200MVP, 300MVP specifications

The Brady 300MVP and 200MVP label printers are innovative devices that cater to various labeling needs, particularly in industrial environments. These printers stand out due to their cutting-edge technologies, design features, and versatility, making them essential tools for professionals across multiple sectors.One of the primary characteristics of the Brady 300MVP and 200MVP is their ease of use. Both models are equipped with intuitive interfaces that simplify navigation and operation. Users can quickly select from a range of label templates or create custom labels, thanks to the user-friendly touchscreen displays. This feature significantly reduces the learning curve and increases productivity, allowing operators to focus on their tasks rather than on complicated equipment.

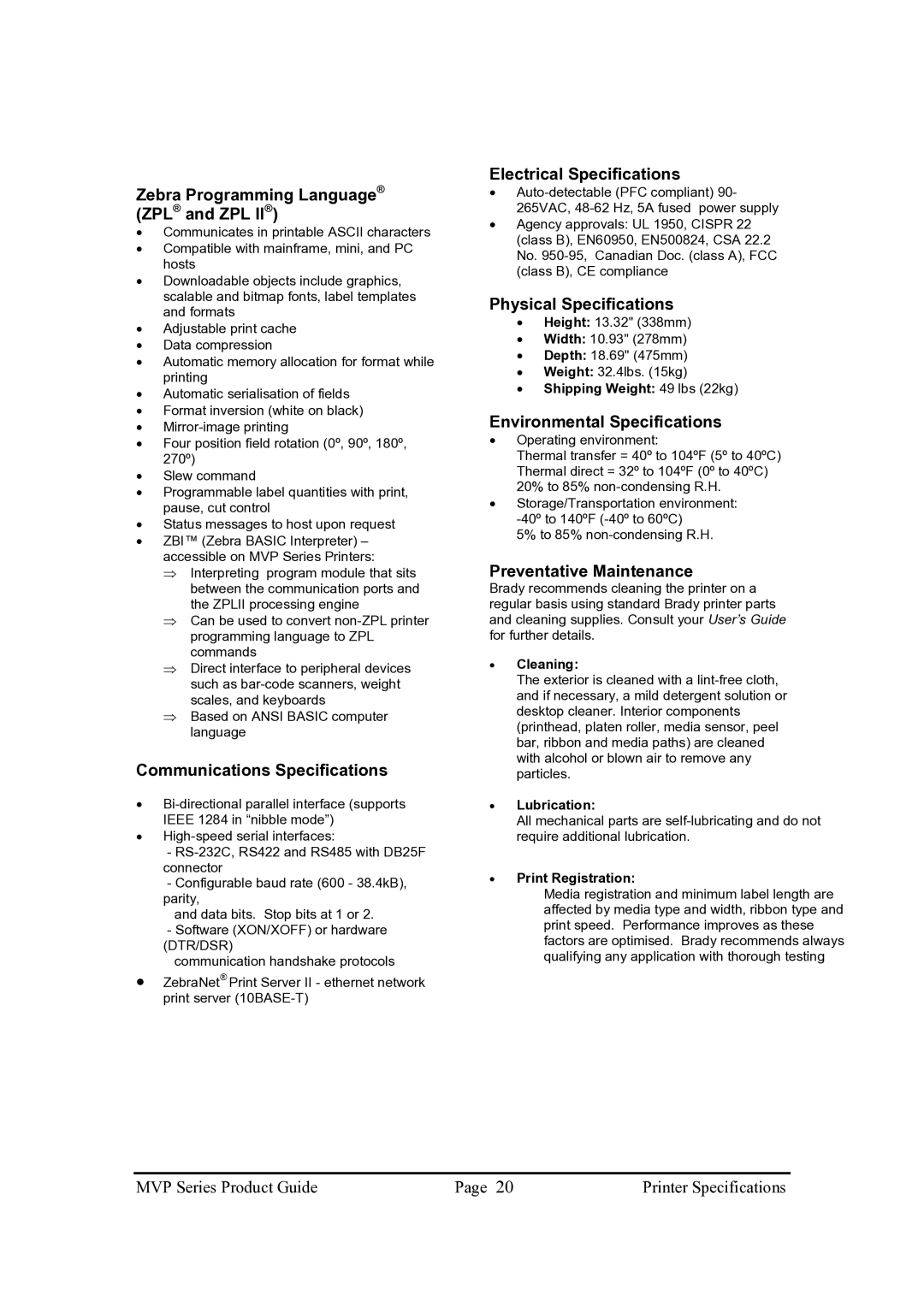

These printers boast advanced connectivity options, including USB, Bluetooth, and Wi-Fi, enabling seamless integration with other devices and networks. This connectivity allows users to print labels directly from their smartphones, tablets, or computers, enhancing efficiency in fast-paced environments. Furthermore, the ability to connect to cloud services ensures that important labeling templates and designs are always accessible.

The Brady 300MVP and 200MVP printers are designed to handle various label materials, including vinyl, polyester, and polyimide, suited for various applications such as asset identification, safety signage, and wire marking. Additionally, these printers are capable of producing labels in various sizes and colors, offering flexibility to meet specific labeling requirements.

Durability is another hallmark of the Brady label printers. Constructed to withstand demanding conditions, they are resistant to chemicals, moisture, and UV light, ensuring that labels remain intact and legible even in harsh environments. This resilience is crucial for industries such as manufacturing, construction, and electrical work, where durability is paramount.

Another key feature is the ability to print high-resolution barcodes and QR codes, facilitating better inventory management and tracking. This functionality is vital in today’s data-driven workplace, as it streamlines operations and enhances efficiency.

In summary, the Brady 300MVP and 200MVP label printers offer a powerful combination of user-friendliness, connectivity, and durability. With their advanced features and versatility, these printers are ideal solutions for professionals requiring reliable labeling solutions in various industrial applications. Their commitment to quality and innovation makes them standout choices in the competitive labeling market.