325DL specifications

The CAT 325DL is a technologically advanced hydraulic excavator designed to deliver exceptional performance, efficiency, and durability in various construction and earth-moving applications. With a weight of approximately 25 tons, this machine strikes a balance between power and versatility, making it suitable for tasks such as excavation, grading, and material handling.One of the standout features of the CAT 325DL is its powerful engine. Equipped with a Cat C6.4 engine, it offers an impressive net power output of around 175 horsepower. This robust engine ensures optimal performance even in demanding conditions, allowing operators to tackle tough materials with ease. The machine’s design emphasizes fuel efficiency, helping reduce operational costs while minimizing environmental impact.

The excavator’s hydraulic system is designed for precision and responsiveness. The load-sensing hydraulics deliver consistent power to the attachments, enhancing productivity and reducing cycle times. Operators can enjoy a smooth and controlled operation, which is essential for intricate tasks. Additionally, the CAT 325DL features a state-of-the-art electronic control module that optimizes the hydraulic flow based on the specific task, improving efficiency further.

For enhanced operator comfort, the CAT 325DL boasts a spacious and ergonomic cab. It is equipped with high-visibility windows and excellent all-round visibility, which reduces blind spots and promotes safety on-site. The intuitive control layout, coupled with adjustable seating, allows operators to work for extended periods without discomfort. Advanced monitoring and diagnostic systems provide real-time data, enabling proactive maintenance and minimizing downtime.

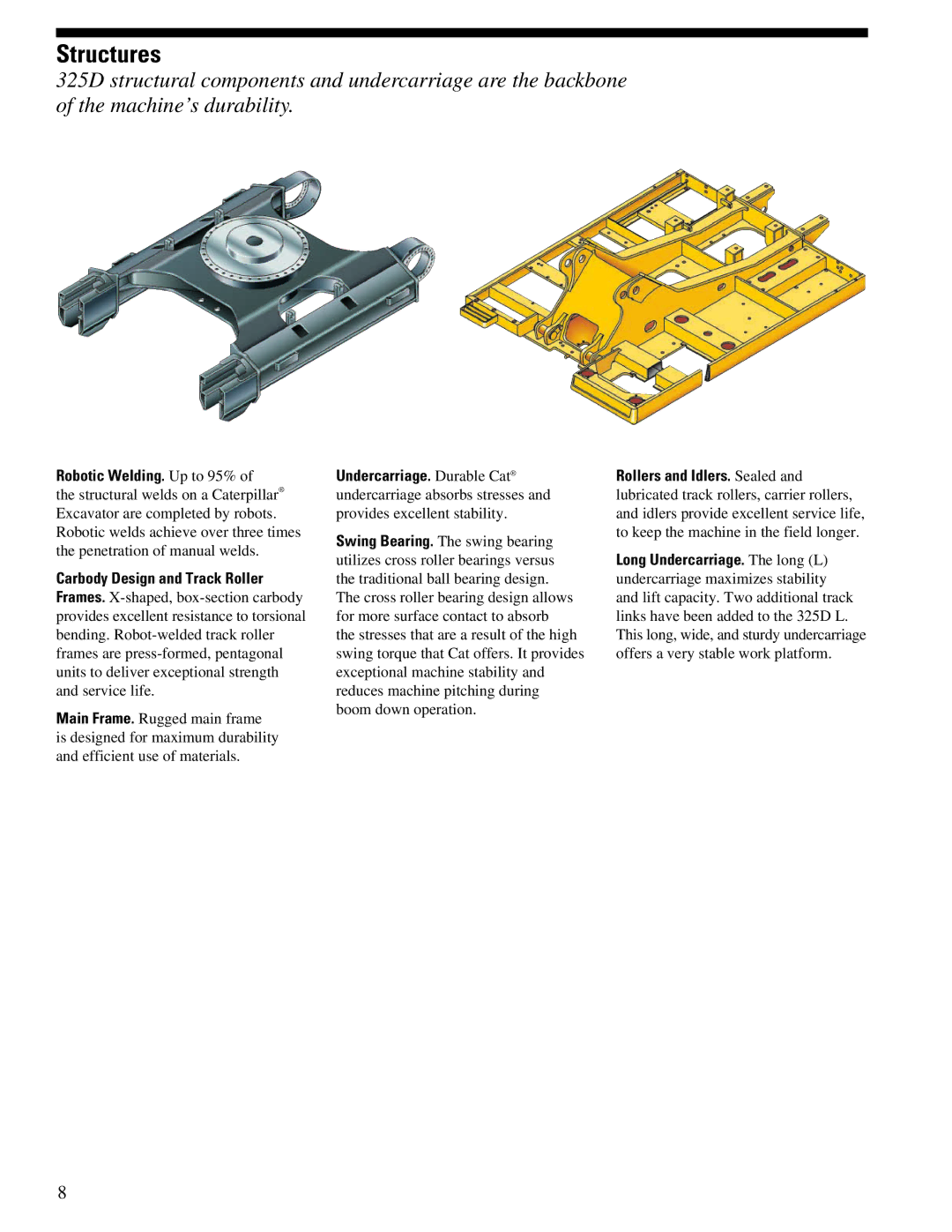

In terms of versatility, the CAT 325DL is compatible with a wide range of attachments, including buckets, grapples, and hydraulic breakers, making it adaptable to various tasks and working conditions. Its robust undercarriage and durable tracks ensure stability and traction on uneven surfaces, allowing for effective operation on both residential and commercial job sites.

The CAT 325DL is also designed with maintenance in mind. Key components are easily accessible, simplifying routine checks and servicing. This design philosophy enhances the machine's longevity and reliability, making it a valuable investment for contractors looking for a dependable excavator.

Overall, the CAT 325DL combines advanced technology, operator comfort, and rugged durability, making it a standout choice for heavy-duty applications in the construction industry.