Operating Instructions | Model SB3232 |

General Safety Information (Continued)

●Always assume the tool contains fasteners. Respect the tool as a working implement; no horseplay. Always keep others at a safe dis- tance from the work area in case of accidental discharge of fasteners. Do not point the tool toward your- self or anyone whether it contains fasteners or not. Accidental trigger- ing of the tool could result in death or serious personal injury.

●Do not drive a fas-

tener on top of other fasteners. The fastener could glance and cause death or a serious puncture wound.

●Do not operate

or allow anyone

else to operate ![]()

![]() the tool if any

the tool if any ![]()

![]() warnings or

warnings or ![]()

![]() warning labels

warning labels ![]()

![]() are not legible. Warnings or warning labels are located on the tool maga- zine and body.

are not legible. Warnings or warning labels are located on the tool maga- zine and body.

●Do not drop or throw the tool. Dropping or throwing the tool can result in damage that will make the tool unusable or unsafe. If the tool has been dropped or thrown, exam- ine the tool closely for bent, cracked or broken parts and air leaks. STOP and repair before using or serious injury could occur.

Caution indicates ! CAUTION a potentially haz-

ardous situation which, if not avoided, MAY result in minor or moderate injury.

●Do not make any modifications to the tool without first obtaining written

approval from Campbell Hausfeld. Do not use the tool if any shields or guards are removed or altered. Do not use the tool as a hammer. Personal injury or tool

damage may occur.

●Avoid long extended periods of work with the tool. Stop using the tool if you feel pain in hands or arms.

●Always check that the Work Contact Element (WCE)

is operating properly. A fas-

tener could acci- dentally be dri- ven if the WCE is not working

properly. Personal injury

may occur (See "Checking the Work Contact Element" Section).

●Disconnect air supply and release tension from the pusher before attempting to clear jams because tools can be ejected from the front of the tool. Personal injury may occur.

NOTICE | Notice indicates |

important infor- |

mation, that if not followed, MAY cause damage to equipment.

●Avoid using the tool when the mag- azine is empty. Accelerated wear on the tool may occur.

●Clean and check all air supply hoses and fittings before connecting the tool to an air supply. Replace any damaged or worn hoses or fittings. Tool performance or durability may be reduced.

●Air compressors providing air to the tool should follow the requirements established by the American National Standards Institute

Standard

Operating The Tool

LUBRICATION

This tool requires lubrication before using the tool for the first time and before each use. If an inline oiler is used, manual lubrication through the air inlet is not required on a daily basis.

NOTICE | The work surface | |

can become dam- | ||

|

aged by excessive lubrication. Proper lubrication is the owner’s responsibil- ity. Failure to lubricate the tool proper- ly will dramatically shorten the life of the tool and void the warranty.

1. Disconnect the air supply from the tool to add lubricant.

2.Turn the tool so the

air inlet is facing up. OIL

Place

oil additives, or air tool oils. Air tool oils contain solvents which will dam- age the tool's internal components.

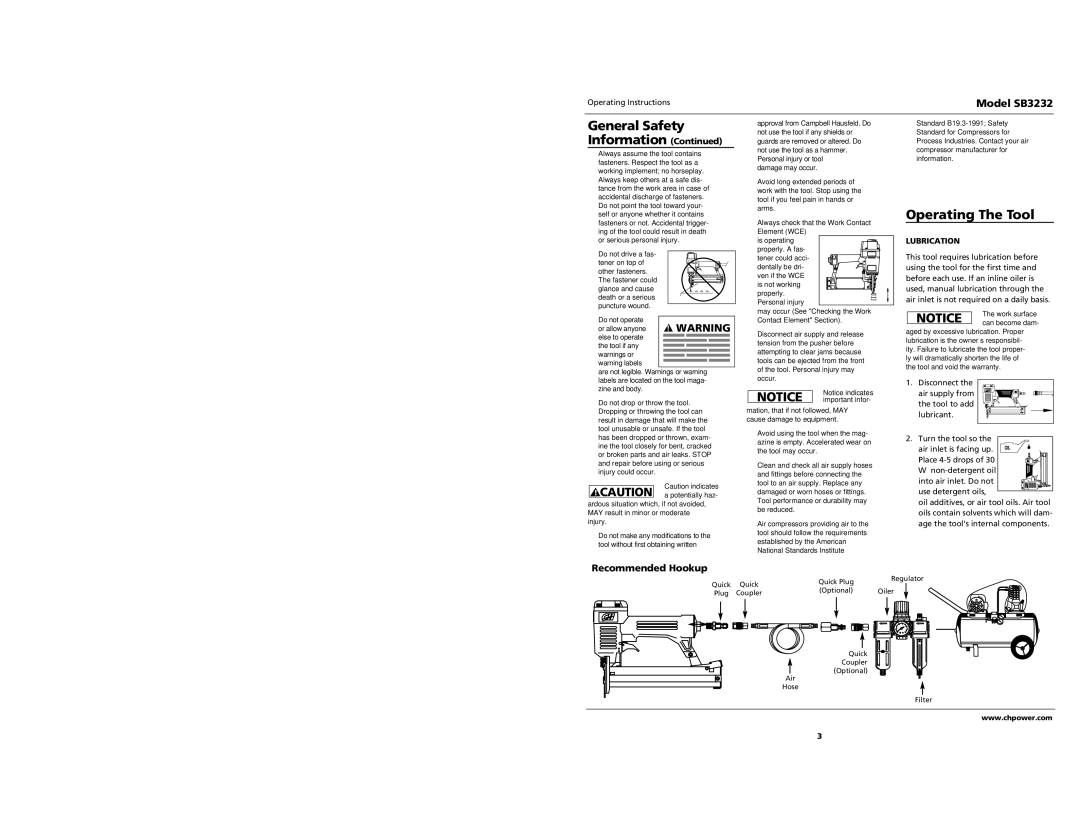

Recommended Hookup

Quick | Quick |

|

|

| Quick Plug |

|

|

|

|

|

| Regulator | ||||||||||||||||||

|

|

| (Optional) |

|

|

|

| Oiler |

|

|

|

|

| |||||||||||||||||

| Plug | Coupler |

|

|

|

|

|

|

|

|

| |||||||||||||||||||

|

|

|

|

|

|

|

|

| ||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Quick

Coupler

(Optional)

Air

Hose

Filter

www.chpower.com

3