Service

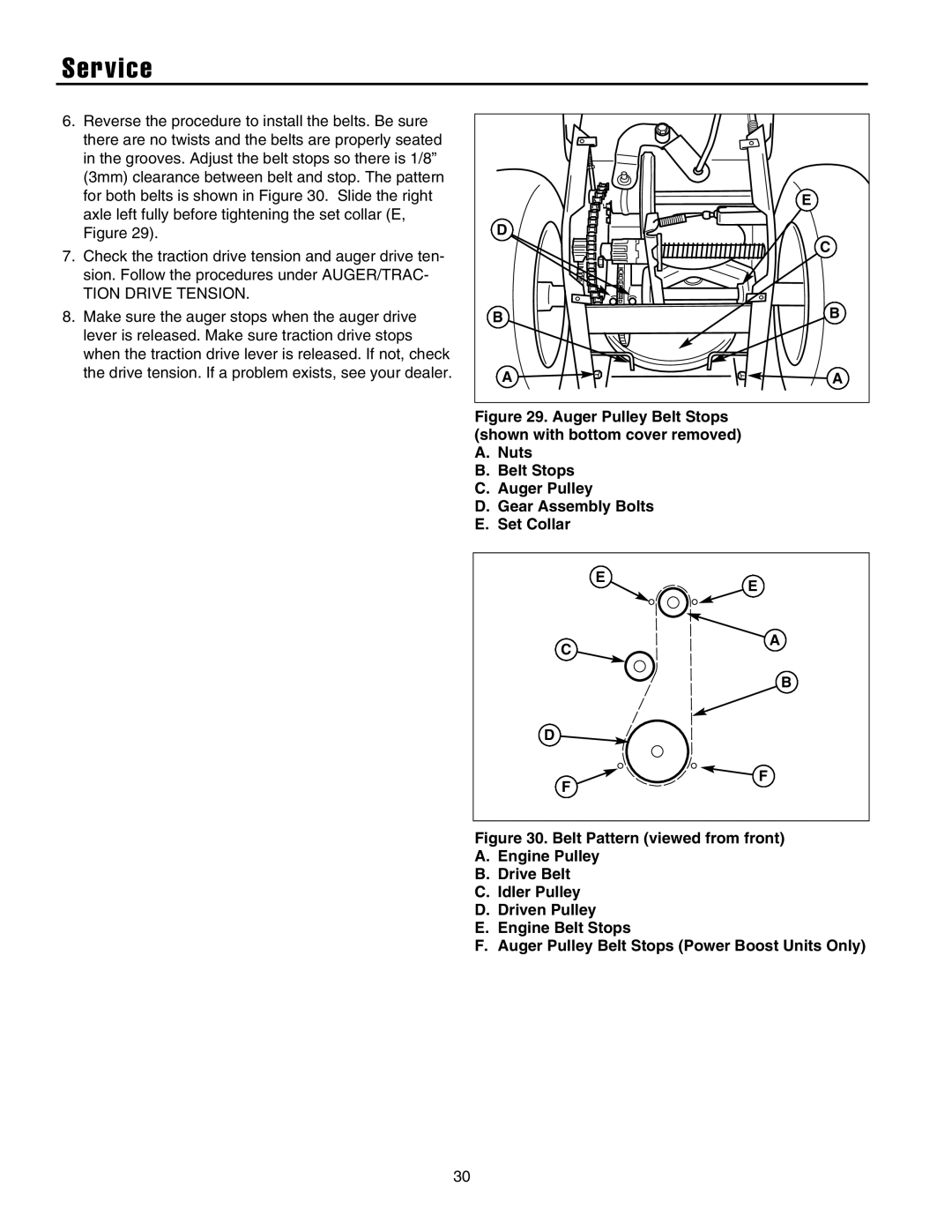

6.Reverse the procedure to install the belts. Be sure there are no twists and the belts are properly seated in the grooves. Adjust the belt stops so there is 1/8” (3mm) clearance between belt and stop. The pattern for both belts is shown in Figure 30. Slide the right axle left fully before tightening the set collar (E, Figure 29).

7.Check the traction drive tension and auger drive ten- sion. Follow the procedures under AUGER/TRAC-

TION DRIVE TENSION.

8.Make sure the auger stops when the auger drive lever is released. Make sure traction drive stops when the traction drive lever is released. If not, check the drive tension. If a problem exists, see your dealer.

| E |

D | C |

| |

B | B |

A | A |

Figure 29. Auger Pulley Belt Stops (shown with bottom cover removed)

A.Nuts

B.Belt Stops

C.Auger Pulley

D.Gear Assembly Bolts

E.Set Collar

E

E

C

D

A

B

F

F

Figure 30. Belt Pattern (viewed from front)

A.Engine Pulley

B.Drive Belt

C.Idler Pulley

D.Driven Pulley

E.Engine Belt Stops

F.Auger Pulley Belt Stops (Power Boost Units Only)

30