Operating Instructions and Parts Manual | AL2810 |

Airless Paint Systems

General Safety Information (Cont.)

● Paints and solvents containing |

HALOGENATED HYDROCARBONS can |

react explosively with aluminum. Do |

not use halogenated hydrocarbons |

with this equipment. Consult the |

paint or solvent product label or |

Material Safety Data Sheets (MSDS) |

to help determine if it contains |

halogenated hydrocarbons. |

● Do not use fuels to clean this |

equipment. |

3.CHANGING FROM

4.CHANGING FROM

5.STORAGE: Always relieve pressure (See pressure relief procedure on page 3) prior to storage or when machine is unattended. Follow the storage procedure based on the kind of paint you used:

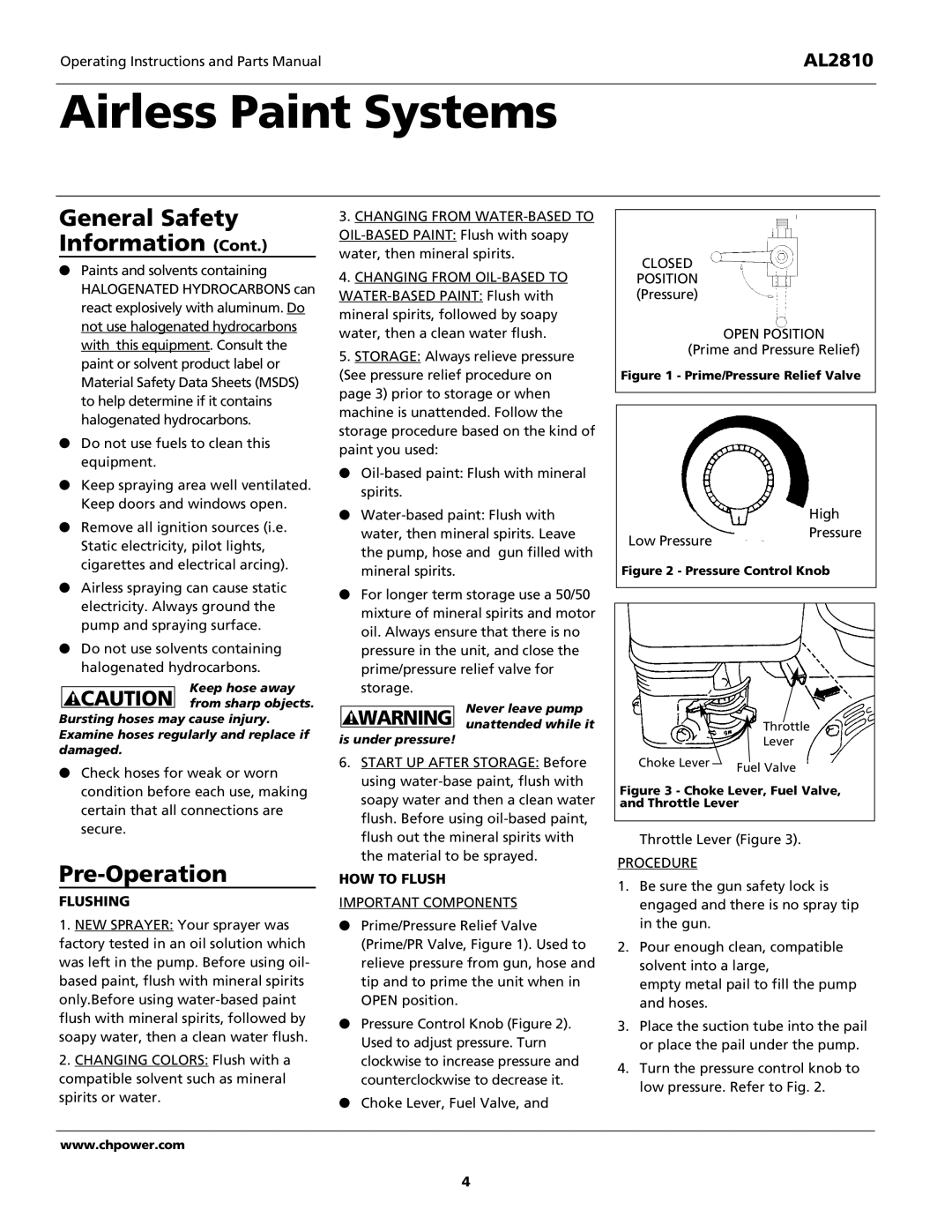

CLOSED

POSITION (Pressure)

OPEN POSITION

(Prime and Pressure Relief)

Figure 1 - Prime/Pressure Relief Valve

● Keep spraying area well ventilated. |

Keep doors and windows open. |

● Remove all ignition sources (i.e. |

Static electricity, pilot lights, |

cigarettes and electrical arcing). |

● |

spirits. |

● |

water, then mineral spirits. Leave |

the pump, hose and gun filled with |

Low Pressure

High Pressure

● Airless spraying can cause static |

electricity. Always ground the |

pump and spraying surface. |

● Do not use solvents containing |

halogenated hydrocarbons. |

Keep hose away

! CAUTION from sharp objects. Bursting hoses may cause injury. Examine hoses regularly and replace if damaged.

●Check hoses for weak or worn condition before each use, making certain that all connections are secure.

Pre-Operation

FLUSHING

1.NEW SPRAYER: Your sprayer was

factory tested in an oil solution which was left in the pump. Before using oil- based paint, flush with mineral spirits only.Before using

2.CHANGING COLORS: Flush with a compatible solvent such as mineral spirits or water.

mineral spirits. |

● For longer term storage use a 50/50 |

mixture of mineral spirits and motor |

oil. Always ensure that there is no |

pressure in the unit, and close the |

prime/pressure relief valve for |

storage. |

Never leave pump

! WARNING unattended while it

is under pressure!

6. START UP AFTER STORAGE: Before using

HOW TO FLUSH

IMPORTANT COMPONENTS

●Prime/Pressure Relief Valve (Prime/PR Valve, Figure 1). Used to relieve pressure from gun, hose and tip and to prime the unit when in OPEN position.

●Pressure Control Knob (Figure 2). Used to adjust pressure. Turn clockwise to increase pressure and counterclockwise to decrease it.

●Choke Lever, Fuel Valve, and

Figure 2 - Pressure Control Knob

Throttle

Lever

Choke Lever | Fuel Valve |

|

Figure 3 - Choke Lever, Fuel Valve, and Throttle Lever

Throttle Lever (Figure 3).

PROCEDURE

1.Be sure the gun safety lock is engaged and there is no spray tip in the gun.

2.Pour enough clean, compatible solvent into a large,

empty metal pail to fill the pump and hoses.

3.Place the suction tube into the pail or place the pail under the pump.

4.Turn the pressure control knob to low pressure. Refer to Fig. 2.

www.chpower.com

4