50SD specifications

The Carrier 50SD is a cutting-edge split system air conditioning unit designed for both commercial and residential applications. With its advanced technology and robust features, it stands out in the market as an efficient solution for heating and cooling needs.One of the main features of the Carrier 50SD is its high energy efficiency. The unit utilizes a high-efficiency scroll compressor, which not only provides reliable comfort but also significantly reduces energy consumption. This efficiency is further enhanced by the unit’s ability to operate at different cooling capacities, adapting to the specific demands of the environment. The 50SD boasts a SEER (Seasonal Energy Efficiency Ratio) rating that often exceeds industry standards, making it an environmentally friendly choice for users.

Incorporating sophisticated technologies, the Carrier 50SD is equipped with an advanced microprocessor control system. This system continuously monitors the indoor climate and adjusts the operation of the unit accordingly, ensuring optimal comfort levels while minimizing energy use. The unit also offers variable speed operation, allowing for precise temperature control and quieter performance.

Durability and reliability are key characteristics of the Carrier 50SD. The unit is constructed with high-quality materials designed to withstand harsh weather conditions and extensive use. Its condenser coil is made from a galvanized steel that is resistant to corrosion, ensuring longevity and a consistent performance through the seasons.

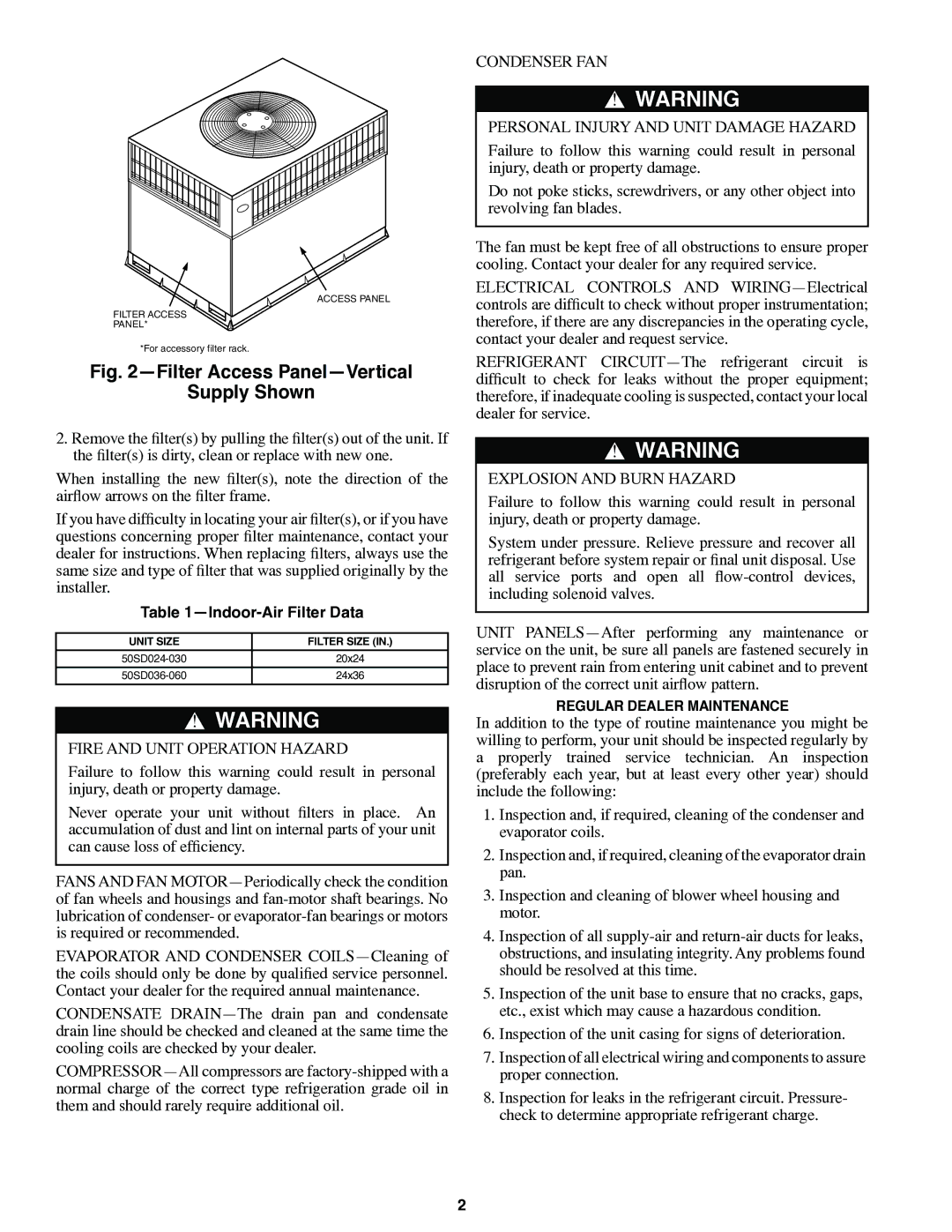

Another significant aspect of the Carrier 50SD is its advanced filtration system. The unit is equipped with a high-efficiency air filter that captures airborne contaminants and allergens, improving indoor air quality. Regular maintenance is made easy with accessible filter access points, ensuring that users can keep their systems running smoothly.

Additionally, the Carrier 50SD features compatibility with various smart thermostats, allowing homeowners and businesses to integrate their cooling systems into their home or building automation systems for enhanced control and convenience. Remote management options enable users to monitor and adjust settings from anywhere, maximizing efficiency and comfort.

In conclusion, the Carrier 50SD represents a harmonious blend of efficiency, reliability, and advanced technology, making it an exceptional choice for any heating and cooling environment. Its energy-saving capabilities, robust construction, and user-friendly features embody the future of HVAC technology, meeting the demands of modern users while prioritizing comfort and sustainability.