Operating Instructions | Model SB3232 |

Operating The Tool

(Continued)

5.Always unload all fasteners before removing tool from service. Unloading is the reverse of loading, except always disconnect the air supply before unloading.

ADJUSTING THE FASTENER PENETRA- TION

1.Regulate the air pressure to 60 psi at the tool.

2.Connect the air

supply and test for penetration by driving fasteners into a sample piece of wood. If the fasteners do not achieve the desired penetration, adjust the air pressure to a higher setting until the desired penetration is achieved. Do not exceed 100 psi at the tool or durability of the tool will be reduced.

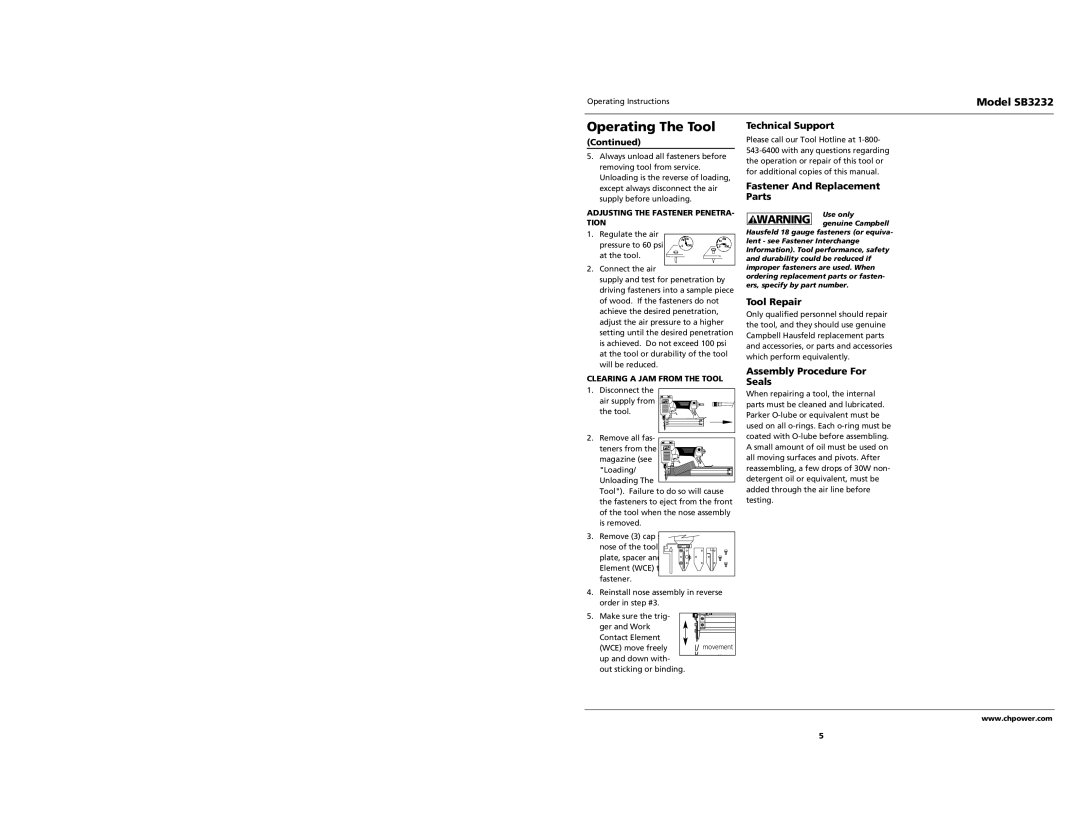

CLEARING A JAM FROM THE TOOL

1.Disconnect the air supply from

the tool.

2.Remove all fas- teners from the

magazine (see "Loading/ Unloading The

Tool"). Failure to do so will cause the fasteners to eject from the front of the tool when the nose assembly is removed.

3.Remove (3) cap nose of the tool plate, spacer and Element (WCE) fastener.

4.Reinstall nose assembly in reverse order in step #3.

5. Make sure the trig- |

|

ger and Work |

|

Contact Element |

|

(WCE) move freely | movement |

up and down with- |

|

out sticking or binding. |

|

Technical Support

Please call our Tool Hotline at

Fastener And Replacement Parts

Use only

! WARNING genuine Campbell Hausfeld 18 gauge fasteners (or equiva- lent - see Fastener Interchange Information). Tool performance, safety and durability could be reduced if improper fasteners are used. When ordering replacement parts or fasten- ers, specify by part number.

Tool Repair

Only qualified personnel should repair the tool, and they should use genuine Campbell Hausfeld replacement parts and accessories, or parts and accessories which perform equivalently.

Assembly Procedure For Seals

When repairing a tool, the internal parts must be cleaned and lubricated. Parker

www.chpower.com

5