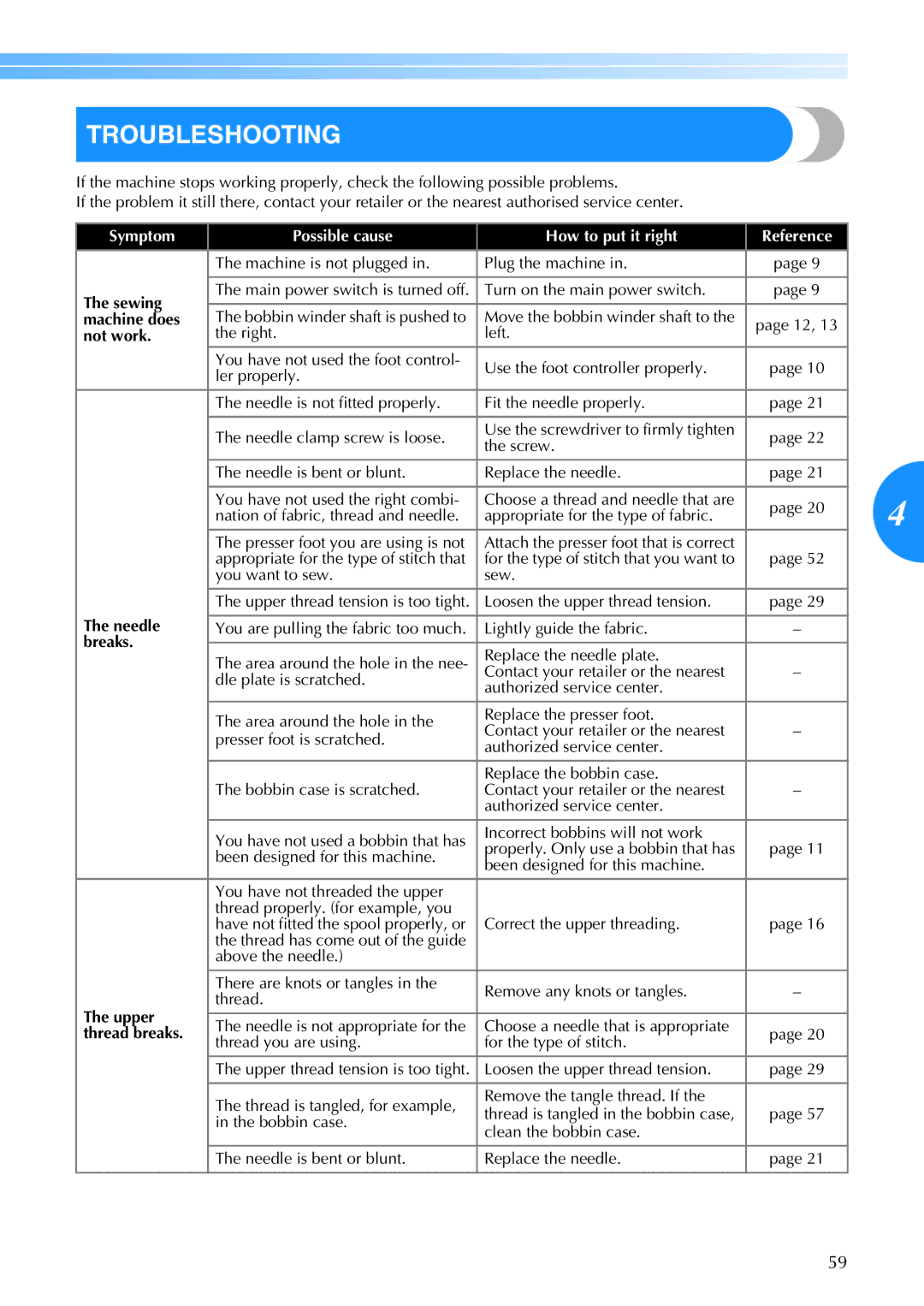

TROUBLESHOOTING

If the machine stops working properly, check the following possible problems.

If the problem it still there, contact your retailer or the nearest authorised service center.

Symptom | Possible cause | How to put it right | Reference |

|

| The machine is not plugged in. | Plug the machine in. | page 9 |

|

|

|

|

|

|

The sewing | The main power switch is turned off. | Turn on the main power switch. | page 9 |

|

|

|

|

| |

The bobbin winder shaft is pushed to | Move the bobbin winder shaft to the |

|

| |

machine does | page 12, 13 |

| ||

not work. | the right. | left. |

| |

|

| |||

| You have not used the foot control- | Use the foot controller properly. | page 10 |

|

| ler properly. |

| ||

|

|

|

| |

| The needle is not fitted properly. | Fit the needle properly. | page 21 |

|

|

|

|

|

|

| The needle clamp screw is loose. | Use the screwdriver to firmly tighten | page 22 |

|

| the screw. |

| ||

|

|

|

| |

| The needle is bent or blunt. | Replace the needle. | page 21 |

|

|

|

|

|

|

| You have not used the right combi- | Choose a thread and needle that are | page 20 | 4 |

| nation of fabric, thread and needle. | appropriate for the type of fabric. | ||

|

| |||

| The presser foot you are using is not | Attach the presser foot that is correct |

|

|

| appropriate for the type of stitch that | for the type of stitch that you want to | page 52 |

|

| you want to sew. | sew. |

|

|

| The upper thread tension is too tight. | Loosen the upper thread tension. | page 29 |

|

The needle |

|

|

|

|

You are pulling the fabric too much. | Lightly guide the fabric. | – |

| |

breaks. |

|

|

|

|

The area around the hole in the nee- | Replace the needle plate. |

|

| |

|

|

| ||

| Contact your retailer or the nearest | – |

| |

| dle plate is scratched. | authorized service center. |

|

|

|

|

|

| |

|

|

|

|

|

| The area around the hole in the | Replace the presser foot. |

|

|

| Contact your retailer or the nearest | – |

| |

| presser foot is scratched. |

| ||

| authorized service center. |

|

| |

|

|

|

| |

|

|

|

|

|

|

| Replace the bobbin case. |

|

|

| The bobbin case is scratched. | Contact your retailer or the nearest | – |

|

|

| authorized service center. |

|

|

| You have not used a bobbin that has | Incorrect bobbins will not work |

|

|

| properly. Only use a bobbin that has | page 11 |

| |

| been designed for this machine. |

| ||

| been designed for this machine. |

|

| |

|

|

|

| |

|

|

|

|

|

| You have not threaded the upper |

|

|

|

| thread properly. (for example, you |

|

|

|

| have not fitted the spool properly, or | Correct the upper threading. | page 16 |

|

| the thread has come out of the guide |

|

|

|

| above the needle.) |

|

|

|

| There are knots or tangles in the | Remove any knots or tangles. | – |

|

| thread. |

| ||

The upper |

|

|

| |

The needle is not appropriate for the | Choose a needle that is appropriate |

|

| |

thread breaks. | page 20 |

| ||

thread you are using. | for the type of stitch. |

| ||

|

|

| ||

|

|

|

|

|

| The upper thread tension is too tight. | Loosen the upper thread tension. | page 29 |

|

|

|

|

|

|

| The thread is tangled, for example, | Remove the tangle thread. If the |

|

|

| thread is tangled in the bobbin case, | page 57 |

| |

| in the bobbin case. |

| ||

| clean the bobbin case. |

|

| |

|

|

|

| |

|

|

|

|

|

| The needle is bent or blunt. | Replace the needle. | page 21 |

|

|

|

|

|

|

59