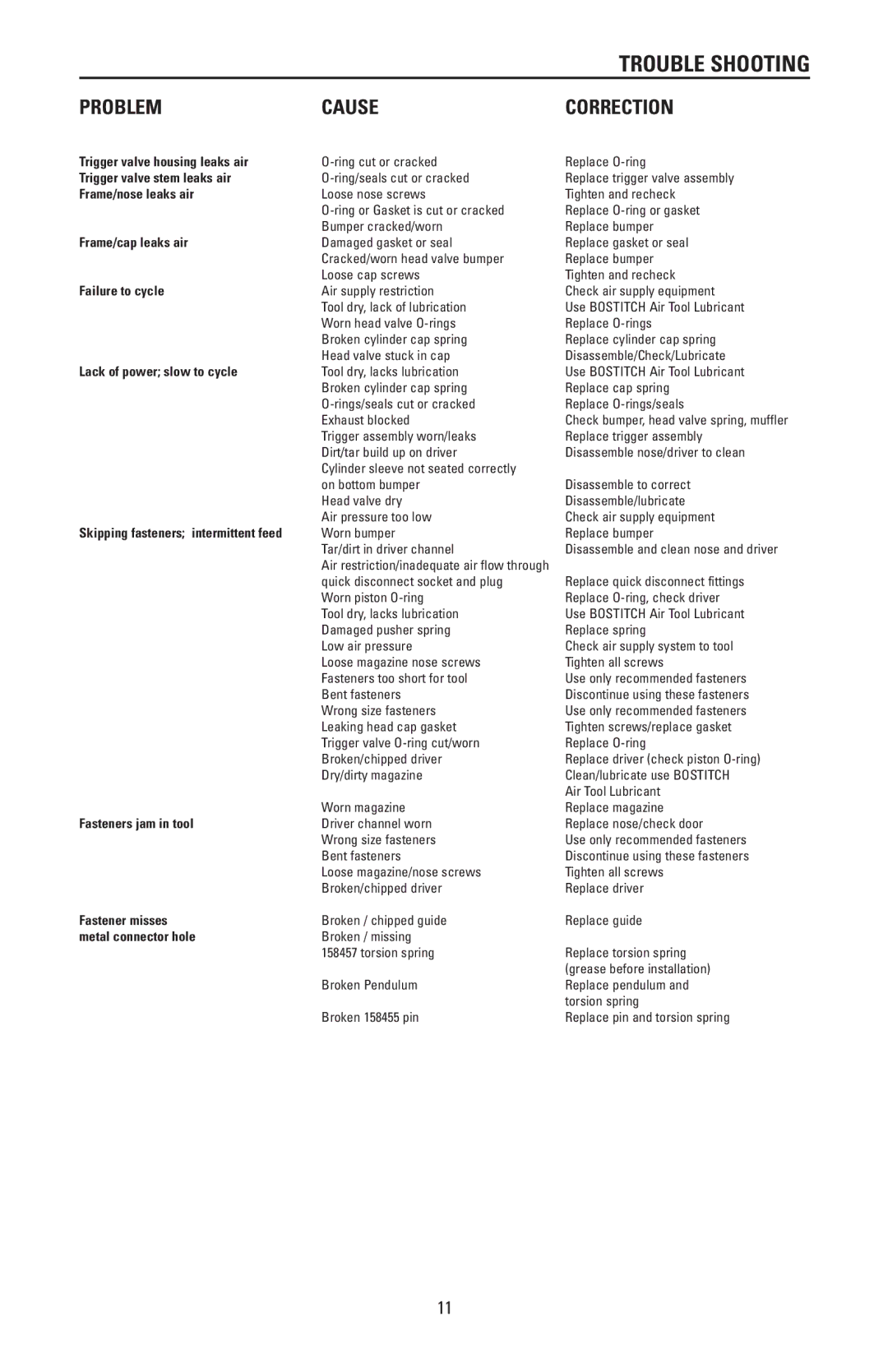

TROUBLE SHOOTING

PROBLEM | CAUSE | CORRECTION |

Trigger valve housing leaks air Trigger valve stem leaks air Frame/nose leaks air

Frame/cap leaks air

Failure to cycle

Lack of power; slow to cycle

Skipping fasteners; intermittent feed

Fasteners jam in tool

Fastener misses metal connector hole

Air supply restriction

Tool dry, lack of lubrication Worn head valve

Trigger assembly worn/leaks Dirt/tar build up on driver Cylinder sleeve not seated correctly on bottom bumper

Head valve dry

Air pressure too low Worn bumper

Tar/dirt in driver channel

Air restriction/inadequate air flow through quick disconnect socket and plug

Worn piston

Tool dry, lacks lubrication Damaged pusher spring Low air pressure

Loose magazine nose screws Fasteners too short for tool Bent fasteners

Wrong size fasteners Leaking head cap gasket Trigger valve

Worn magazine

Driver channel worn

Wrong size fasteners

Bent fasteners

Loose magazine/nose screws

Broken/chipped driver

Broken / chipped guide Broken / missing 158457 torsion spring

Broken Pendulum

Broken 158455 pin

Replace

Replace trigger valve assembly Tighten and recheck Replace

Replace gasket or seal Replace bumper Tighten and recheck Check air supply equipment

Use BOSTITCH Air Tool Lubricant Replace

Replace cylinder cap spring Disassemble/Check/Lubricate Use BOSTITCH Air Tool Lubricant Replace cap spring

Replace

Check bumper, head valve spring, muffler Replace trigger assembly Disassemble nose/driver to clean

Disassemble to correct Disassemble/lubricate Check air supply equipment Replace bumper

Disassemble and clean nose and driver

Replace quick disconnect fittings Replace

Check air supply system to tool Tighten all screws

Use only recommended fasteners Discontinue using these fasteners Use only recommended fasteners Tighten screws/replace gasket Replace

Replace driver (check piston

Air Tool Lubricant Replace magazine Replace nose/check door

Use only recommended fasteners Discontinue using these fasteners Tighten all screws

Replace driver

Replace guide

Replace torsion spring (grease before installation) Replace pendulum and torsion spring

Replace pin and torsion spring

11