X

6.5 inch (16.5 cm) |

|

|

|

|

| ||

Min. Diameter Hole in Wall | 11 1/2 |

|

| ||||

|

|

|

|

| |||

|

|

|

|

|

|

|

|

| 11 9/16 |

|

|

|

|

| |

|

|

|

| 7 3/16” |

| ||

Y |

| Boot Extension | |||||

|

|

|

| ||||

| H |

| SIDE WATER OUTLET |

| A |

| B |

C |

|

E & F | DRAIN VALVE |

1/2” GAS | SIDE WATER INLET |

| |

CONNECTION |

|

D | G |

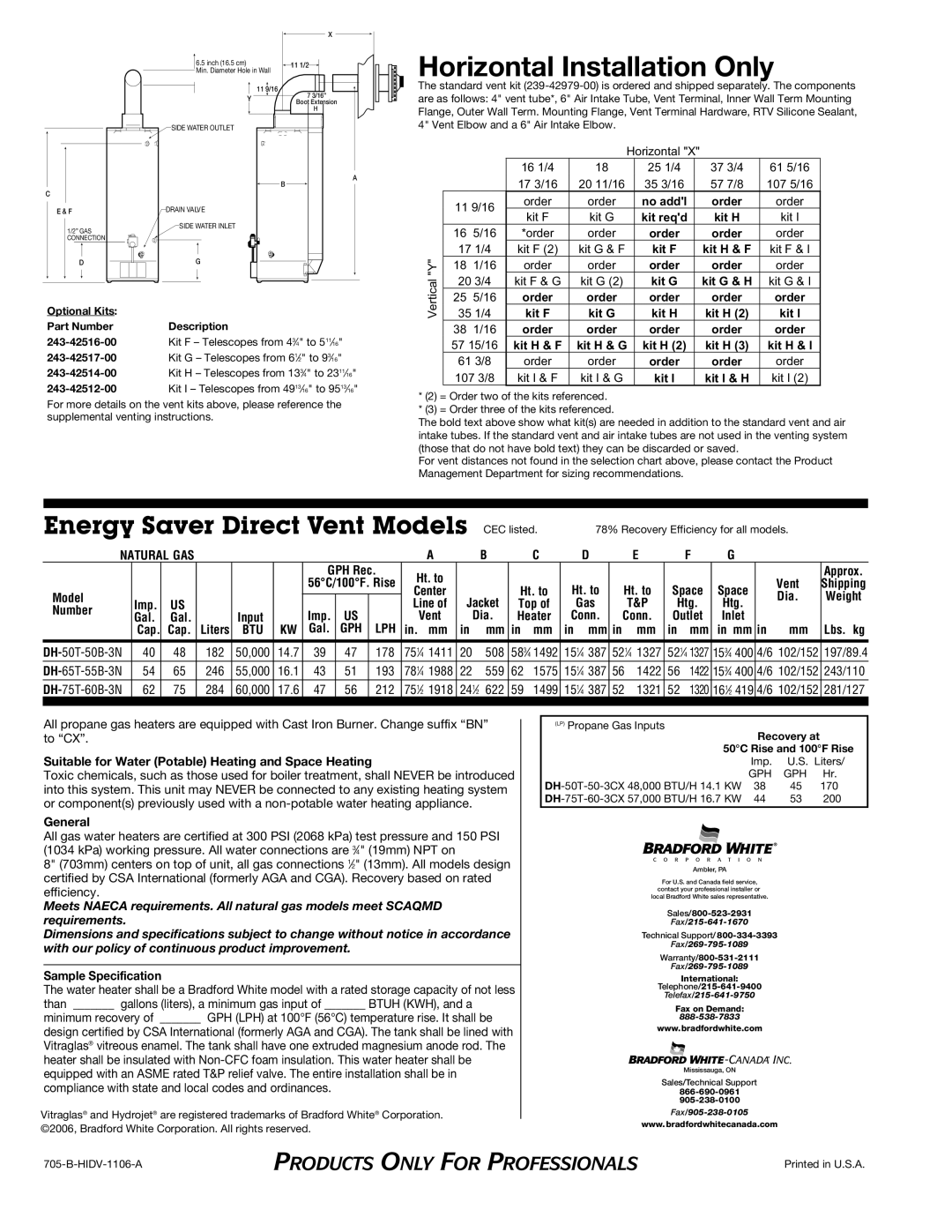

Optional Kits: |

|

Part Number | Description |

Kit F – Telescopes from 43⁄4" to 511⁄16" | |

Kit G – Telescopes from 61⁄2" to 93⁄16" | |

Kit H – Telescopes from 133⁄4" to 2311⁄16" | |

| Kit I – Telescopes from 4913⁄16" to 9513⁄16" |

For more details on the vent kits above, please reference the supplemental venting instructions.

Horizontal Installation Only

The standard vent kit

|

|

|

| Horizontal "X" |

|

| ||

|

|

| 16 1/4 | 18 | 25 1/4 |

| 37 3/4 | 61 5/16 |

|

|

| 17 3/16 | 20 11/16 | 35 3/16 |

| 57 7/8 | 107 5/16 |

| 11 9/16 | order | order | no add'l |

| order | order | |

| kit F | kit G | kit req'd |

| kit H | kit I | ||

|

|

|

| |||||

| 16 | 5/16 | *order | order | order |

| order | order |

"Y" | 17 1/4 | kit F (2) | kit G & F | kit F |

| kit H & F | kit F & I | |

18 | 1/16 | order | order | order |

| order | order | |

20 3/4 | kit F & G | kit G (2) | kit G |

| kit G & H | kit G & I | ||

Vertical |

| |||||||

35 1/4 | kit F | kit G | kit H |

| kit H (2) | kit I | ||

| 25 | 5/16 | order | order | order |

| order | order |

|

|

|

|

|

|

|

|

|

| 38 | 1/16 | order | order | order |

| order | order |

| 57 15/16 | kit H & F | kit H & G | kit H (2) |

| kit H (3) | kit H & I | |

| 61 3/8 | order | order | order |

| order | order | |

| 107 3/8 | kit I & F | kit I & G | kit I |

| kit I & H | kit I (2) | |

*(2) = Order two of the kits referenced.

*(3) = Order three of the kits referenced.

The bold text above show what kit(s) are needed in addition to the standard vent and air intake tubes. If the standard vent and air intake tubes are not used in the venting system (those that do not have bold text) they can be discarded or saved.

For vent distances not found in the selection chart above, please contact the Product Management Department for sizing recommendations.

Energy Saver Direct Vent Models CEC listed. |

| 78% Recovery Efficiency for all models. |

| ||||||||||||||||||||||||

| NATURAL GAS |

|

|

|

|

|

|

|

| A |

| B |

| C | D |

| E |

| F | G |

|

| |||||

|

|

|

|

|

|

|

| GPH Rec. | Ht. to |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Approx. | |||

|

|

|

|

|

|

|

| 56°C/100°F. Rise |

|

|

|

| Ht. to | Ht. to | Space | Space |

| Vent | Shipping | ||||||||

|

|

|

|

|

|

|

| Center |

|

| Ht. to |

| |||||||||||||||

Model |

|

|

|

|

|

|

|

|

|

| Jacket |

| Dia. | Weight | |||||||||||||

| Imp. | US |

|

|

|

|

|

|

| Line of | Top of | Gas |

| T&P | Htg. | Htg. |

| ||||||||||

Number |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||

| Gal. | Gal. |

| Input |

|

| Imp. | US |

| Vent | Dia. | Heater | Conn. | Conn. | Outlet | Inlet |

|

|

| ||||||||

|

|

|

|

|

|

|

|

| |||||||||||||||||||

|

| Cap. | Cap. | Liters | BTU | KW | Gal. | GPH | LPH | in. | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in mm | in | mm | Lbs. kg | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

40 | 48 | 182 | 50,000 | 14.7 |

| 39 | 47 | 178 | 751⁄4 | 1411 | 20 | 508 | 583⁄4 1492 | 151⁄4 | 387 | 521⁄4 1327 | 521⁄4 1327 | 153⁄4 | 400 | 4/6 102/152 | 197/89.4 | ||||||

54 | 65 | 246 | 55,000 | 16.1 |

| 43 | 51 | 193 | 781⁄4 | 1988 | 22 | 559 | 62 | 1575 | 151⁄4 | 387 | 56 | 1422 | 56 | 1422 | 153⁄4 | 400 | 4/6 102/152 | 243/110 | |||

62 | 75 | 284 | 60,000 | 17.6 |

| 47 | 56 | 212 | 751⁄2 | 1918 | 241⁄2 | 622 | 59 | 1499 | 151⁄4 | 387 | 52 | 1321 | 52 | 1320 | 161⁄2 | 419 | 4/6 102/152 | 281/127 | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

All propane gas heaters are equipped with Cast Iron Burner. Change suffix “BN” to “CX”.

Suitable for Water (Potable) Heating and Space Heating

Toxic chemicals, such as those used for boiler treatment, shall NEVER be introduced into this system. This unit may NEVER be connected to any existing heating system or component(s) previously used with a

General

All gas water heaters are certified at 300 PSI (2068 kPa) test pressure and 150 PSI (1034 kPa) working pressure. All water connections are 3⁄4" (19mm) NPT on

8" (703mm) centers on top of unit, all gas connections 1⁄2" (13mm). All models design certified by CSA International (formerly AGA and CGA). Recovery based on rated efficiency.

Meets NAECA requirements. All natural gas models meet SCAQMD requirements.

Dimensions and specifications subject to change without notice in accordance with our policy of continuous product improvement.

Sample Specification

The water heater shall be a Bradford White model with a rated storage capacity of not less than _______ gallons (liters), a minimum gas input of _______ BTUH (KWH), and a

minimum recovery of _______ GPH (LPH) at 100°F (56°C) temperature rise. It shall be

design certified by CSA International (formerly AGA and CGA). The tank shall be lined with Vitraglas® vitreous enamel. The tank shall have one extruded magnesium anode rod. The heater shall be insulated with

Vitraglas® and Hydrojet® are registered trademarks of Bradford White® Corporation. ©2006, Bradford White Corporation. All rights reserved.

(LP) Propane Gas Inputs

| Recovery at |

| |

50°C Rise and 100°F Rise | |||

| Imp. | U.S. Liters/ | |

GPH | GPH | Hr. | |

38 | 45 | 170 | |

| 44 | 53 | 200 |

Ambler, PA

For U.S. and Canada field service, contact your professional installer or local Bradford White sales representative.

Technical Support/

International:

Fax on Demand:

www.bradfordwhite.com

Mississauga, ON

Sales/Technical Support

www.bradfordwhitecanada.com

PRODUCTS ONLY FOR PROFESSIONALS

Printed in U.S.A.