Form No. 6440 (5/00)

TM BRYAN STEAM

TM BRYAN STEAM

Separable Tank Tray Type Boiler Feedwater Deaerators

Capacities 70,000 to 300,000 PPH (2030 to 8695 BHP)

Performance Features

• Oxygen removal to .005 cc/l (7 PPB)

• CO2 removal to 0% measurable

• Reduce chemical costs

• Reduce boiler and system corrosion

•

• Improve boiler efficiency

• Quick equipment payback, compared to chemical oxygen removal

Construction Features

• Constructed to ASME Section VIII, Division I for 50 PSIG

• Hinged tray access door

• Standard 10 minutes deaerated water storage

• Easily accessible manway in storage tank

• All internal surfaces that contact undeaerated water are constructed of type 304L stainless steel

• Internal direct contact vent condenser for minimum steam loss

• Structural steel stand/pump platform

•

• Available as completely packaged unit including pumps and control panel

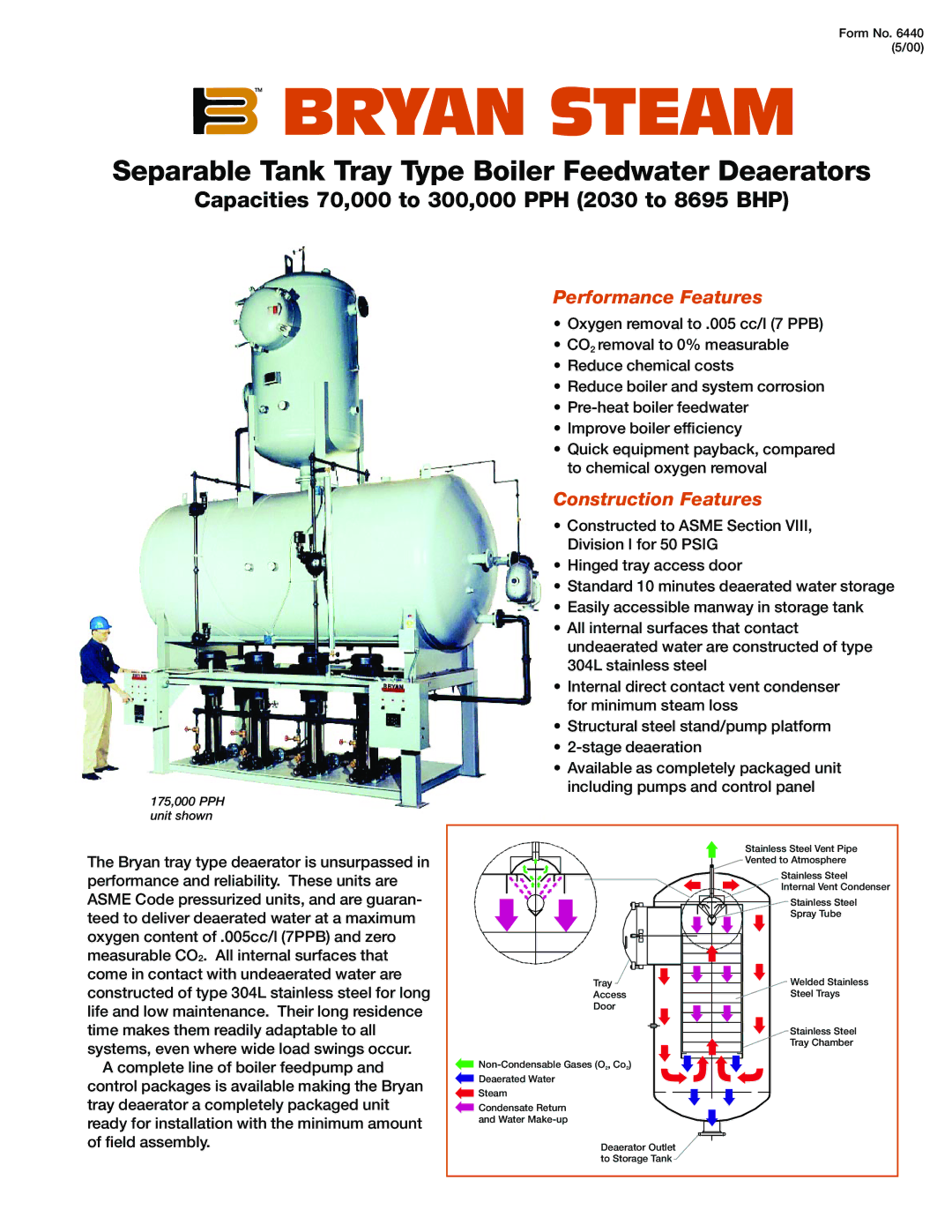

175,000 PPH unit shown

The Bryan tray type deaerator is unsurpassed in performance and reliability. These units are ASME Code pressurized units, and are guaran- teed to deliver deaerated water at a maximum oxygen content of .005cc/l (7PPB) and zero measurable CO2. All internal surfaces that come in contact with undeaerated water are constructed of type 304L stainless steel for long life and low maintenance. Their long residence time makes them readily adaptable to all systems, even where wide load swings occur.

A complete line of boiler feedpump and control packages is available making the Bryan tray deaerator a completely packaged unit ready for installation with the minimum amount of field assembly.

| Stainless Steel Vent Pipe |

| Vented to Atmosphere |

| Stainless Steel |

| Internal Vent Condenser |

| Stainless Steel |

| Spray Tube |

Tray | Welded Stainless |

Access | Steel Trays |

Door |

|

| Stainless Steel |

| Tray Chamber |

![]()

![]() Deaerated Water

Deaerated Water

![]() Steam

Steam

![]() Condensate Return

Condensate Return

and Water

Deaerator Outlet to Storage Tank