INSTALLING THE

INSTALLING THE

DUCTWORK

NOTE

THESE INSTRUCTIONS WILL FOLLOW THE PLANS MADE ON PAGE 2. START AT THE EX- TERIOR AND RUN THE DUCT BACK TO THE RANGE HOOD.

FOR BEST PERFORMANCE OF YOUR RANGE HOOD, USE THE SHORTEST POSSIBLE DUCT RUN AND A MINIMUM NUMBER OF ELBOWS.

NEVER VENT A RANGE HOOD INTO AN AT- TIC SPACE BECAUSE A BUILDUP OF GREASE WILL BECOME A FIRE HAZARD.

USE ONLY METAL DUCTWORK (DO NOT USE PLASTIC DUCT). ASSEMBLE SECURELY SO THAT IN CASE OF A GREASE FIRE ON THE RANGE, THE FIRE WILL BE CONTAINED IN- SIDE METAL DUCT WORK.

IT IS A GOOD PRACTICE TO TAPE ALL DUCT CONNECTIONS, MAKING THEM BOTH SE- CURE AND AIR TIGHT.

15.Follow appropriate directions below for type of duct work you are installing:

WALL CAPS (FIG. 9)

Use a saber saw to cut a hole slightly larger than duct so duct will line up easily with hood. Install casing strips on outside walls finished in siding. Assemble the duct work and tape all joints. Run duct work back to hood. Fasten wall cap to last section of duct and nail or screw cap to wall. Seal all around flange on wall cap with caulking com- pound. Make sure that enough duct runs into the room so that the duct will overlap the damper/duct connector by 3/4" when the hood is installed.

ROOF CAPS

Cut hole in roof slightly larger than duct so duct will line up easily with hood. Trim shingles around hole so that they will fit snugly around hood of cap when cap is installed. Assemble the duct work and tape all joints. Run the duct work down to hood. Trim duct parallel to roof pitch, leaving 3/4" of duct projecting above roof. Seal all around duct with roof cement.

Install roof cap, inserting back edge of cap under shingles. Seal around cap with roof cement and seal all nail heads and shingles which were cut or lifted.

Make sure that enough duct runs into the room so that the duct will overlap the damper/duct connec- tor by 3/4" when the hood is put into place.

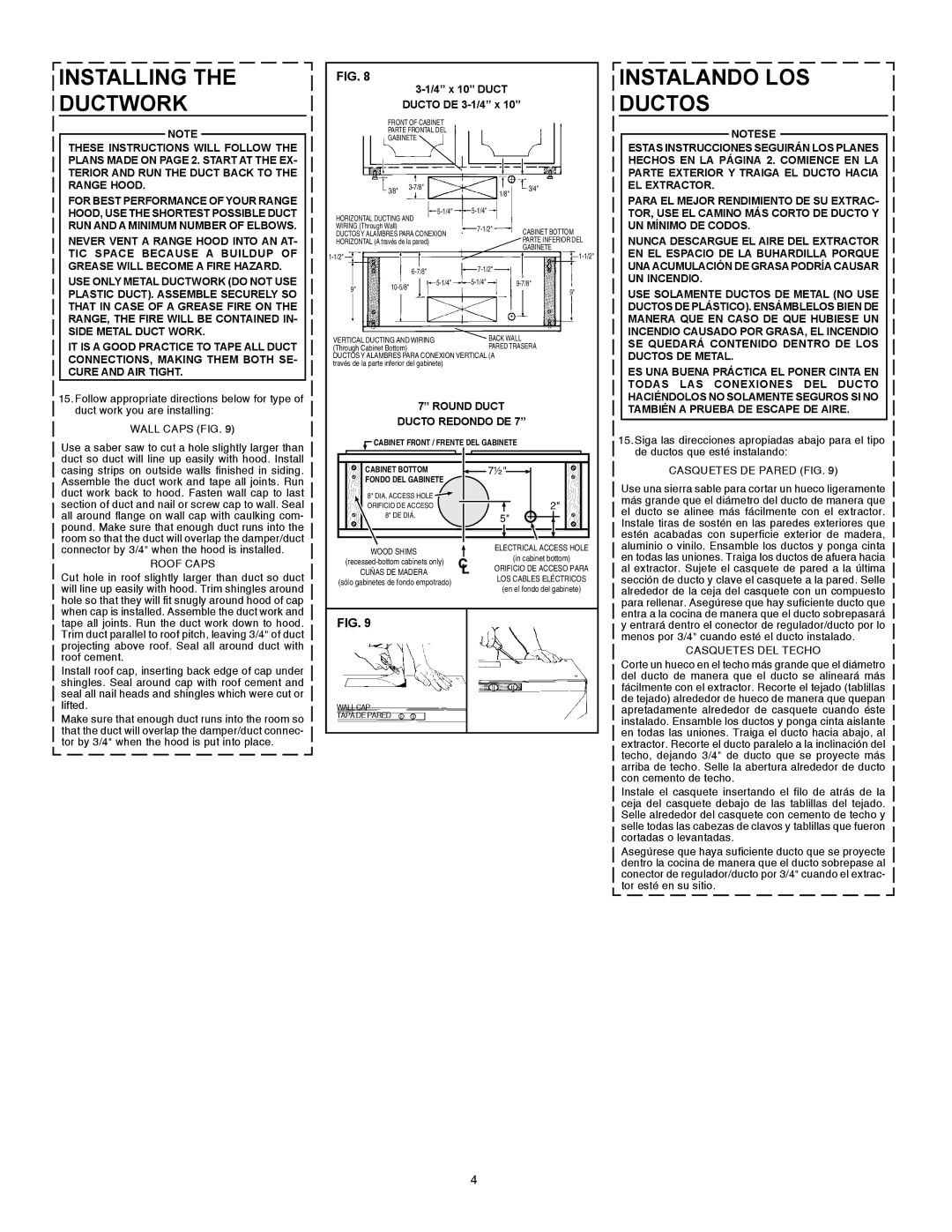

FIG. 8

3-1/4” x 10” DUCT

DUCTO DE 3-1/4” x 10”

FRONT OF CABINET

PARTE FRONTAL DEL

GABINETE

| | | | 3/8" | | | 3-7/8" | | | | | | | | | | | | | | 3/4" | | | | |

| | | | | | | | | | | | | | | | 1/8" | |

| | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | |

| HORIZONTAL DUCTING AND | 5-1/4" | | 5-1/4" | | | | | | | | | | | |

| | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | |

| WIRING (Through Wall) | | | | | | | | 7-1/2" | | | | CABINET BOTTOM |

| DUCTOS Y ALAMBRES PARA CONEXION | | | | | |

| | | | | | | | | |

| HORIZONTAL (A través de la pared) | | | | | | | | | | | PARTE INFERIOR DEL |

| | | | | | | | | | | | | | | | | | | | | | GABINETE |

1-1/2" | | | | | | | | | | | | | | | | | | | | | | | | | | 1-1/2" |

| | | | | | | | | | | | | | | 7-1/2" | | | | | | | | | |

| | | | | | | | 6 | -7/8" | | | | | | | | | | | |

| | | | | | | | | | | | 5-1/4" | | 5-1/4" | | | | | |

| | | | | | | | | | | | | | 9-7/8" | | | | |

| | | | 1 | 0-5/8 | " | | | | | | | | |

| | 9" | | | | | | | | | | | BACK WALL | | | | 9" | | |

| | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | |

| VERTICAL DUCTING AND WIRING | | | | | | |

| | | | | | | | | | | |

| | | | | | | | | | | |

| (Through Cabinet Bottom) | | | | | | | | | | PARED TRASERA |

DUCTOS Y ALAMBRES PARA CONEXION VERTICAL (A través de la parte inferior del gabinete)

7” ROUND DUCT

DUCTO REDONDO DE 7”

CABINET FRONT / FRENTE DEL GABINETE

CABINET FRONT / FRENTE DEL GABINETE

| CABINET BOTTOM | 7½" |

| FONDO DEL GABINETE | |

| 8" DIA. ACCESS HOLE | 2" |

| ORIFICIO DE ACCESO |

| 8" DE DIÁ. | 5" |

| |

| WOOD SHIMS | ELECTRICAL ACCESS HOLE |

| (in cabinet bottom) |

| (recessed-bottom cabinets only) |

| ORIFICIO DE ACCESO PARA |

| CUÑAS DE MADERA |

| LOS CABLES ELÉCTRICOS |

| (sólo gabinetes de fondo empotrado) |

| (en el fondo del gabinete) |

| |

FIG. 9

WALL CAP

TAPA DE PARED

INSTALANDO LOS

INSTALANDO LOS

DUCTOS

NOTESE

ESTAS INSTRUCCIONES SEGUIRÁN LOS PLANES HECHOS EN LA PÁGINA 2. COMIENCE EN LA PARTE EXTERIOR Y TRAIGA EL DUCTO HACIA EL EXTRACTOR.

PARA EL MEJOR RENDIMIENTO DE SU EXTRAC- TOR, USE EL CAMINO MÁS CORTO DE DUCTO Y UN MÍNIMO DE CODOS.

NUNCA DESCARGUE EL AIRE DEL EXTRACTOR EN EL ESPACIO DE LA BUHARDILLA PORQUE UNA ACUMULACIÓN DE GRASA PODRÍA CAUSAR UN INCENDIO.

USE SOLAMENTE DUCTOS DE METAL (NO USE DUCTOS DE PLÁSTICO). ENSÁMBLELOS BIEN DE MANERA QUE EN CASO DE QUE HUBIESE UN INCENDIO CAUSADO POR GRASA, EL INCENDIO SE QUEDARÁ CONTENIDO DENTRO DE LOS DUCTOS DE METAL.

ES UNA BUENA PRÁCTICA EL PONER CINTA EN TODAS LAS CONEXIONES DEL DUCTO HACIÉNDOLOS NO SOLAMENTE SEGUROS SI NO TAMBIÉN A PRUEBA DE ESCAPE DE AIRE.

15.Siga las direcciones apropiadas abajo para el tipo de ductos que esté instalando:

CASQUETES DE PARED (FIG. 9)

Use una sierra sable para cortar un hueco ligeramente más grande que el diámetro del ducto de manera que el ducto se alinee más fácilmente con el extractor. Instale tiras de sostén en las paredes exteriores que estén acabadas con superficie exterior de madera, aluminio o vinilo. Ensamble los ductos y ponga cinta en todas las uniones. Traiga los ductos de afuera hacia al extractor. Sujete el casquete de pared a la última sección de ducto y clave el casquete a la pared. Selle alrededor de la ceja del casquete con un compuesto para rellenar. Asegúrese que hay suficiente ducto que entra a la cocina de manera que el ducto sobrepasará y entrará dentro el conector de regulador/ducto por lo menos por 3/4" cuando esté el ducto instalado.

CASQUETES DEL TECHO

Corte un hueco en el techo más grande que el diámetro del ducto de manera que el ducto se alineará más fácilmente con el extractor. Recorte el tejado (tablillas de tejado) alrededor de hueco de manera que quepan apretadamente alrededor de casquete cuando éste instalado. Ensamble los ductos y ponga cinta aislante en todas las uniones. Traiga el ducto hacia abajo, al extractor. Recorte el ducto paralelo a la inclinación del techo, dejando 3/4" de ducto que se proyecte más arriba de techo. Selle la abertura alrededor de ducto con cemento de techo.

Instale el casquete insertando el filo de atrás de la ceja del casquete debajo de las tablillas del tejado. Selle alrededor del casquete con cemento de techo y selle todas las cabezas de clavos y tablillas que fueron cortadas o levantadas.

Asegúrese que haya suficiente ducto que se proyecte dentro la cocina de manera que el ducto sobrepase al conector de regulador/ducto por 3/4" cuando el extrac- tor esté en su sitio.