V9 Series Ratings

& equipment Listing

|

|

| neT I=B=R RATInGS (2) (3) | BURneR InpUT | neT | pReSSURe |

| ||||

|

| GROSS |

|

|

|

|

|

| FIReBOX | In FIReBOX |

|

|

|

| STeAM |

|

|

|

| ||||

BOILeR |

| OUTpUT |

| WATeR | OIL | GAS | VOLUMe | (In. WTR. | I=B=R VenT | ||

|

|

|

| ||||||||

MODeL (1) | BOILeR H.p. | MBH (2) | MBH |

| SQ. FT. | MBH | (GpH) (4) | (MBH) | (CU. FT) | COLUMn) | DIA. (In.) |

|

|

|

|

|

|

|

|

|

|

|

|

10.3 | 347 | 260 |

| 1083 | 302 | 3.1 | 447 | 3.2 | .33 | 7 | |

14.4 | 483 | 362 |

| 1508 | 420 | 4.2 | 606 | 4.8 | .38 | 7 | |

19.3 | 646 | 485 |

| 2021 | 562 | 5.6 | 808 | 6.4 | .31 | 8 | |

24.1 | 808 | 606 |

| 2525 | 703 | 7.0 | 1010 | 7.9 | .38 | 8 | |

28.6 | 959 | 719 |

| 2996 | 834 | 8.3 | 1198 | 9.5 | .36 | 8 | |

33.2 | 1110 | 833 |

| 3471 | 965 | 9.6 | 1386 | 11.0 | .35 | 10 | |

40.1 | 1342 | 1014 |

| 4225 | 1167 | 11.6 | 1674 | 12.6 | .35 | 10 | |

45.6 | 1528 | 1168 |

| 4867 | 1329 | 13.2 | 1905 | 14.2 | .40 | 10 | |

51.2 | 1714 | 1323 |

| 5513 | 1490 | 14.8 | 2136 | 15.7 | .45 | 12 | |

56.8 | 1900 | 1474 |

| 6142 | 1652 | 16.4 | 2367 | 17.3 | .49 | 12 | |

|

|

|

|

|

|

|

|

|

|

|

|

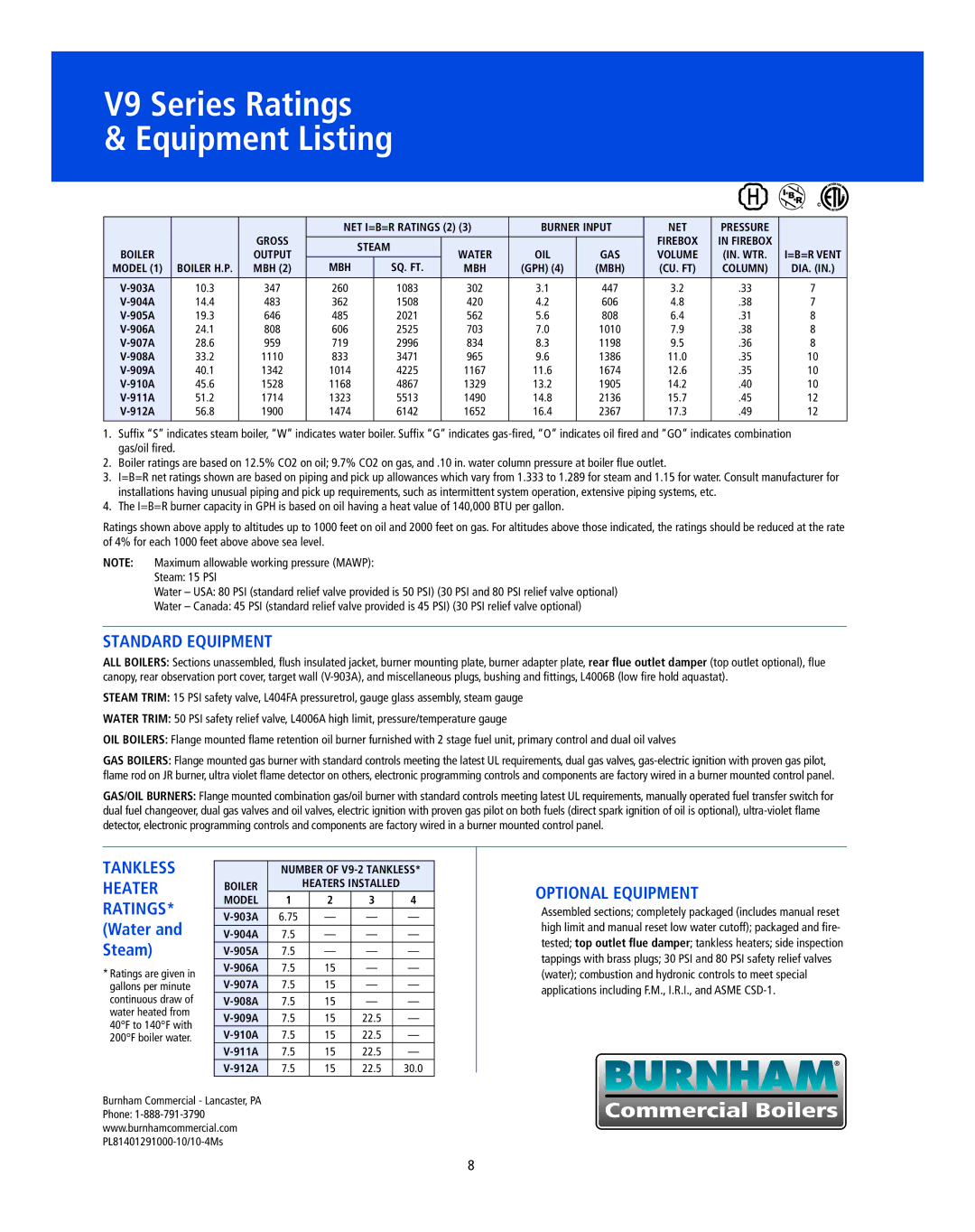

1.Suffix “S” indicates steam boiler, “W” indicates water boiler. Suffix “G” indicates

2.Boiler ratings are based on 12.5% CO2 on oil; 9.7% CO2 on gas, and .10 in. water column pressure at boiler flue outlet.

3.I=B=R net ratings shown are based on piping and pick up allowances which vary from 1.333 to 1.289 for steam and 1.15 for water. Consult manufacturer for installations having unusual piping and pick up requirements, such as intermittent system operation, extensive piping systems, etc.

4.The I=B=R burner capacity in GPH is based on oil having a heat value of 140,000 BTU per gallon.

Ratings shown above apply to altitudes up to 1000 feet on oil and 2000 feet on gas. For altitudes above those indicated, the ratings should be reduced at the rate of 4% for each 1000 feet above above sea level.

nOTe: Maximum allowable working pressure (MAWP): Steam: 15 PSI

Water – USA: 80 PSI (standard relief valve provided is 50 PSI) (30 PSI and 80 PSI relief valve optional)

Water – Canada: 45 PSI (standard relief valve provided is 45 PSI) (30 PSI relief valve optional)

STAnDARD eQUIpMenT

ALL BOILeRS: Sections unassembled, flush insulated jacket, burner mounting plate, burner adapter plate, rear flue outlet damper (top outlet optional), flue canopy, rear observation port cover, target wall

STeAM TRIM: 15 PSI safety valve, L404FA pressuretrol, gauge glass assembly, steam gauge

WATeR TRIM: 50 PSI safety relief valve, L4006A high limit, pressure/temperature gauge

OIL BOILeRS: Flange mounted flame retention oil burner furnished with 2 stage fuel unit, primary control and dual oil valves

GAS BOILeRS: Flange mounted gas burner with standard controls meeting the latest UL requirements, dual gas valves,

GAS/OIL BURneRS: Flange mounted combination gas/oil burner with standard controls meeting latest UL requirements, manually operated fuel transfer switch for dual fuel changeover, dual gas valves and oil valves, electric ignition with proven gas pilot on both fuels (direct spark ignition of oil is optional),

TAnKLeSS HeATeR RATInGS* (Water and Steam)

*Ratings are given in gallons per minute continuous draw of water heated from

40°F to 140°F with 200°F boiler water.

| nUMBeR OF | |||||

BOILeR |

| HeATeRS InSTALLeD |

| |||

MODeL | 1 |

| 2 | 3 |

| 4 |

6.75 |

| Ñ | Ñ |

| Ñ | |

7.5 |

| Ñ | Ñ |

| Ñ | |

7.5 |

| Ñ | Ñ |

| Ñ | |

7.5 |

| 15 | Ñ |

| Ñ | |

7.5 |

| 15 | Ñ |

| Ñ | |

7.5 |

| 15 | Ñ |

| Ñ | |

7.5 |

| 15 | 22.5 |

| Ñ | |

7.5 |

| 15 | 22.5 |

| Ñ | |

7.5 |

| 15 | 22.5 |

| Ñ | |

7.5 |

| 15 | 22.5 |

| 30.0 | |

OpTIOnAL eQUIpMenT

Assembled sections; completely packaged (includes manual reset high limit and manual reset low water cutoff); packaged and fire- tested; top outlet flue damper; tankless heaters; side inspection

tappings with brass plugs; 30 PSI and 80 PSI safety relief valves

(water); combustion and hydronic controls to meet special

applications including F.M., I.R.I., and ASME

Burnham Commercial - Lancaster, PA

Phone:

www.burnhamcommercial.com

8