Operating Instructions and Parts Manual | AL2810 |

Airless Paint Systems

Service

FLUID PUMP

FLUID PUMP DISCONNECT

1.Flush out the material you are spraying, if possible.

2.Follow the Pressure Relief Procedure on page 3. Stop the pump in the middle of down stroke.

3.Remove the suction tube and fluid hose (if so equipped) from the fluid pump. Detach the hose from the front of the fluid pump.

4.Remove 2 retaining rings and slip the sleeve of the coupling down and remove both coupling halves. This will disconnect fluid pump from the connecting rod.

5.Unscrew the two tie rod locknuts.

6.Pull the pump down off the tie rods.

FLUID PUMP REINSTALL

1. | Loosen packing nut and extend |

| piston rod so that it is in the “fully |

| up” position. |

2. | Make sure that spacer tubes (301- |

| 048) are in place. |

3. | Connect connecting rod with fluid |

| pump by installing coupling halves. |

| Slide sleeve over coupling halves. |

| Secure with retaining rings. |

4. | Secure the fluid pump housing to |

| the tie rods and screw nuts with |

| lock washers on loosely. |

5. | Tighten the tie rod nuts evenly to |

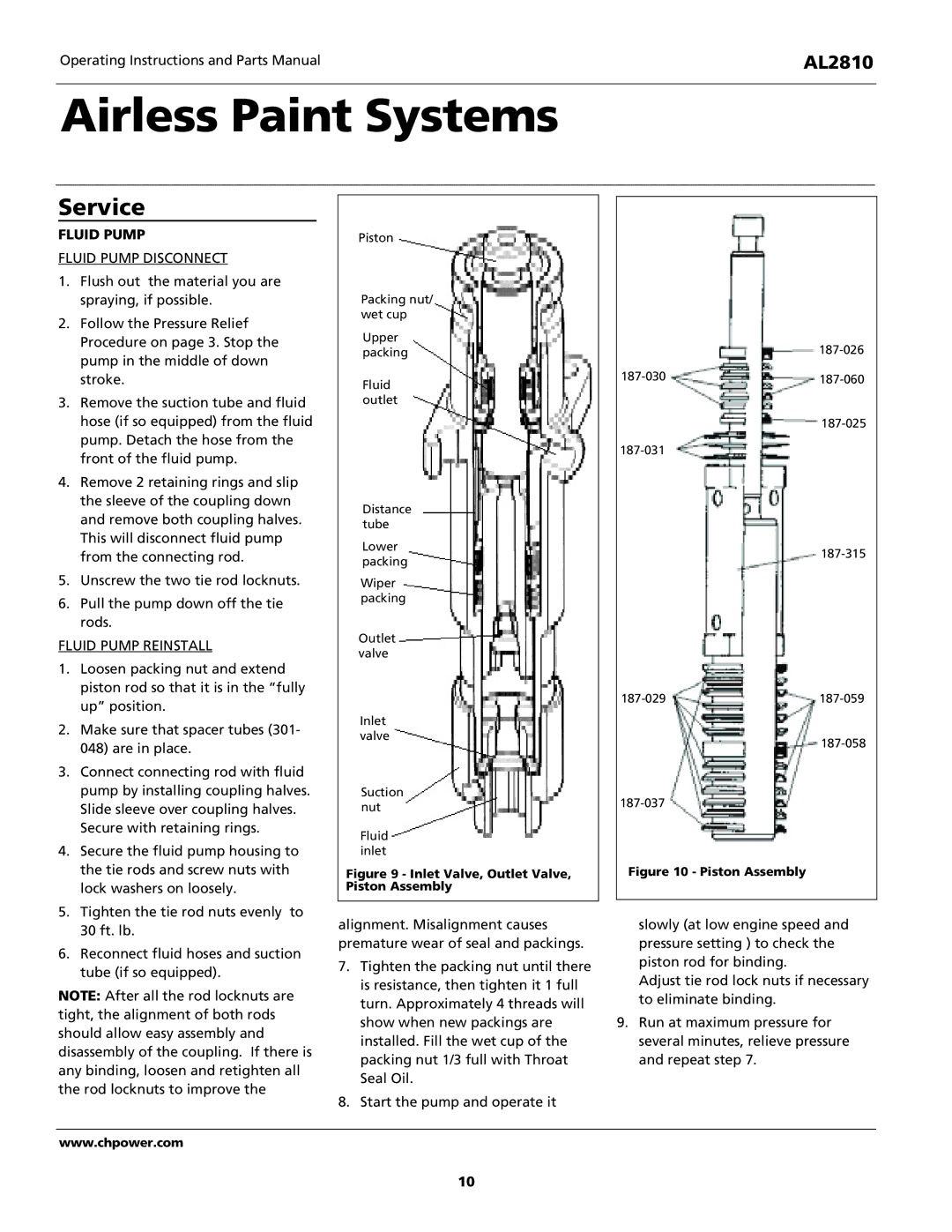

Piston

Packing nut/ wet cup

Upper packing

Fluid outlet

Distance tube

Lower packing

Wiper packing

Outlet valve

Inlet valve

Suction nut

Fluid inlet

Figure 9 - Inlet Valve, Outlet Valve, Piston Assembly

|

|

| |||

|

|

|

|

|

|

|

|

|

| ||

| |||||

|

|

|

|

| |

|

|

|

| ||

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |||

|

|

|

| |

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

Figure 10 - Piston Assembly

30 ft. lb. |

6. Reconnect fluid hoses and suction |

tube (if so equipped). |

NOTE: After all the rod locknuts are tight, the alignment of both rods should allow easy assembly and disassembly of the coupling. If there is any binding, loosen and retighten all the rod locknuts to improve the

alignment. Misalignment causes premature wear of seal and packings.

7.Tighten the packing nut until there is resistance, then tighten it 1 full turn. Approximately 4 threads will show when new packings are installed. Fill the wet cup of the packing nut 1/3 full with Throat Seal Oil.

8.Start the pump and operate it

slowly (at low engine speed and pressure setting ) to check the piston rod for binding.

Adjust tie rod lock nuts if necessary to eliminate binding.

9.Run at maximum pressure for several minutes, relieve pressure and repeat step 7.

www.chpower.com

10