Metal Drilling

BOSCH Professional Drilling

TITANIUM |

| BLACK OXIDE |

|

|

|

COBALT

Titanium coating

Applications: Designed for repetitive

•Dramatically reduces heat and friction between bit and workpiece, making bits last up to 6X longer than standard HSS bits.

•Allows faster drilling speeds.

•Surface hardness in excess of 80 HRC to penetrate tough materials, including common stainless steels.

Speed Helix

•Faster penetration, easier drilling, reduced heat.

•Extended drill bit life, extended cordless battery life.

135° split point

•Starts drilling on contact.

•No walking or skating.

•No center punch required.

Black oxide heat treatment

Applications: Designed for general purpose

1/2" reduced shank (Silver & Deming).

•Reduces friction between bit and workpiece.

•Extends drill bit life.

Speed Helix

•Faster penetration, easier drilling, reduced heat.

•Extended drill bit life, extended cordless battery life.

135° split point

•Starts drilling on contact.

•No walking or skating.

•No center punch required.

Cobalt

Applications: Designed for

•Cobalt formulation provides overall bit hardness of

•Able to withstand very high temperature drilling applications for extended periods of time.

•Under high drilling temperatures, bits stay sharper longer than standard HSS.

•Thicker web increases rigidity in hard materials.

135° split point

•Starts drilling on contact.

•No walking or skating.

•No center punch required.

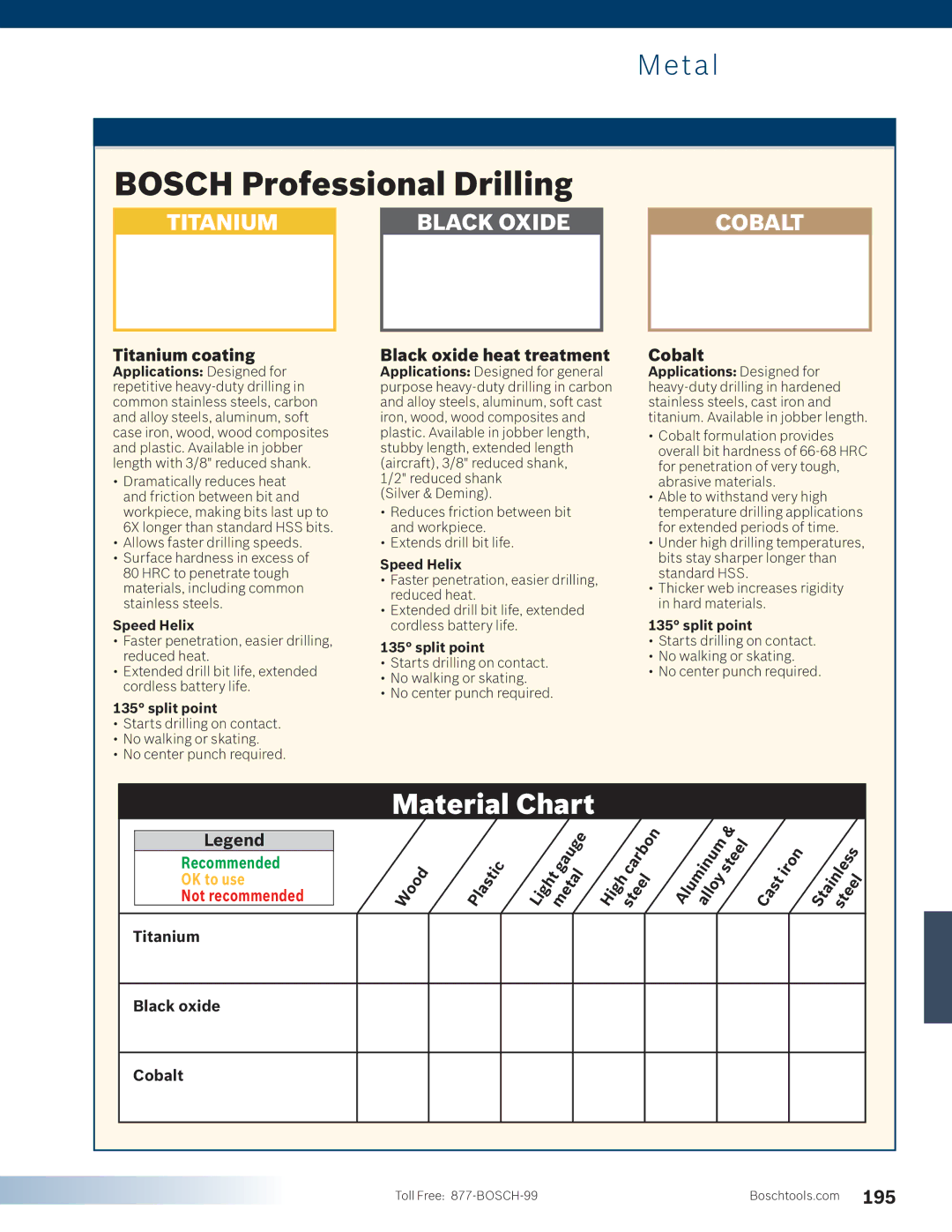

Material Chart

Legend |

|

|

| gauge |

| carbon | Aluminum | & |

|

|

|

|

|

|

|

| steel |

| iron | Stainlesssteel |

| ||||

✔ Recommended | Wood | Plastic |

|

|

|

| ||||||

✔ OK to use |

|

|

|

| ||||||||

Light | metal | High | steel |

| Cast |

|

| |||||

✔ Not recommended |

|

|

| |||||||||

|

|

|

| |||||||||

| alloy |

|

|

| ||||||||

Titanium | ✔ | ✔ | ✔ |

| ✔ |

| ✔ | ✔ |

| ✔ |

| |

|

|

|

|

| ||||||||

Black oxide | ✔ | ✔ | ✔ |

| ✔ |

| ✔ | ✔ |

| ✔ |

| |

|

|

|

|

| ||||||||

Cobalt | ✔ | ✔ | ✔ |

| ✔ |

| ✔ | ✔ |

| ✔ |

| |

|

|

|

|

| ||||||||

| Toll Free: |

|

|

|

|

| Boschtools.com | 195 | ||||