Regular Maintenance

CHECK / LUBRICATE FREE-HAND LINKAGE

Check the function of the

Lubricate as shown in Figures 16-17.

IMPORTANT NOTE

If the controls do not function properly, lubricate them. If lubrication does not rectify the problem, see your dealer. Under no circumstances should the unit be used if the controls are not functioning properly.

A |

Figure 16. Lubricate Free-Hand™ Control Linkage A. DO NOT Lubricate Deflector Control

IMPORTANT NOTE

It is very important that grease fittings on the auger shaft are lubricated regularly. If auger rusts to shaft, damage to worm gear may occur if shear pins do not break.

Figure 17. Lubricate Free Hand Control

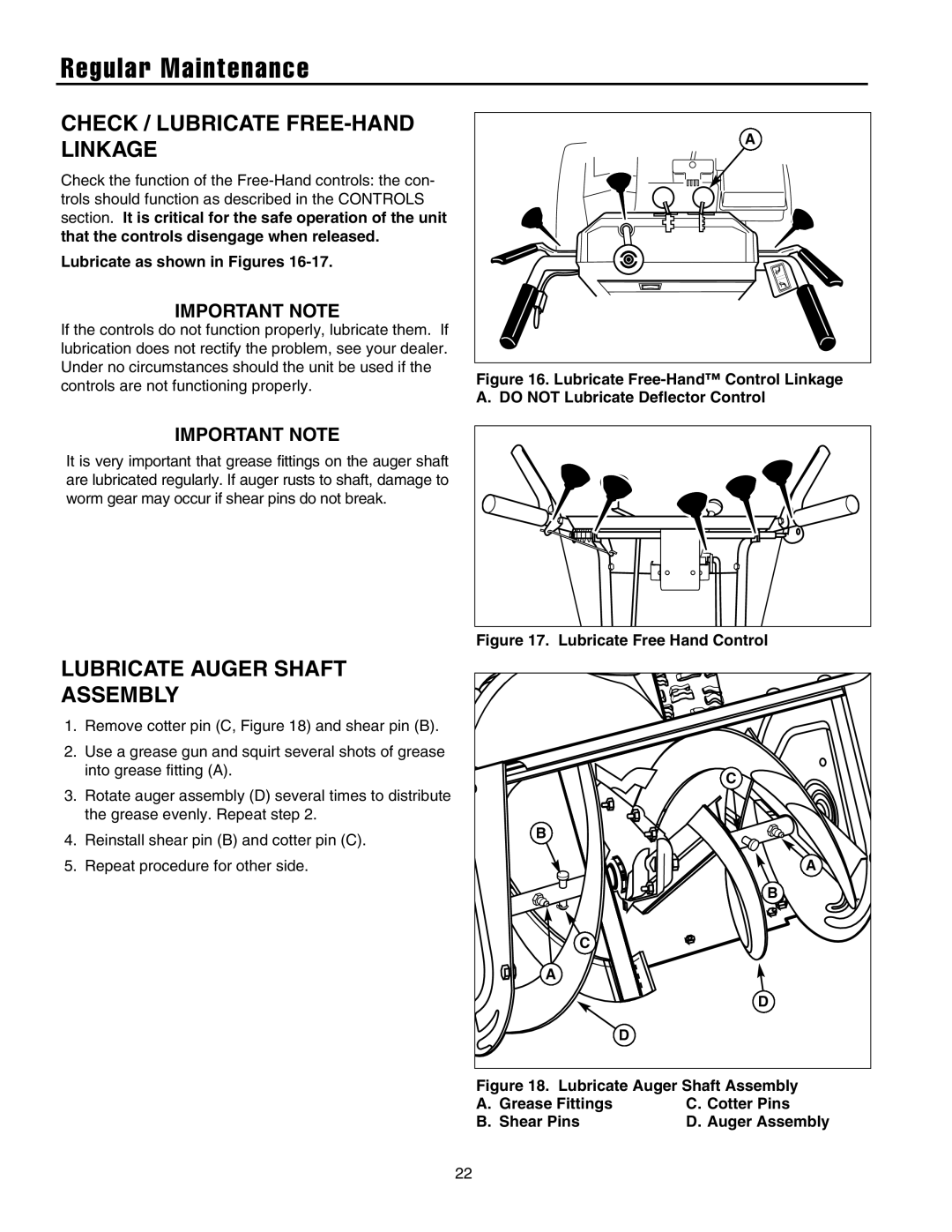

LUBRICATE AUGER SHAFT

ASSEMBLY

1.Remove cotter pin (C, Figure 18) and shear pin (B).

2.Use a grease gun and squirt several shots of grease into grease fitting (A).

3.Rotate auger assembly (D) several times to distribute the grease evenly. Repeat step 2.

4.Reinstall shear pin (B) and cotter pin (C).

5.Repeat procedure for other side.

C |

B |

A |

B |

C |

A |

D |

D |

Figure 18. Lubricate Auger Shaft Assembly

A. | Grease Fittings | C. Cotter Pins |

B. | Shear Pins | D. Auger Assembly |

22