turning blades. If clutch does not slip, contact your authorized Bush Hog dealer.

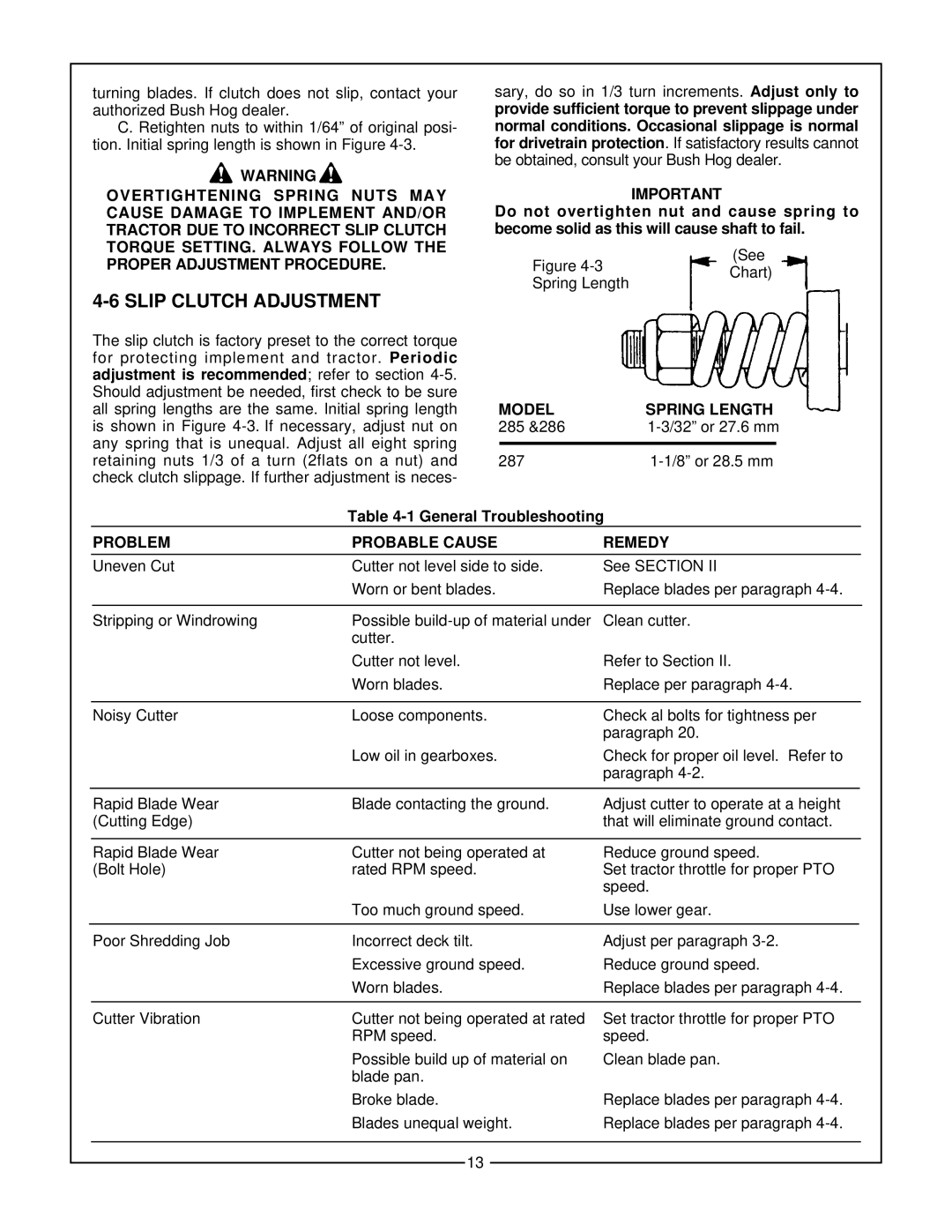

C. Retighten nuts to within 1/64” of original posi- tion. Initial spring length is shown in Figure

![]() WARNING

WARNING ![]()

OVERTIGHTENING SPRING NUTS MAY CAUSE DAMAGE TO IMPLEMENT AND/OR TRACTOR DUE TO INCORRECT SLIP CLUTCH TORQUE SETTING. ALWAYS FOLLOW THE PROPER ADJUSTMENT PROCEDURE.

4-6 SLIP CLUTCH ADJUSTMENT

The slip clutch is factory preset to the correct torque for protecting implement and tractor. Periodic adjustment is recommended; refer to section

sary, do so in 1/3 turn increments. Adjust only to provide sufficient torque to prevent slippage under normal conditions. Occasional slippage is normal for drivetrain protection. If satisfactory results cannot be obtained, consult your Bush Hog dealer.

IMPORTANT

Do not overtighten nut and cause spring to become solid as this will cause shaft to fail.

(See

Figure 4-3 Chart) Spring Length

| MODEL | SPRING LENGTH | |

285 &286 | |||

|

|

|

|

287 | |||

|

|

|

|

Table

| PROBLEM | PROBABLE CAUSE | REMEDY | |

| Uneven Cut | Cutter not level side to side. | See SECTION II | |

|

| Worn or bent blades. | Replace blades per paragraph | |

|

|

|

|

|

| Stripping or Windrowing | Possible | Clean cutter. | |

|

| cutter. |

|

|

|

| Cutter not level. | Refer to Section II. | |

|

| Worn blades. | Replace per paragraph | |

|

|

|

|

|

| Noisy Cutter | Loose components. | Check al bolts for tightness per | |

|

|

| paragraph 20. | |

|

| Low oil in gearboxes. | Check for proper oil level. Refer to | |

|

|

| paragraph | |

|

|

|

|

|

| Rapid Blade Wear | Blade contacting the ground. | Adjust cutter to operate at a height | |

| (Cutting Edge) |

| that will eliminate ground contact. | |

|

|

|

|

|

| Rapid Blade Wear | Cutter not being operated at | Reduce ground speed. | |

| (Bolt Hole) | rated RPM speed. | Set tractor throttle for proper PTO | |

|

|

| speed. | |

|

| Too much ground speed. | Use lower gear. | |

|

|

|

|

|

| Poor Shredding Job | Incorrect deck tilt. | Adjust per paragraph | |

|

| Excessive ground speed. | Reduce ground speed. | |

|

| Worn blades. | Replace blades per paragraph | |

|

|

|

| |

| Cutter Vibration | Cutter not being operated at rated | Set tractor throttle for proper PTO | |

|

| RPM speed. | speed. | |

|

| Possible build up of material on | Clean blade pan. | |

|

| blade pan. |

|

|

|

| Broke blade. | Replace blades per paragraph | |

|

| Blades unequal weight. | Replace blades per paragraph | |

|

|

|

|

|

13