Wire Feed Arc Welder

Figure 3 - Ground Clamp Assembly

Flux Core Wire Installation

Welding power is applied to the

output terminals, feed roll, ground clamp, gun cable connection and welding wire even when the gun switch is not activated. Do not touch these parts when the welding machine is on.

NOTE: Before installing welding wire, be sure that the diameter of the welding wire matches the contact tip in the end of the gun. The wire size is marked on the contact tip in inches or

from the spool. Do not allow the wire to unravel. Be sure that the end of the wire is straight and free of burrs.

6.Feed the wire through the wire feed guide tube, over the groove in the drive roll and into the gun liner. Tighten the wire feed tensioning screw so that it is snug. Do not over tighten.

![]()

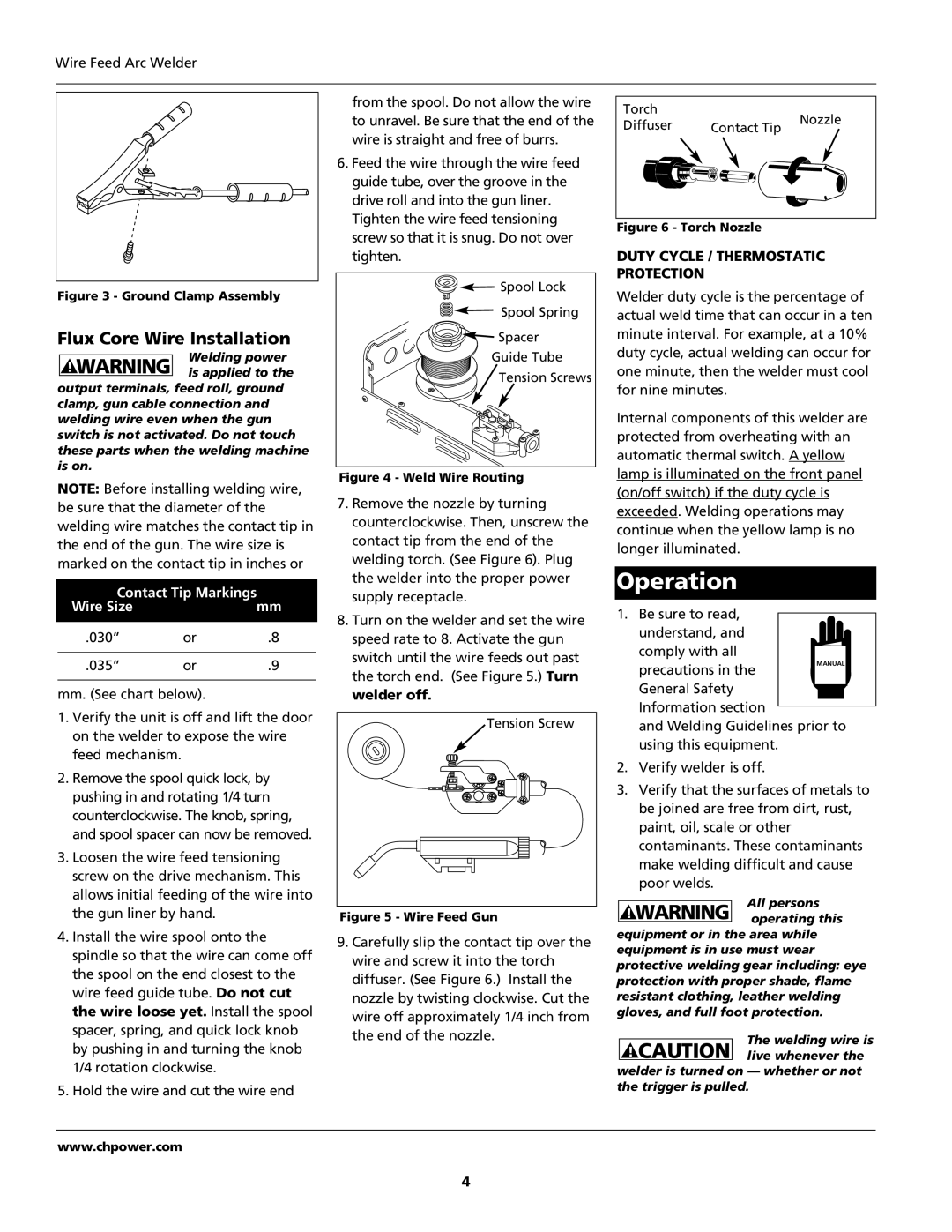

![]() Spool Lock

Spool Lock

Spool Spring

![]() Spacer

Spacer

Guide Tube

![]() Tension Screws

Tension Screws

Figure 4 - Weld Wire Routing

7. Remove the nozzle by turning |

counterclockwise. Then, unscrew the |

contact tip from the end of the |

welding torch. (See Figure 6). Plug |

Torch |

| Nozzle | |

Diffuser | Contact Tip | ||

|

Figure 6 - Torch Nozzle

DUTY CYCLE / THERMOSTATIC PROTECTION

Welder duty cycle is the percentage of actual weld time that can occur in a ten minute interval. For example, at a 10% duty cycle, actual welding can occur for one minute, then the welder must cool for nine minutes.

Internal components of this welder are protected from overheating with an automatic thermal switch. A yellow lamp is illuminated on the front panel (on/off switch) if the duty cycle is exceeded. Welding operations may continue when the yellow lamp is no longer illuminated.

Contact Tip Markings

| Wire Size |

| mm | |

|

|

|

|

|

| .030” | or | .8 |

|

|

|

|

|

|

| .035” | or | .9 |

|

|

|

|

|

|

|

|

|

|

|

mm. (See chart below).

1. Verify the unit is off and lift the door |

the welder into the proper power |

supply receptacle. |

8. Turn on the welder and set the wire |

speed rate to 8. Activate the gun |

switch until the wire feeds out past |

the torch end. (See Figure 5.) Turn |

welder off. |

Operation

1.Be sure to read, understand, and comply with all

precautions in the General Safety Information section

MANUAL

on the welder to expose the wire |

feed mechanism. |

2. Remove the spool quick lock, by |

pushing in and rotating 1/4 turn |

counterclockwise. The knob, spring, |

and spool spacer can now be removed. |

3. Loosen the wire feed tensioning |

screw on the drive mechanism. This |

allows initial feeding of the wire into |

the gun liner by hand. |

4. Install the wire spool onto the |

spindle so that the wire can come off |

the spool on the end closest to the |

wire feed guide tube. Do not cut |

the wire loose yet. Install the spool |

spacer, spring, and quick lock knob |

by pushing in and turning the knob |

1/4 rotation clockwise. |

5. Hold the wire and cut the wire end |

Tension Screw

Figure 5 - Wire Feed Gun

9.Carefully slip the contact tip over the wire and screw it into the torch diffuser. (See Figure 6.) Install the nozzle by twisting clockwise. Cut the wire off approximately 1/4 inch from the end of the nozzle.

and Welding Guidelines prior to using this equipment.

2.Verify welder is off.

3.Verify that the surfaces of metals to be joined are free from dirt, rust, paint, oil, scale or other contaminants. These contaminants make welding difficult and cause poor welds.

All persons operating this

equipment or in the area while equipment is in use must wear protective welding gear including: eye protection with proper shade, flame resistant clothing, leather welding gloves, and full foot protection.

The welding wire is

! CAUTION live whenever the welder is turned on — whether or not the trigger is pulled.

www.chpower.com

4