2800 PSI Pressure Washer

2.If screen is damaged,

3.Place

4.Place

5.Assemble nozzle extension to spray gun.

Purge Pump of Air and

Contaminants

To remove air from the pump, follow these steps:

1.Set up pressure washer as described in “Preparing Pressure Washer For Use”. Connect water supply and turn water ON.

2.Pull trigger on spray gun and hold.

3.When water stream is steady and constant, engage safety latch.

To remove contaminants from the pump, follow these steps:

1.Set up pressure washer as described in “Preparing Pressure Washer For Use”. Connect water supply and turn water ON.

2.Start engine according to instructions in “To Start Pressure Washer”.

3.Remove nozzle extension from spray gun.

4.Squeeze trigger on spray gun and hold.

5.When water stream is steady and constant, engage safety latch and reattach nozzle extension.

Nozzle Maintenance

A pulsing sensation felt while squeezing the spray gun trigger may be caused by excessive pump pressure.The principal cause of excessive pump pressure is a spray tip clogged or restricted with foreign materials, such as dirt, etc.To correct the problem, immediately clean the spray tip using the tools included with your pressure washer and follow these instructions:

1.Shut off engine and turn off water supply.

2.Remove spray tip from end of nozzle extension.

3.Remove

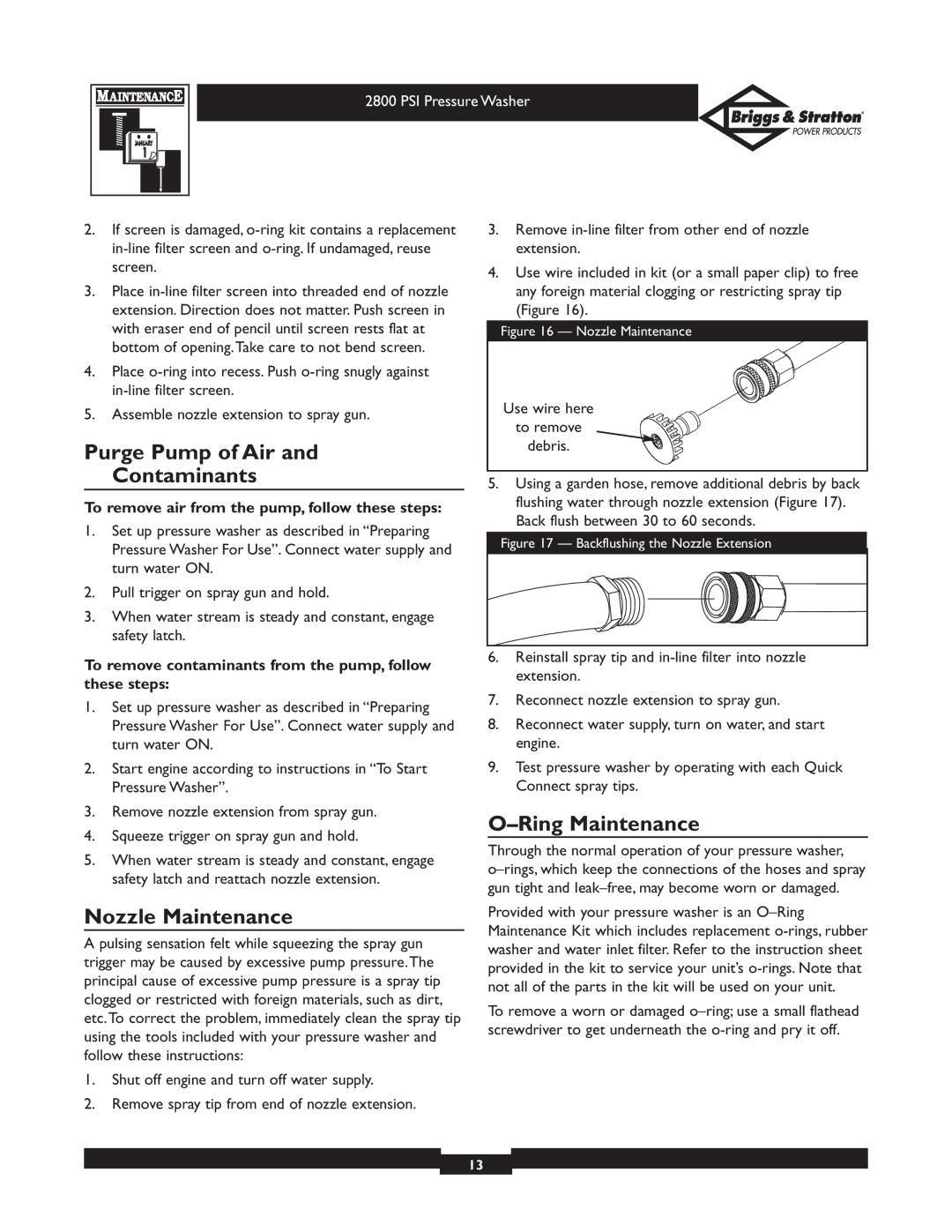

4.Use wire included in kit (or a small paper clip) to free any foreign material clogging or restricting spray tip (Figure 16).

Figure 16 — Nozzle Maintenance

Use wire here

to remove

debris.

5.Using a garden hose, remove additional debris by back flushing water through nozzle extension (Figure 17). Back flush between 30 to 60 seconds.

Figure 17 — Backflushing the Nozzle Extension

6.Reinstall spray tip and

7.Reconnect nozzle extension to spray gun.

8.Reconnect water supply, turn on water, and start engine.

9.Test pressure washer by operating with each Quick Connect spray tips.

O–Ring Maintenance

Through the normal operation of your pressure washer,

Provided with your pressure washer is an

To remove a worn or damaged

13