Portable Air Compressors

Installation (Cont.)

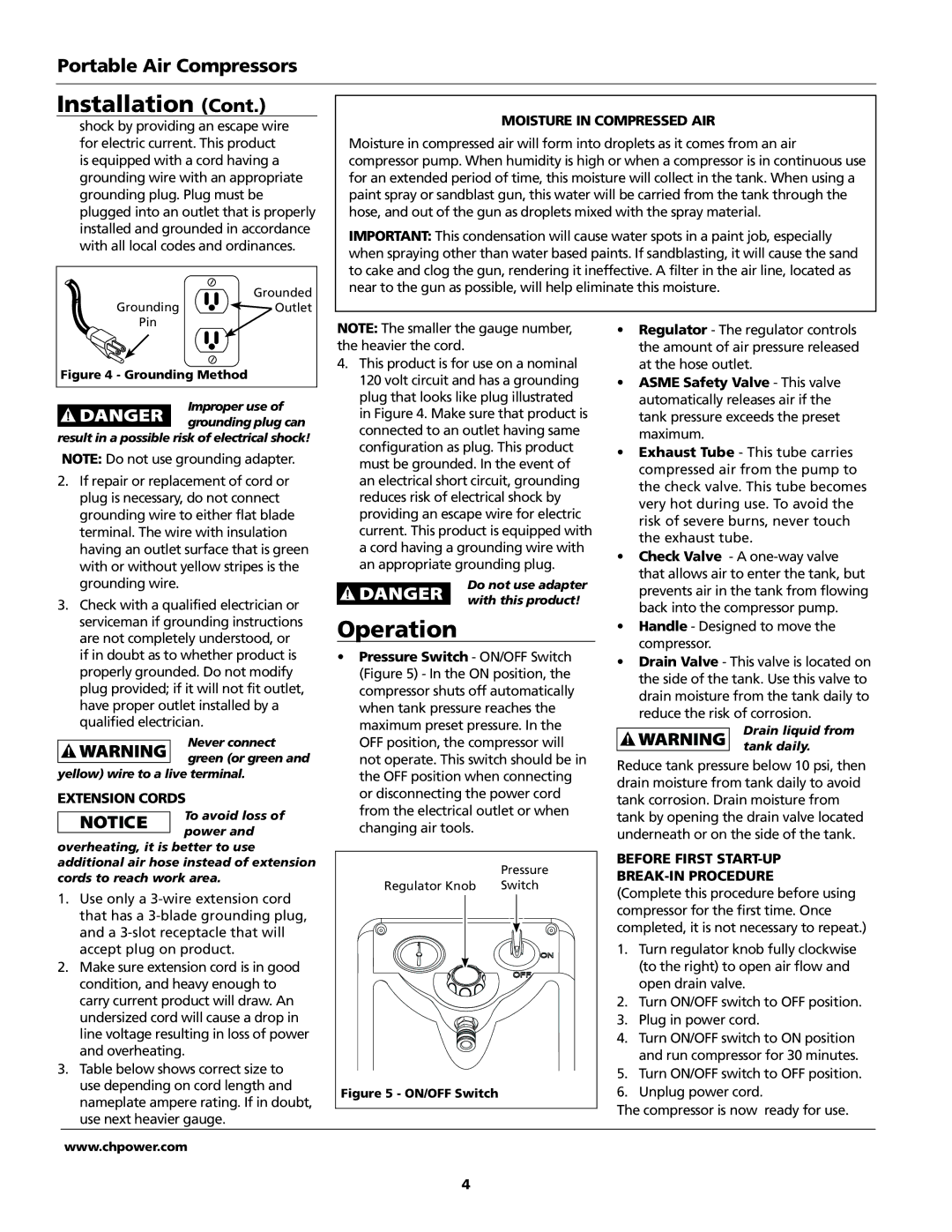

shock by providing an escape wire for electric current. This product is equipped with a cord having a grounding wire with an appropriate grounding plug. Plug must be plugged into an outlet that is properly installed and grounded in accordance with all local codes and ordinances.

Grounded

Moisture in compressed air

Moisture in compressed air will form into droplets as it comes from an air compressor pump. When humidity is high or when a compressor is in continuous use for an extended period of time, this moisture will collect in the tank. When using a paint spray or sandblast gun, this water will be carried from the tank through the hose, and out of the gun as droplets mixed with the spray material.

Important: This condensation will cause water spots in a paint job, especially when spraying other than water based paints. If sandblasting, it will cause the sand to cake and clog the gun, rendering it ineffective. A filter in the air line, located as near to the gun as possible, will help eliminate this moisture.

Grounding ![]()

![]() Outlet Pin

Outlet Pin ![]()

Figure 4 - Grounding Method

Improper use of grounding plug can

result in a possible risk of electrical shock!

NOTE: Do not use grounding adapter.

2.If repair or replacement of cord or plug is necessary, do not connect grounding wire to either flat blade terminal. The wire with insulation having an outlet surface that is green with or without yellow stripes is the grounding wire.

3.Check with a qualified electrician or serviceman if grounding instructions are not completely understood, or if in doubt as to whether product is properly grounded. Do not modify plug provided; if it will not fit outlet, have proper outlet installed by a qualified electrician.

Never connect green (or green and

yellow) wire to a live terminal.

Extension cords

To avoid loss of power and

overheating, it is better to use additional air hose instead of extension cords to reach work area.

1.Use only a

2.Make sure extension cord is in good condition, and heavy enough to carry current product will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating.

3.Table below shows correct size to use depending on cord length and nameplate ampere rating. If in doubt, use next heavier gauge.

NOTE: The smaller the gauge number, the heavier the cord.

4.This product is for use on a nominal 120 volt circuit and has a grounding plug that looks like plug illustrated in Figure 4. Make sure that product is connected to an outlet having same configuration as plug. This product must be grounded. In the event of an electrical short circuit, grounding reduces risk of electrical shock by providing an escape wire for electric current. This product is equipped with a cord having a grounding wire with an appropriate grounding plug.

Do not use adapter with this product!

Operation

•Pressure Switch - ON/Off Switch (Figure 5) - In the ON position, the compressor shuts off automatically when tank pressure reaches the maximum preset pressure. In the Off position, the compressor will not operate. This switch should be in the Off position when connecting or disconnecting the power cord from the electrical outlet or when changing air tools.

|

|

|

|

| Pressure | |||||||||

Regulator Knob |

| Switch | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure 5 - ON/OFF Switch

•Regulator - The regulator controls the amount of air pressure released at the hose outlet.

•ASME Safety Valve - This valve automatically releases air if the tank pressure exceeds the preset maximum.

•Exhaust Tube - This tube carries compressed air from the pump to the check valve. This tube becomes very hot during use. To avoid the risk of severe burns, never touch the exhaust tube.

•Check Valve - A

•Handle - Designed to move the compressor.

•Drain Valve - This valve is located on the side of the tank. Use this valve to drain moisture from the tank daily to reduce the risk of corrosion.

Drain liquid from tank daily.

Reduce tank pressure below 10 psi, then drain moisture from tank daily to avoid tank corrosion. Drain moisture from tank by opening the drain valve located underneath or on the side of the tank.

Before first

1.Turn regulator knob fully clockwise (to the right) to open air flow and open drain valve.

2.Turn On/Off switch to OFF position.

3.Plug in power cord.

4.Turn On/Off switch to ON position and run compressor for 30 minutes.

5.Turn On/Off switch to OFF position.

6.Unplug power cord.

The compressor is now ready for use.

www.chpower.com