Maintenance

Maintenance Schedule

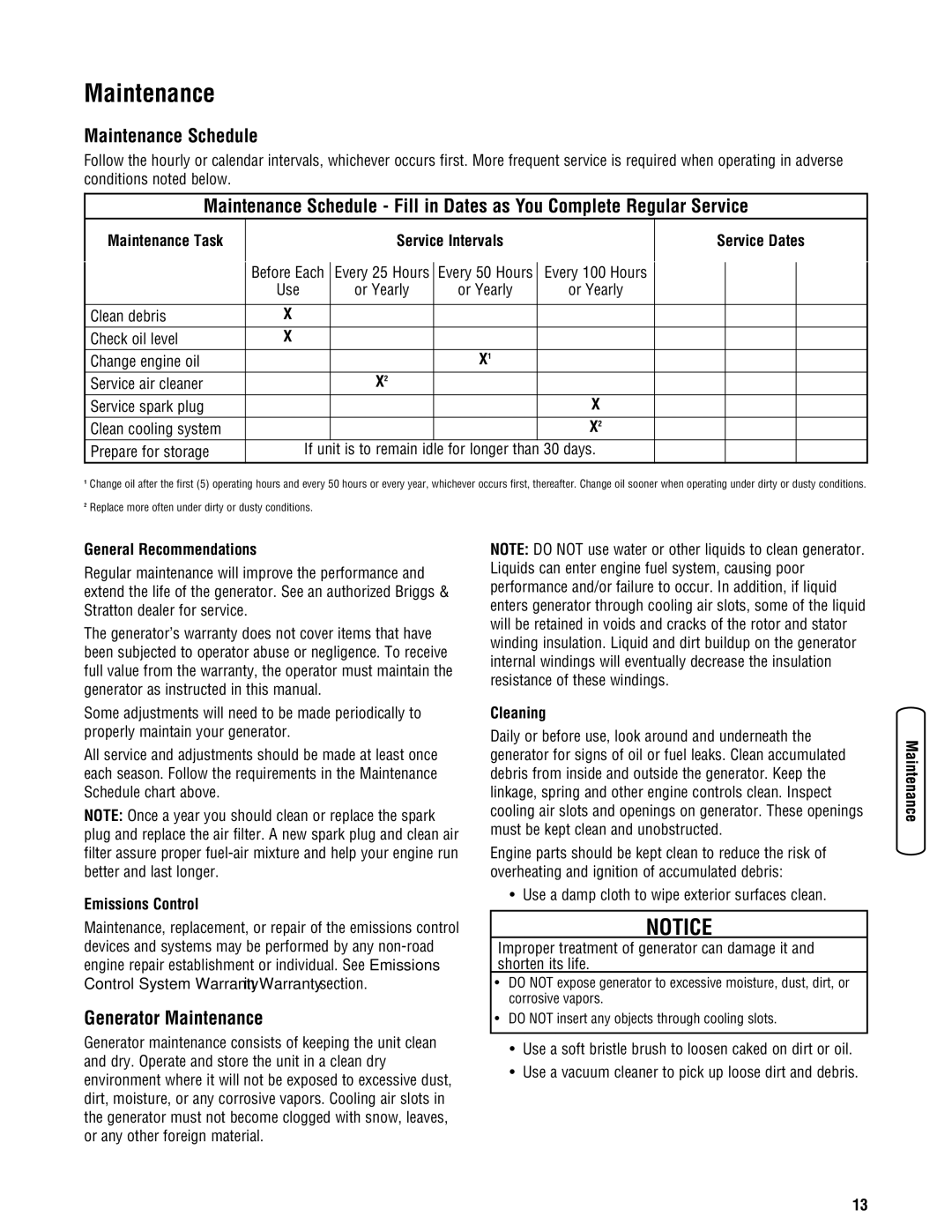

Follow the hourly or calendar intervals, whichever occurs first. More frequent service is required when operating in adverse conditions noted below.

Maintenance Schedule - Fill in Dates as You Complete Regular Service

Maintenance Task |

|

| Service Intervals |

|

| Service Dates | ||||

| Before Each |

| Every 25 Hours |

| Every 50 Hours |

| Every 100 Hours |

|

|

|

|

|

|

|

|

|

| ||||

| Use |

| or Yearly |

| or Yearly |

| or Yearly |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Clean debris | X |

|

|

|

|

|

|

|

|

|

Check oil level | X |

|

|

|

|

|

|

|

|

|

Change engine oil |

|

|

|

| X1 |

|

|

|

|

|

Service air cleaner |

|

| X2 |

|

|

|

|

|

|

|

Service spark plug |

|

|

|

|

|

| X |

|

|

|

Clean cooling system |

|

|

|

|

|

| X2 |

|

|

|

Prepare for storage | If unit is to remain idle for longer than 30 days. |

|

|

| ||||||

1Change oil after the first (5) operating hours and every 50 hours or every year, whichever occurs first, thereafter. Change oil sooner when operating under dirty or dusty conditions.

2Replace more often under dirty or dusty conditions.

General Recommendations

Regular maintenance will improve the performance and extend the life of the generator. See an authorized Briggs & Stratton dealer for service.

The generator’s warranty does not cover items that have been subjected to operator abuse or negligence. To receive full value from the warranty, the operator must maintain the generator as instructed in this manual.

Some adjustments will need to be made periodically to properly maintain your generator.

All service and adjustments should be made at least once each season. Follow the requirements in the Maintenance Schedule chart above.

NOTE: Once a year you should clean or replace the spark plug and replace the air filter. A new spark plug and clean air filter assure proper

Emissions Control

Maintenance, replacement, or repair of the emissions control devices and systems may be performed by any

Generator Maintenance

Generator maintenance consists of keeping the unit clean and dry. Operate and store the unit in a clean dry environment where it will not be exposed to excessive dust, dirt, moisture, or any corrosive vapors. Cooling air slots in the generator must not become clogged with snow, leaves, or any other foreign material.

NOTE: DO NOT use water or other liquids to clean generator. Liquids can enter engine fuel system, causing poor performance and/or failure to occur. In addition, if liquid enters generator through cooling air slots, some of the liquid will be retained in voids and cracks of the rotor and stator winding insulation. Liquid and dirt buildup on the generator internal windings will eventually decrease the insulation resistance of these windings.

Cleaning

Daily or before use, look around and underneath the generator for signs of oil or fuel leaks. Clean accumulated debris from inside and outside the generator. Keep the linkage, spring and other engine controls clean. Inspect cooling air slots and openings on generator. These openings must be kept clean and unobstructed.

Engine parts should be kept clean to reduce the risk of overheating and ignition of accumulated debris:

• Use a damp cloth to wipe exterior surfaces clean.

NOTICE

Improper treatment of generator can damage it and shorten its life.

•DO NOT expose generator to excessive moisture, dust, dirt, or corrosive vapors.

•DO NOT insert any objects through cooling slots.

•Use a soft bristle brush to loosen caked on dirt or oil.

•Use a vacuum cleaner to pick up loose dirt and debris.

13