Operating Instructions and Parts Manual | IFT232 |

Manuel de Instrucciones y Lista de Piezas | IFT232 |

Air Tool Set-Up

PLEASE REFER TO RECOMMENDED AIR TOOL

NOTE: Do not use lubricator, Part No. PA2081, as shown in the

RECOMMENDED AIR TOOL

For proper performance and more con- venience, use a 3/8" I.D. hose. Hoses longer than 50 feet should have a 1/2" I.D.

Figure 1 |

Spray Operation

Do not misuse this

!WARNING product. Excessive exposure to vibration, work in awk- ward positions and repetitive work motions can cause injury to hands and arms. Stop using any tool if discomfort, numbness, tingling or pain occur, and consult a physician.

1.Connect the solution hose to the barb fitting.

2.Connect sprayer to air supply.

3.Place material strainer end of hose into the solution being sprayed and clamp the hose to the edge of the container without crushing the tub- ing.

Figure 2

4.Pull the trigger and allow approxi- mately 5 seconds for the solution to reach the spray nozzle. Release the trigger to stop the flow.

5.Adjust the pressure regulator to start at 20 psi and increase until desired spray volume and atomiza- tion is achieved, usually between 20 - 30 psi.

Do not exceed the

!WARNING maximum operating pressure of the sprayer (90 psi).

Figure 3 |

(Extended) Blow Gun Operation

1.(Optional) Thread the extension to the air blow gun.

2.(Optional) Thread the rubber tip to the end of the extension or the blow gun.

3.Connect to the air supply.

Do not exceed the

!WARNING maximum operating pressure of the blow gun (90 psi).

Safety glasses

! WARNING must be worn dur- ing operation.

Never aim or spray ! WARNING at yourself or any-

one else or serious injury could occur. Always wear eye protection.

4. Pull the trigger and check to make sure the desired air flow is achieved (adjust the pressure regulator to achieve the desired flow).

STORAGE

The sprayer must be thoroughly flushed and cleaned before storing. Refer to the manufactures instructions for the liquid being sprayed.

TECHNICAL SERVICE

For information regarding the opera- tion or repair of this product, please call

Para Ordenar Repuestos, Sírvase Llamar al Distribuidor de Campbell Hausfeld más Cercano a su Domicilio

Sírvase darnos la siguiente información:

-Número del modelo

-Número de Serie o código con fecha (de haberlo)

-Descripción y número del repuesto según la lista de repuestos

Puede escribirnos a: The Campbell Group Attn: Parts Department 100 Production Drive Harrison, OH 45030 U.S.A.

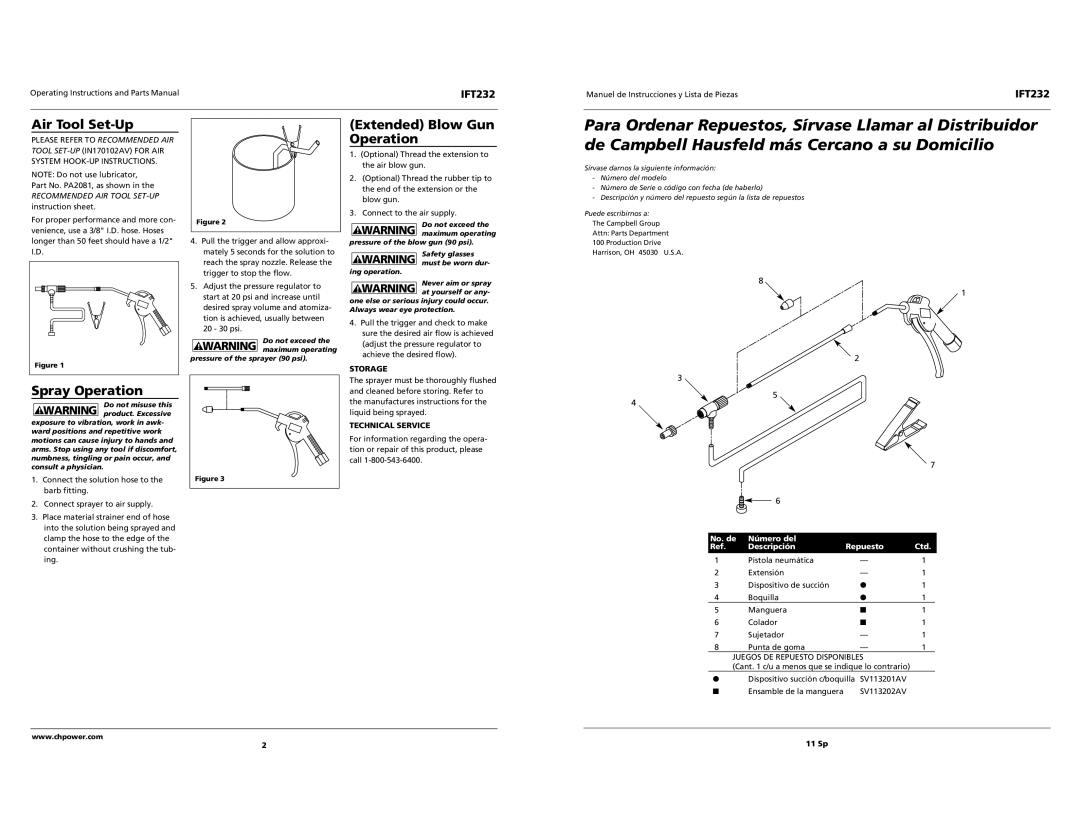

8

1

2

3

5

4

|

|

|

|

| 7 | |

|

|

| 6 |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

No. de | Número del |

|

|

| ||

Ref. | Descripción | Repuesto | Ctd. | |||

1 | Pistola neumática | — | 1 |

| ||

2 | Extensión | — | 1 |

| ||

3 | Dispositivo de succión | ● | 1 |

| ||

4 | Boquilla | ● | 1 |

| ||

5 | Manguera | ■ | 1 |

| ||

6 | Colador | ■ | 1 |

| ||

7 | Sujetador | — | 1 |

| ||

8 | Punta de goma | — | 1 |

| ||

JUEGOS DE REPUESTO DISPONIBLES

(Cant. 1 c/u a menos que se indique lo contrario)

●Dispositivo succión c/boquilla SV113201AV

■ | Ensamble de la manguera | SV113202AV |

www.chpower.com

2 | 11 Sp |