool holder (b).

Setting the Drilling Depth (see Fig.  )

)

With the depth stop 10, the maximum drilling depth t can be set.

Press the button 9 of the auxiliary handle and insert the depth stop into the auxiliary handle 11 so that the grooved side of the depth stop points downward.

Insert the

Dust Extraction with the Vacuuming Attachment (Accessory)

For vacuuming dust, a dust extraction attachment (ac- cessory) is required. While drilling, the dust extraction attachment springs back so that the vacuuming head is always held against the drilled surface.

Press the button 9 of the auxiliary handle and remove the depth stop 10. Press the button 9 again and insert the dust extraction attachment from the front into the auxiliary handle 11 (see Fig. ![]() ).

).

The maximum drilling depth t can also be set with the dust extraction attachment mounted. For this pur- pose, place the machine without switching on firmly against the area to be drilled so that the drill rests on the surface. Read the value from the scale of the dust extraction attachment and add the desired drilling depth t to this value.

Loosen the knurled screw on the depth stop of the dust extraction attachment and slide the depth stop to the calculated value. Then retighten the knurled screw of the depth stop.

Connect a vacuum hose (19 mm Ø, accessory) to the opening of the dust extraction attachment.

The vacuum cleaner (e.g., GAS ...) must be suitable for the material to be worked.

When vacuuming dry dust that is especially detrimen- tal to health or carcinogenic, use a special vacuum cleaner.

Putting into Operation

Always use the correct supply voltage!

The voltage of the power source must agree with the value given on the nameplate of the machine. Machines designated for 230 V can also be operated with 220 V.

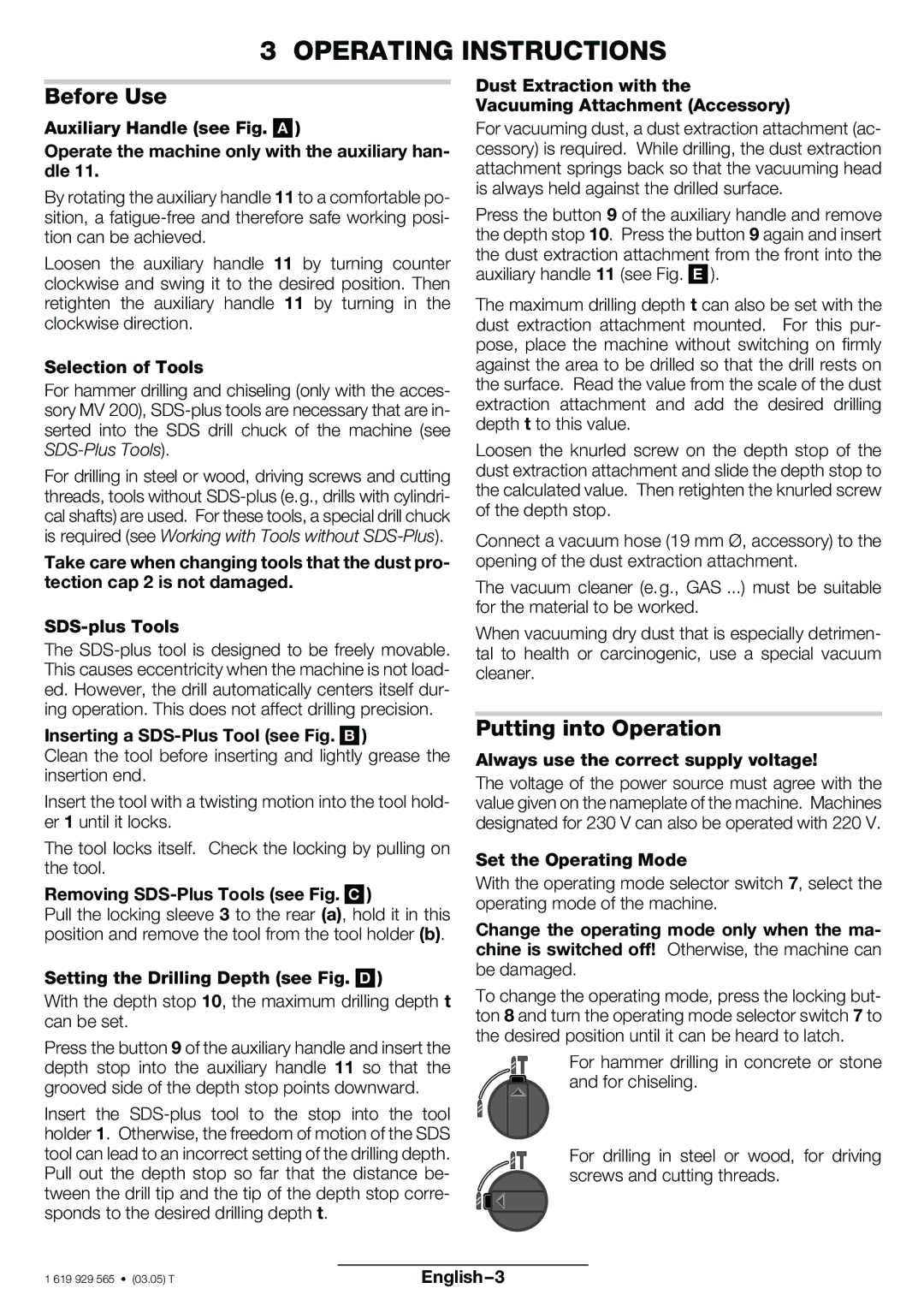

Set the Operating Mode

With the operating mode selector switch 7, select the operating mode of the machine.

Change the operating mode only when the ma- chine is switched off! Otherwise, the machine can be damaged.

To change the operating mode, press the locking but- ton 8 and turn the operating mode selector switch 7 to the desired position until it can be heard to latch.

For hammer drilling in concrete or stone and for chiseling.

For drilling in steel or wood, for driving screws and cutting threads.

1 619 929 565 • (03.05) T |