Operating Instructions

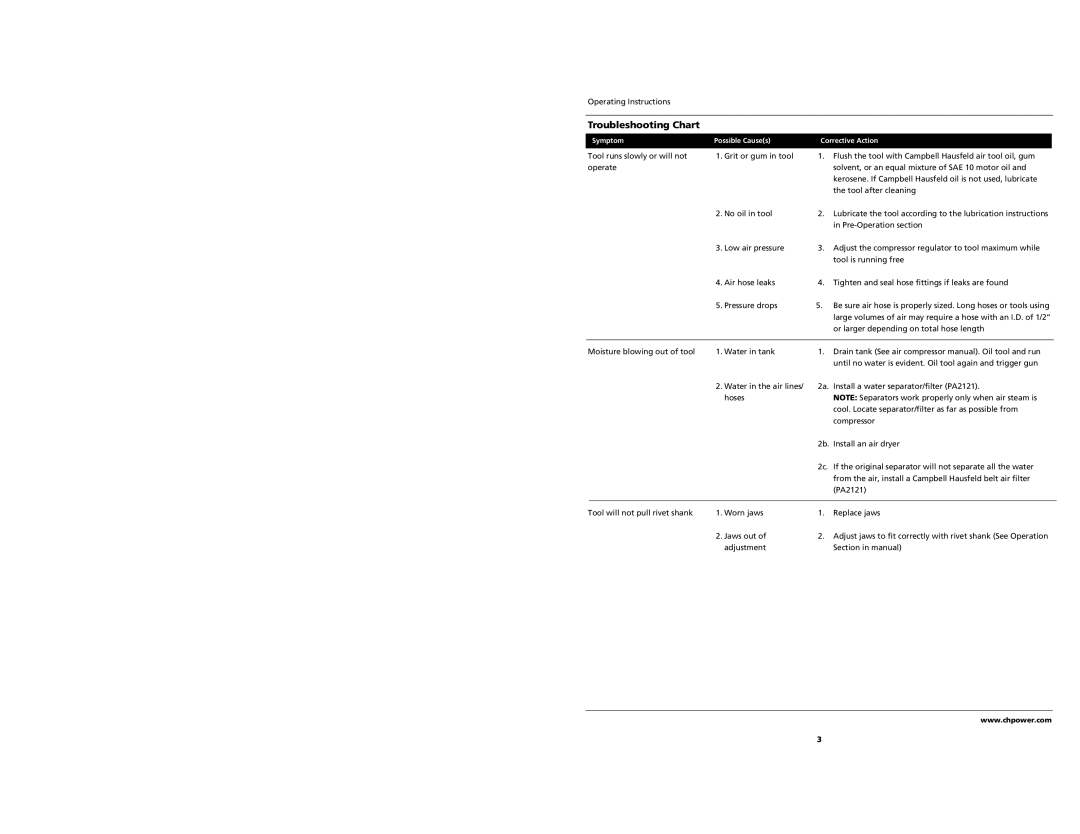

Troubleshooting Chart

| Symptom | Possible Cause(s) | Corrective Action |

|

| |

Tool runs slowly or will not | 1. Grit or gum in tool | 1. | Flush the tool with Campbell Hausfeld air tool oil, gum |

|

| |

operate |

|

| solvent, or an equal mixture of SAE 10 motor oil and |

|

| |

|

|

|

| kerosene. If Campbell Hausfeld oil is not used, lubricate |

|

|

|

|

|

| the tool after cleaning |

|

|

|

| 2. No oil in tool | 2. | Lubricate the tool according to the lubrication instructions |

|

|

|

|

|

| in |

|

|

|

| 3. Low air pressure | 3. | Adjust the compressor regulator to tool maximum while |

|

|

|

|

|

| tool is running free |

|

|

|

| 4. Air hose leaks | 4. | Tighten and seal hose fittings if leaks are found |

|

|

|

| 5. Pressure drops | 5. | Be sure air hose is properly sized. Long hoses or tools using |

|

|

|

|

|

| large volumes of air may require a hose with an I.D. of 1/2” |

|

|

|

|

|

| or larger depending on total hose length |

|

|

|

|

|

|

|

|

|

Moisture blowing out of tool | 1. Water in tank | 1. | Drain tank (See air compressor manual). Oil tool and run |

|

| |

|

|

|

| until no water is evident. Oil tool again and trigger gun |

|

|

|

| 2. Water in the air lines/ | 2a. | Install a water separator/filter (PA2121). |

|

|

|

| hoses |

| NOTE: Separators work properly only when air steam is |

|

|

|

|

|

| cool. Locate separator/filter as far as possible from |

|

|

|

|

|

| compressor |

|

|

|

|

| 2b. | Install an air dryer |

|

|

|

|

| 2c. | If the original separator will not separate all the water |

|

|

|

|

|

| from the air, install a Campbell Hausfeld belt air filter |

|

|

|

|

|

| (PA2121) |

|

|

|

|

|

|

|

|

|

Tool will not pull rivet shank | 1. Worn jaws | 1. | Replace jaws |

|

| |

|

| 2. Jaws out of | 2. | Adjust jaws to fit correctly with rivet shank (See Operation |

|

|

|

| adjustment |

| Section in manual) |

|

|

www.chpower.com

3