BM 1619929572

SETTING THE AIR FLOW

The air flow can be regulated with the air flow button (Fig. 1).

Minimum air flow (approx.

![]()

![]()

![]() Maximum air flow (approx. 17.6 CFM)

Maximum air flow (approx. 17.6 CFM)

The CFM at each of the 10 airflow settings depends on the temperature setting. For example, at the lowest temperature (120 degrees) the lowest airflow setting delivers 3.6 cfm, whereas at the highest temperature (1200 degrees) the lowest airflow setting delivers 8.8 cfm

The air flow can be increased by pressing the “+” side of the air flow button or decreased by pushing the

Decrease the air flow when, for example: The surroundings of the workpiece should not be heated more than necessary. A light workpiece could be blown away by the air stream.

PROGRAMMED OPERATION

In programmed operation, air flow and temperature settings can be stored in four programs. In each program, any air flow and temperature combination are possible.

Also in programmed operation, air flow and temperature can be changed at any time. If the changes are not stored through reprogramming, they are lost when switching the unit off or when changing to another program.

To use one of the ![]() ,

, ![]() ,

, ![]() or

or ![]() ) as shown in the display (Fig. 2).

) as shown in the display (Fig. 2).

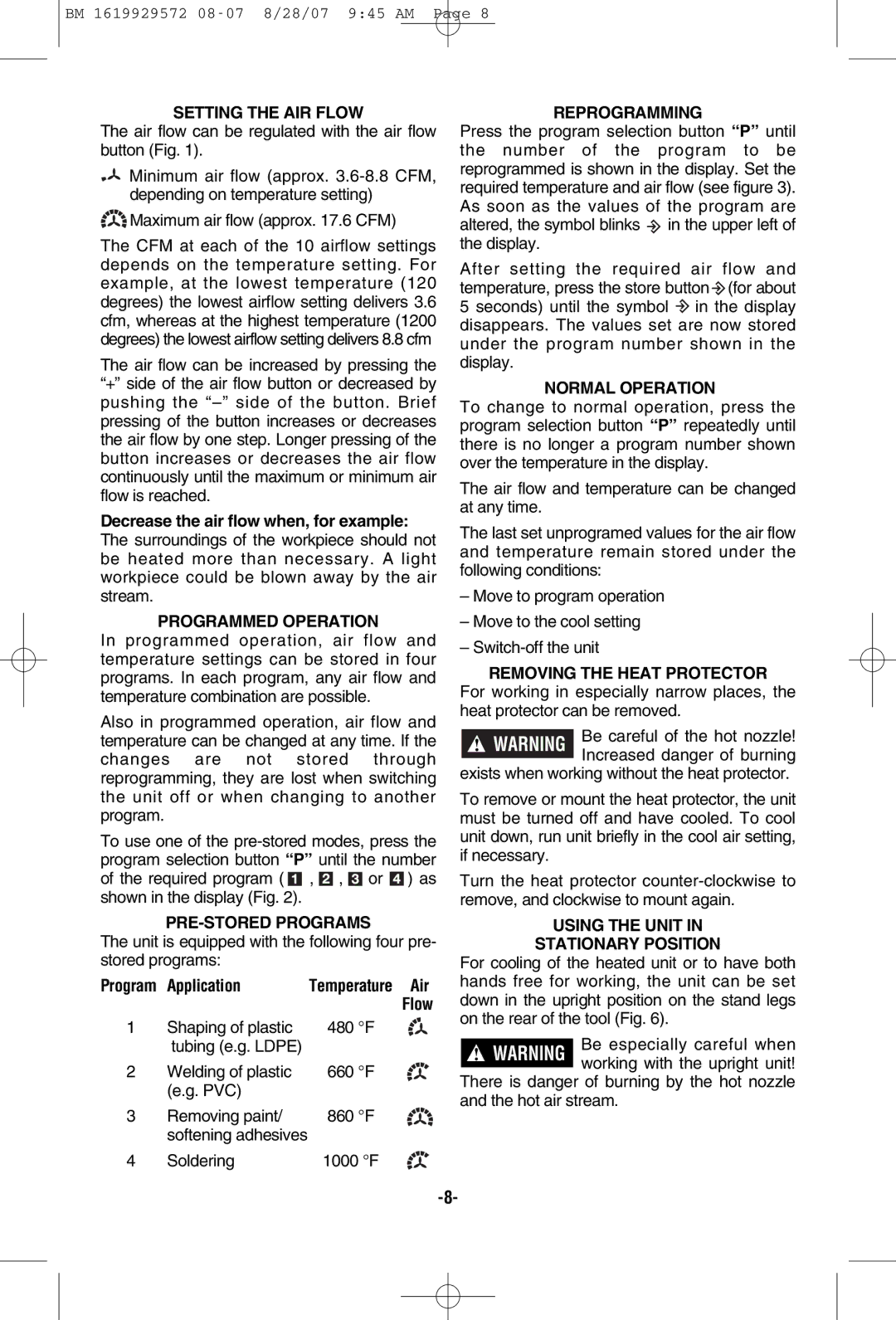

PRE-STORED PROGRAMS

The unit is equipped with the following four pre- stored programs:

Program | Application | Temperature Air |

|

| Flow |

1 | Shaping of plastic | 480 °F |

| tubing (e.g. LDPE) |

|

2 | Welding of plastic | 660 °F |

| (e.g. PVC) |

|

3 | Removing paint/ | 860 °F |

| softening adhesives |

|

4 | Soldering | 1000 °F |

REPROGRAMMING

Press the program selection button “P” until the number of the program to be reprogrammed is shown in the display. Set the required temperature and air flow (see figure 3). As soon as the values of the program are altered, the symbol blinks ![]() in the upper left of the display.

in the upper left of the display.

After setting the required air flow and temperature, press the store button ![]() (for about 5 seconds) until the symbol

(for about 5 seconds) until the symbol ![]() in the display disappears. The values set are now stored under the program number shown in the display.

in the display disappears. The values set are now stored under the program number shown in the display.

NORMAL OPERATION

To change to normal operation, press the program selection button “P” repeatedly until there is no longer a program number shown over the temperature in the display.

The air flow and temperature can be changed at any time.

The last set unprogramed values for the air flow and temperature remain stored under the following conditions:

–Move to program operation

–Move to the cool setting

–

REMOVING THE HEAT PROTECTOR

For working in especially narrow places, the heat protector can be removed.

!WARNING Be careful of the hot nozzle! Increased danger of burning

exists when working without the heat protector.

To remove or mount the heat protector, the unit must be turned off and have cooled. To cool unit down, run unit briefly in the cool air setting, if necessary.

Turn the heat protector

USING THE UNIT IN

STATIONARY POSITION

For cooling of the heated unit or to have both hands free for working, the unit can be set down in the upright position on the stand legs on the rear of the tool (Fig. 6).

!WARNING Be especially careful when working with the upright unit!

There is danger of burning by the hot nozzle and the hot air stream.