BM 1619929572

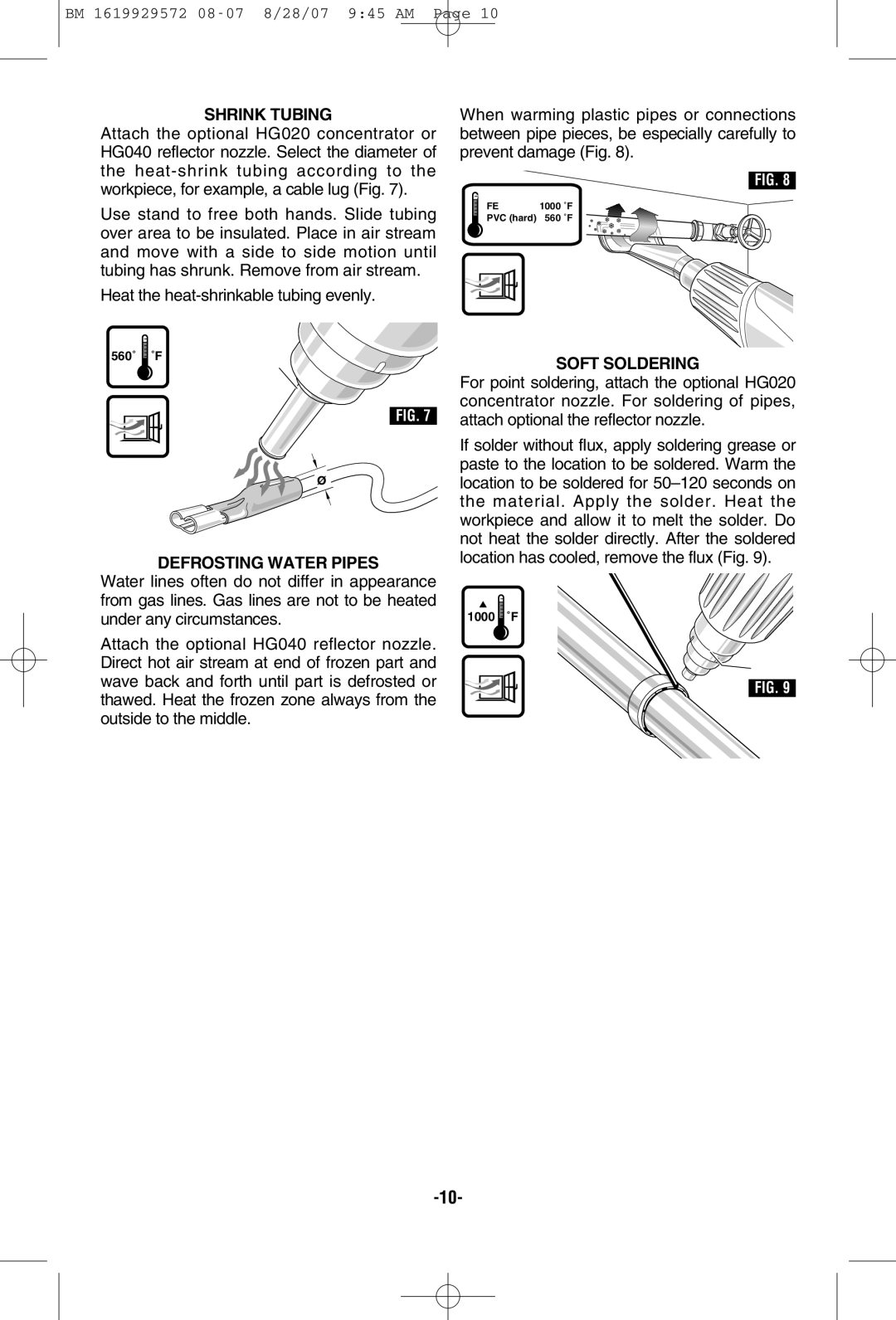

SHRINK TUBING

Attach the optional HG020 concentrator or HG040 reflector nozzle. Select the diameter of the

Use stand to free both hands. Slide tubing over area to be insulated. Place in air stream and move with a side to side motion until tubing has shrunk. Remove from air stream.

Heat the

When warming plastic pipes or connections between pipe pieces, be especially carefully to prevent damage (Fig. 8).

FIG. 8

| FE | 1000 | ˚F | |

| PVC (hard) | 560 | ˚F | |

|

|

|

|

|

|

|

|

|

|

560˚ ![]() ˚F

˚F

FIG. 7

DEFROSTING WATER PIPES

Water lines often do not differ in appearance from gas lines. Gas lines are not to be heated under any circumstances.

Attach the optional HG040 reflector nozzle. Direct hot air stream at end of frozen part and wave back and forth until part is defrosted or thawed. Heat the frozen zone always from the outside to the middle.

SOFT SOLDERING

For point soldering, attach the optional HG020 concentrator nozzle. For soldering of pipes, attach optional the reflector nozzle.

If solder without flux, apply soldering grease or paste to the location to be soldered. Warm the location to be soldered for

1000 ![]() ˚F

˚F

FIG. 9