ERVCCSVB1100, HRVCCSHB1100, ERVCCSHB1100, HRVCCSVB1100 specifications

The Carrier ERVCCSVB1100, HRVCCSVB1100, HRVCCSHB1100, and ERVCCSHB1100 represent the latest advancements in residential and commercial ventilation systems. These systems are designed to enhance indoor air quality while ensuring energy efficiency, making them ideal solutions for modern buildings.One of the main features of these units is their recovery ventilation technology. Both the Energy Recovery Ventilator (ERV) and Heat Recovery Ventilator (HRV) options are engineered to efficiently transfer heat and moisture between incoming and outgoing air streams. This process reduces energy consumption by pre-conditioning fresh air, thereby minimizing the workload on heating and cooling systems.

The ERVCCSVB1100 and ERVCCSHB1100 models are particularly well-suited for humid climates where moisture control is critical. They utilize a sophisticated enthalpy exchange process, which allows excess humidity to be transferred from the stale air to the incoming fresh air, thereby reducing the burden on air conditioning systems and maintaining optimal indoor humidity levels. This feature is essential for enhancing occupant comfort and safeguarding building materials from moisture-related damage.

On the other hand, the HRVCCSVB1100 and HRVCCSHB1100 units shine in drier climates where humidity control is less of a concern. These systems focus on heat recovery, effectively transferring thermal energy without exchanging moisture. This is particularly advantageous during winter months, as they provide fresh air while conserving precious heat, thus optimizing energy utilization and contributing to lower utility bills.

Another critical characteristic of all four models is their quiet operation. Designed with sound-dampening technologies, they ensure minimal noise disturbance, thereby maintaining a peaceful indoor environment. This is especially valuable in residential settings or commercial spaces that require a distraction-free atmosphere.

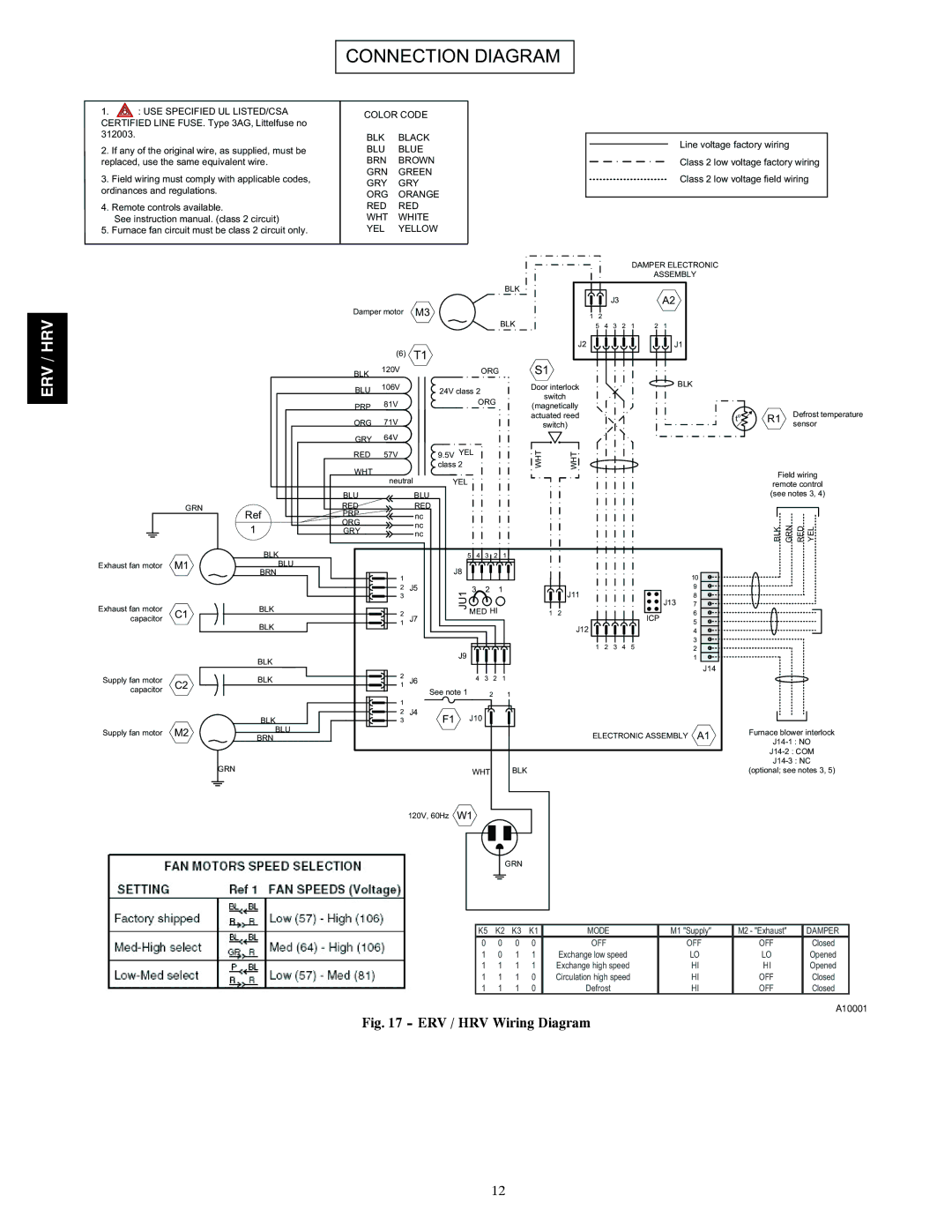

Additionally, the units come with intelligent controls that allow users to monitor and adjust settings according to their specific needs. Features such as programmable timers and remote access capabilities provide convenience and flexibility for users, enabling them to optimize their indoor air quality effortlessly.

In summary, Carrier's ERVCCSVB1100, HRVCCSVB1100, HRVCCSHB1100, and ERVCCSHB1100 models offer a comprehensive suite of features, advanced technologies, and characteristics tailored to meet the demands of modern indoor environments. By integrating energy recovery ventilation with user-friendly controls, they set a new standard for efficiency, comfort, and air quality in various building types.