Assembly

Your generator requires some assembly and is ready for use after it has been properly serviced with the recommended oil and fuel.

If you have any problems with the assembly of your generator, please call the generator helpline at

Unpack Generator

1.Set the carton on a rigid, flat surface.

2.Remove everything from carton except generator.

3.Open carton completely by cutting each corner from top to bottom.

4.Leave generator on carton to install wheel kit.

Shipment Contents

The generator is supplied with:

•Operator’s manual

•Wheel kit

•Product registration card

Install Wheel Kit

NOTE: Wheel kit is not intended for

You will need the following tools to install these components:

•13 mm wrench

•Socket wrench with a 13 mm socket

•Pliers

•Safety glasses

Install the wheel kit as follows:

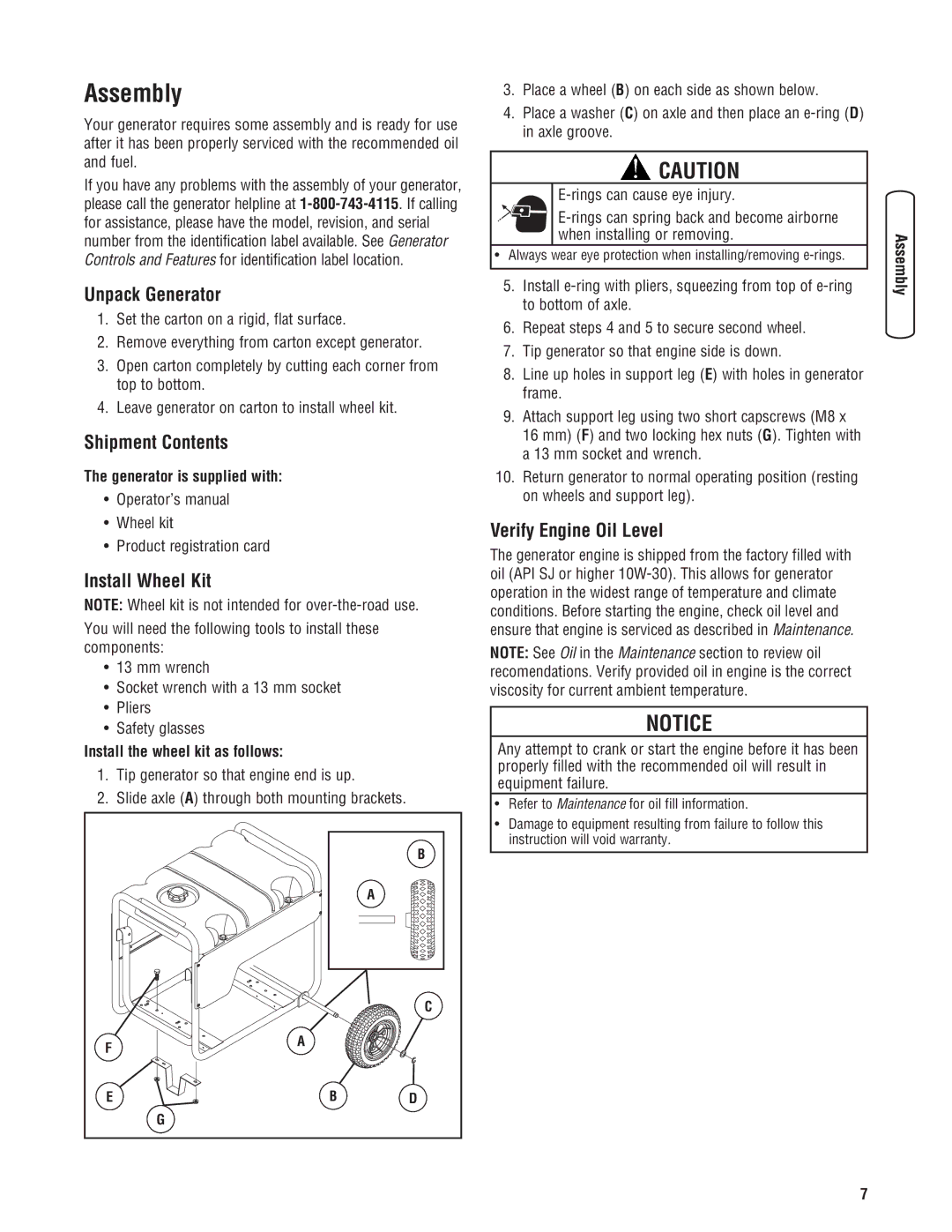

1.Tip generator so that engine end is up.

2.Slide axle (A) through both mounting brackets.

B

A

C

FA

E ![]() BD G

BD G

3.Place a wheel (B) on each side as shown below.

4.Place a washer (C) on axle and then place an

![]() CAUTION

CAUTION

•Always wear eye protection when installing/removing

5.Install

6.Repeat steps 4 and 5 to secure second wheel.

7.Tip generator so that engine side is down.

8.Line up holes in support leg (E) with holes in generator frame.

9.Attach support leg using two short capscrews (M8 x 16 mm) (F) and two locking hex nuts (G). Tighten with a 13 mm socket and wrench.

10.Return generator to normal operating position (resting on wheels and support leg).

Verify Engine Oil Level

The generator engine is shipped from the factory filled with oil (API SJ or higher

NOTE: See Oil in the Maintenance section to review oil recomendations. Verify provided oil in engine is the correct viscosity for current ambient temperature.

NOTICE

Any attempt to crank or start the engine before it has been properly filled with the recommended oil will result in equipment failure.

•Refer to Maintenance for oil fill information.

•Damage to equipment resulting from failure to follow this instruction will void warranty.

7