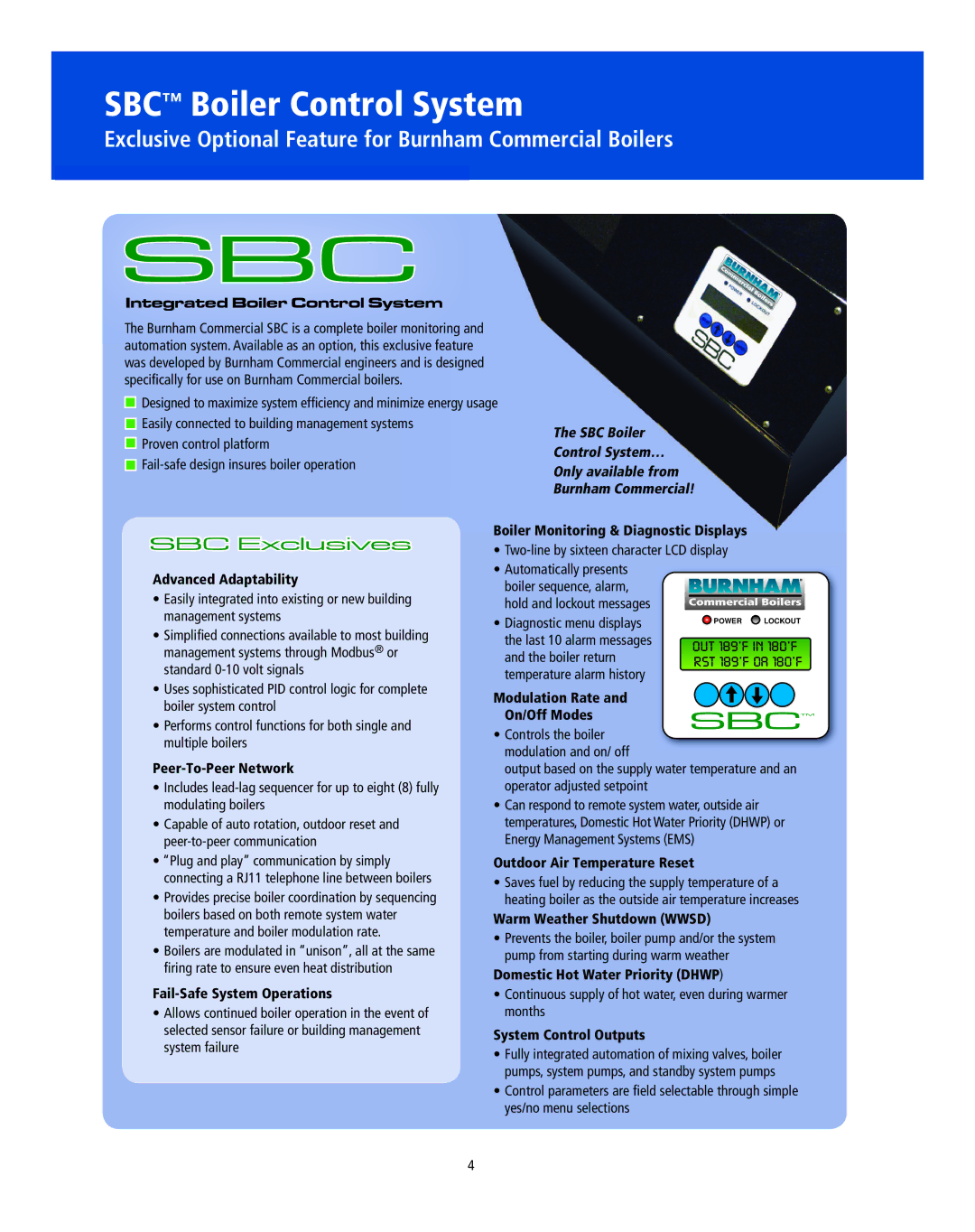

SBCª Boiler Control System

exclusive Optional Feature for Burnham Commercial Boilers

SBC

Integrated Boiler Control System

The Burnham Commercial SBC is a complete boiler monitoring and automation system. Available as an option, this exclusive feature was developed by Burnham Commercial engineers and is designed specifically for use on Burnham Commercial boilers.

Designed to maximize system efficiency and minimize energy usage |

|

|

|

|

| ||

Easily connected to building management systems | The SBC Boiler |

|

|

|

|

| |

Proven control platform |

|

|

|

|

| ||

Control SystemÉ |

|

|

|

|

| ||

|

|

|

|

| |||

Only available from |

|

|

|

|

| ||

|

|

|

|

|

| ||

| Burnham Commercial! |

|

|

|

| ||

SBC Exclusives | Boiler Monitoring & Diagnostic Displays |

|

| ||||

• |

|

| |||||

Advanced Adaptability | • Automatically presents |

|

|

|

|

| |

boiler sequence, alarm, |

|

|

|

|

| ||

• Easily integrated into existing or new building |

|

|

|

|

| ||

hold and lockout messages |

|

| MENU | ENTER |

| ||

|

|

|

|

| |||

management systems |

|

|

|

|

| ||

• Diagnostic menu displays |

| POWER | LOCKOUT | ||||

• Simplified connections available to most building |

| ||||||

the last 10 alarm messages |

|

|

|

|

| ||

management systems through Modbus¨ or |

|

|

|

|

| ||

and the boiler return |

|

|

|

|

| ||

standard |

|

|

|

|

| ||

temperature alarm history |

|

|

|

|

| ||

• Uses sophisticated PID control logic for complete |

|

|

|

|

| ||

Modulation Rate and |

|

|

|

|

| ||

|

|

|

|

| |||

|

|

|

|

| |||

boiler system control |

|

|

|

|

| ||

|

|

|

|

| |||

|

|

|

|

|

|

| |

On/Off Modes |

| SBC | ™ | ||||

• Performs control functions for both single and |

| ||||||

• Controls the boiler |

|

| |||||

multiple boilers |

|

|

|

|

|

| |

modulation and on/ off |

|

|

|

|

| ||

|

|

|

|

|

| ||

output based on the supply water temperature and an |

| ||||||

• Includes | operator adjusted setpoint |

|

|

|

|

| |

modulating boilers | • Can respond to remote system water, outside air |

|

| ||||

• Capable of auto rotation, outdoor reset and | temperatures, Domestic Hot Water Priority (DHWP) or |

| |||||

Energy Management Systems (EMS) |

|

|

|

| |||

• “Plug and play” communication by simply | Outdoor Air Temperature Reset |

|

|

|

| ||

connecting a RJ11 telephone line between boilers | • Saves fuel by reducing the supply temperature of a |

| |||||

• Provides precise boiler coordination by sequencing |

| ||||||

heating boiler as the outside air temperature increases |

| ||||||

boilers based on both remote system water | Warm Weather Shutdown (WWSD) |

|

|

|

| ||

temperature and boiler modulation rate. | • Prevents the boiler, boiler pump and/or the system |

| |||||

• Boilers are modulated in “unison”, all at the same | pump from starting during warm weather | |

firing rate to ensure even heat distribution | ||

Domestic Hot Water Priority (DHWP) | ||

|

Fail-Safe System Operations

•Allows continued boiler operation in the event of selected sensor failure or building management system failure

•Continuous supply of hot water, even during warmer months

System Control Outputs

•Fully integrated automation of mixing valves, boiler pumps, system pumps, and standby system pumps

•Control parameters are field selectable through simple yes/no menu selections

4