RZ 2610917368

Assembly

Disconnect the plug from the power source before making any assembly, adjustments or

changing accessories. Such preventive safety measures reduce the risk of starting the tool accidentally. Make certain that the collet nut is securely tightened before turning the tool on.

REMOVING AND INSTALLING THE

DEPTH GUIDE ASSEMBLY

The depth guide assembly consists of the depth guide, locking screw and bracket.

In order to remove the depth guide from the tool, release the locking lever and pull the entire assembly straight off of the tool. To reattach the assembly, fully replace the guide

onto the tool collar and lock the clamp lever (Fig. 1).

REMOVING AND INSTALLING THE

DUST HOOD ASSEMBLY

(Not included, available as accessory)

The dust hood is sized to accept 35mm vacuum hoses.

The dust hood assembly consists of the dust hood, locking knob and bracket.

In order to remove the dust hood assembly from the tool, release the locking lever and pull the entire assembly straight off of the tool. To reattach the assembly, fully replace the guide onto the tool collar and lock the clamp lever (Fig. 1).

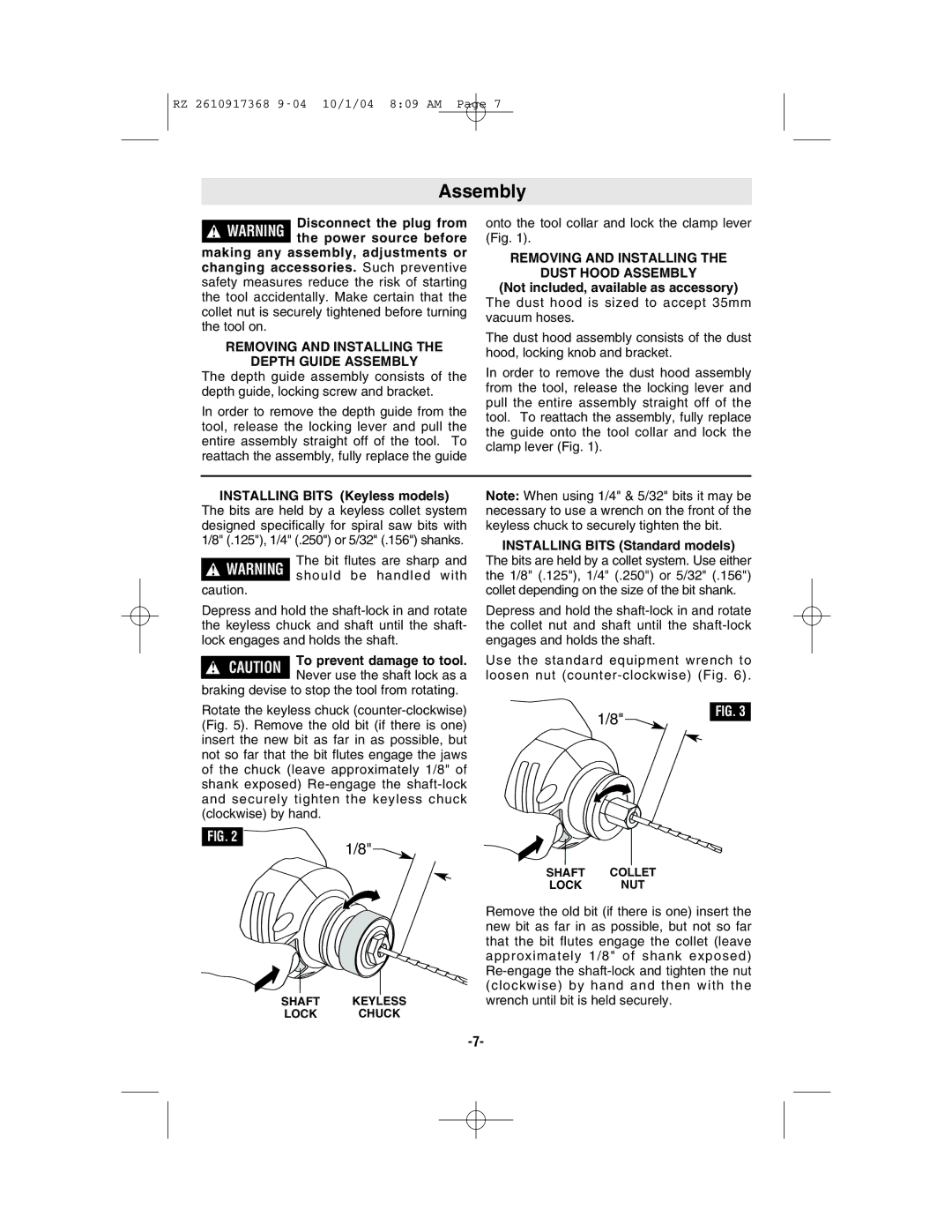

INSTALLING BITS (Keyless models)

The bits are held by a keyless collet system designed specifically for spiral saw bits with 1/8" (.125"), 1/4" (.250") or 5/32" (.156") shanks.

The bit flutes are sharp and ! WARNING should be handled with

caution.

Depress and hold the

To prevent damage to tool. Never use the shaft lock as a

braking devise to stop the tool from rotating.

Rotate the keyless chuck

FIG. 2

1/8"

SHAFT KEYLESS

LOCK CHUCK

Note: When using 1/4" & 5/32" bits it may be necessary to use a wrench on the front of the keyless chuck to securely tighten the bit.

INSTALLING BITS (Standard models)

The bits are held by a collet system. Use either the 1/8" (.125"), 1/4" (.250") or 5/32" (.156") collet depending on the size of the bit shank.

Depress and hold the

Use the standard equipment wrench to loosen nut

1/8" |

|

| FIG. 3 |

|

|

|

SHAFT COLLET

LOCK NUT

Remove the old bit (if there is one) insert the new bit as far in as possible, but not so far that the bit flutes engage the collet (leave approximately 1/8" of shank exposed)