|

|

|

|

|

|

|

|

|

|

|

| SECTION IV |

|

|

|

| |||

|

| MAINTENANCE |

|

|

|

| |||

|

|

|

| 8.During operation, listen for abnormal sounds |

| ||||

|

|

| |||||||

|

| which might indicate loose parts, damaged bearings, |

| ||||||

| Perform scheduled maintenance as outlined below. |

| or other damage. Correct any deficiency before con- |

| |||||

| Lower implement to ground, turn off tractor, and set |

| tinuing operation. |

|

|

|

| ||

| parking brake before doing maintenance inspections |

|

|

|

|

| |||

| or work. Some checks may require raising machine |

|

| AFTER EACH USE |

| ||||

| off ground and supporting with blocks. All bolts |

| 1. Clean all debris from machine especially under- |

| |||||

| should be torqued as indicated in torque chart on |

| side of deck, underneath belt shield and off safety |

| |||||

| page 16 unless otherwise indicated. |

| decals. Replace any missing or illegible decals. |

| |||||

|

|

|

| 2. Inspect cutter for worn or damaged compo- |

| ||||

|

|

| |||||||

|

| WARNING |

| nents. Repair or replace before next use. Any |

| ||||

| THE CUTTER CAN FALL FROM |

| replacement components installed during repair shall |

| |||||

| HYDRAULIC SYSTEM FAILURE. TO |

| include the components’ current safety decals speci- |

| |||||

| AVOID SERIOUS INJURY OR DEATH, |

| fied by the manufacturer to be affixed to the compo- |

|

| ||||

| SECURELY SUPPORT CUTTER BEFORE |

| nent. |

|

|

|

| ||

| WORKING UNDERNEATH. |

| 3. Store cutter in a dry place. |

| |||||

|

|

|

|

|

| 40 HOURS |

| ||

|

| BEFORE EACH USE. |

| 1. Check belt for proper tension. Refer to para- |

| ||||

| 1. Check tractor tire air pressure. Refer to |

| graph |

|

|

|

| ||

| tractor operator’s manual. Check mower tire pres- |

|

|

|

| ||||

| sure. Tire pressure should be 40 psi. |

|

| ||||||

| 2. Check blades and spindles to be sure that no |

|

|

| NOTE |

|

|

| |

| foreign objects such as wire or steel strapping bands |

|

| The |

|

| |||

| are wrapped around them. |

|

| secftion is an NLGI Grade 2 type grease. |

|

|

| ||

| 3. Check blade bolts for tightness. Tighten to 76 |

|

|

|

| ||||

| ft./lbs. |

|

| BEFORE EACH USE |

| ||||

| 4. Inspect blades for wear. Replace if necessary |

| 1. Driveline Universal Joints - Apply |

| |||||

| per paragraph |

| pose grease with grease gun. |

| |||||

| replacement parts. If it is necessary to sharpen the |

| 2. Driveline Guard - Apply |

| |||||

| blades, remove the blades from the spindles before |

| pose grease with grease gun to plastic fitting. |

| |||||

| sharpening. DO NOT sharpen blades while still |

| 3. Wheels - Apply |

| |||||

| attached to mower. |

| grease gun. |

|

|

|

| ||

| 5. Make certain all shields are in place and in |

| 4. Caster Pivot - Apply |

| |||||

| good condition. Repair or replace any missing or |

| grease gun. |

|

|

|

| ||

| damaged shields. |

| 5. Input Gearbox - Add |

| |||||

| 6. Inspect wheel(s) for wear, damage or foreign |

| necessary, to bring oil level to check plug. |

|

| ||||

| objects. Repair or replace if necessary. |

|

| ||||||

| 7. Perform BEFORE EACH USE lubrication per |

|

|

| 20 HOURS |

| |||

| paragraph |

| 6. Driveline - Disconnect PTO driveline, pull the |

| |||||

|

|

|

| two sections apart, apply thin coat of |

| ||||

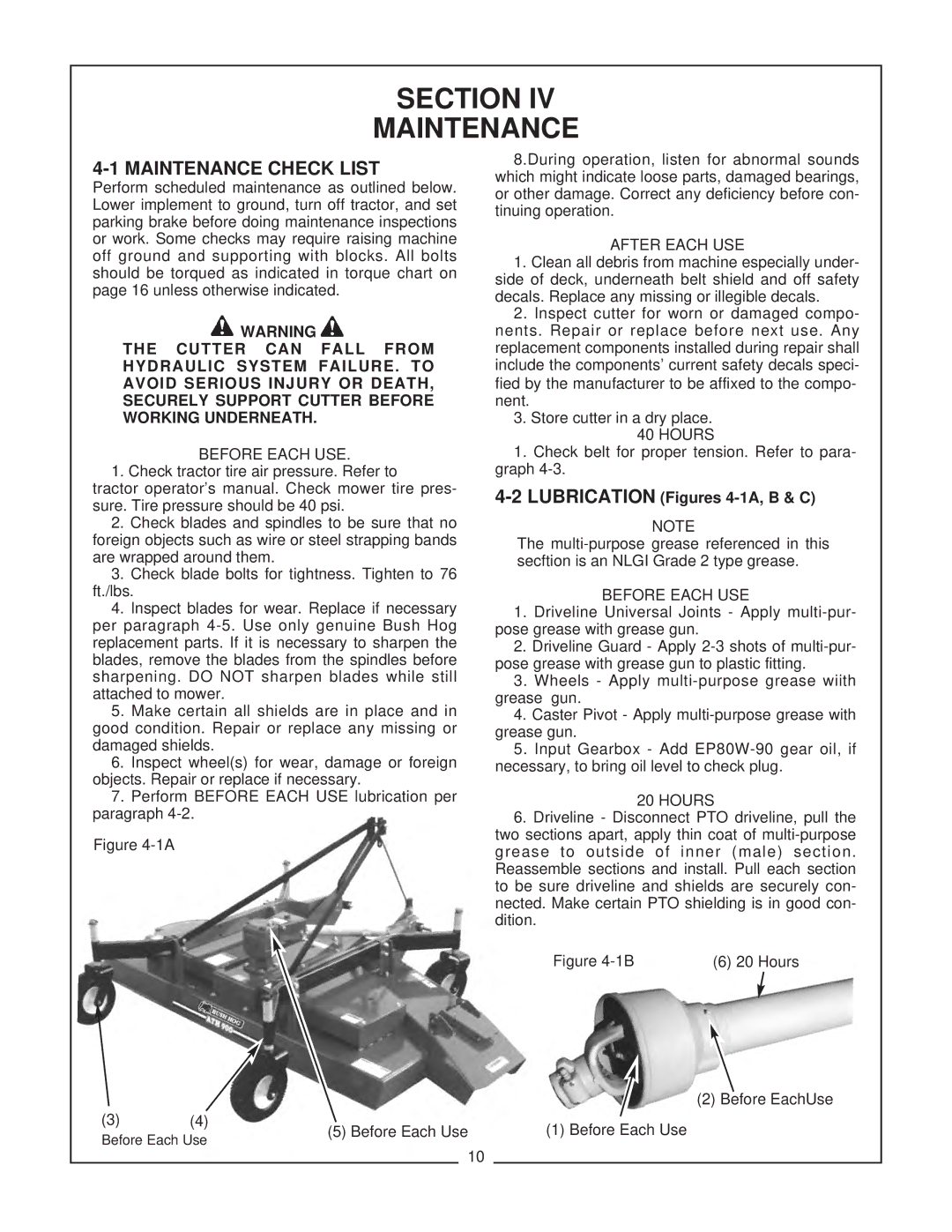

| Figure |

|

| ||||||

|

|

| grease to outside of inner (male) section. |

| |||||

|

|

|

| Reassemble sections and install. Pull each section |

| ||||

|

|

|

| ||||||

|

|

|

| to be sure driveline and shields are securely con- |

| ||||

|

|

|

| nected. Make certain PTO shielding is in good con- |

| ||||

|

|

|

| dition. |

|

|

|

| |

|

|

|

|

| Figure | (6) 20 Hours |

|

| |

(3) |

| (4) |

|

|

|

|

|

| (2) Before EachUse |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

| (1) Before Each Use |

| ||

|

| (5) Before Each Use |

|

|

| ||||

Before Each | Use |

|

|

|

| ||||

|

|

|

| ||||||

|

| 10 | |||||||

|

|

|

|

|

|

| |||