R0S20VS, ROS10 specifications

Bosch Power Tools has built a formidable reputation for producing high-quality tools that cater to both professionals and DIY enthusiasts. Among their stellar lineup are the ROS10 and ROS20VS random orbit sanders, which showcase the company’s commitment to innovation, durability, and user comfort.The Bosch ROS10 is designed for smooth and efficient sanding tasks. One of its notable features is the Microfilter System, which helps trap dust particles as small as half a micron. This ensures a cleaner workspace and contributes to better visibility while sanding. Moreover, the ROS10 offers a 2.5-amp motor that provides a robust performance with a no-load speed of up to 12,000 orbits per minute. This makes it ideal for various applications, from removing old paint to preparing surfaces for finishing.

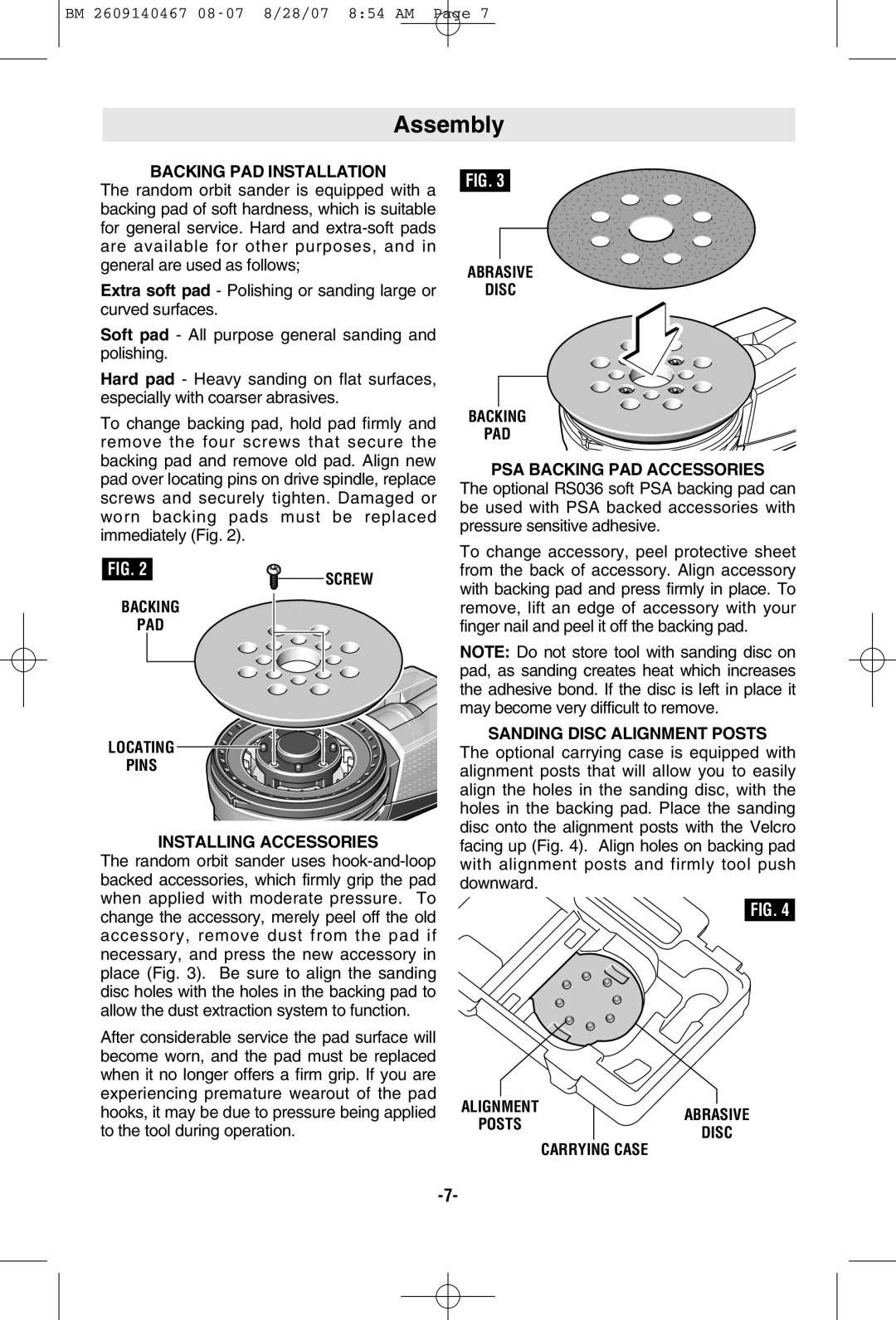

An ergonomic design is a key characteristic of the ROS10, featuring a soft-grip top and body that enhance comfort during extended use. The tool’s lightweight build further minimizes user fatigue, allowing for longer sanding sessions with reduced strain. The hook-and-loop attachment system for sandpaper makes changing sandpaper discs swift and hassle-free, promoting increased productivity.

On the other hand, the Bosch ROS20VS brings versatile features that make it suitable for both detailed tasks and broader sanding jobs. It boasts an integrated dust collection system that actively collects dust through a built-in vacuum port, ensuring a clean and efficient work environment. Equipped with a variable speed control, the ROS20VS allows users to customize the speed depending on the material and the type of project, making it adaptable for a wide range of tasks.

With its 2.5-amp motor and premium construction, the ROS20VS also delivers exceptional power and durability. This sander includes an ergonomic design that combines comfort with control, featuring a soft-grip handle and well-balanced structure. Additionally, the user-friendly design of the dust canister makes it easy to empty and clean after use.

In summary, both the Bosch ROS10 and ROS20VS random orbit sanders are engineered to offer remarkable performance, effective dust management, and superb handling. Their advancing technologies and user-centric features make them indispensable tools in any woodworking or remodeling project. Whether you’re a seasoned professional or a dedicated DIYer, these sanders promise to deliver outstanding results every time. Make a choice between these two tools based on your specific needs, and elevate your sanding experience to new heights.