GAS CONNECTOR | GB Cat: II 2H3+ |

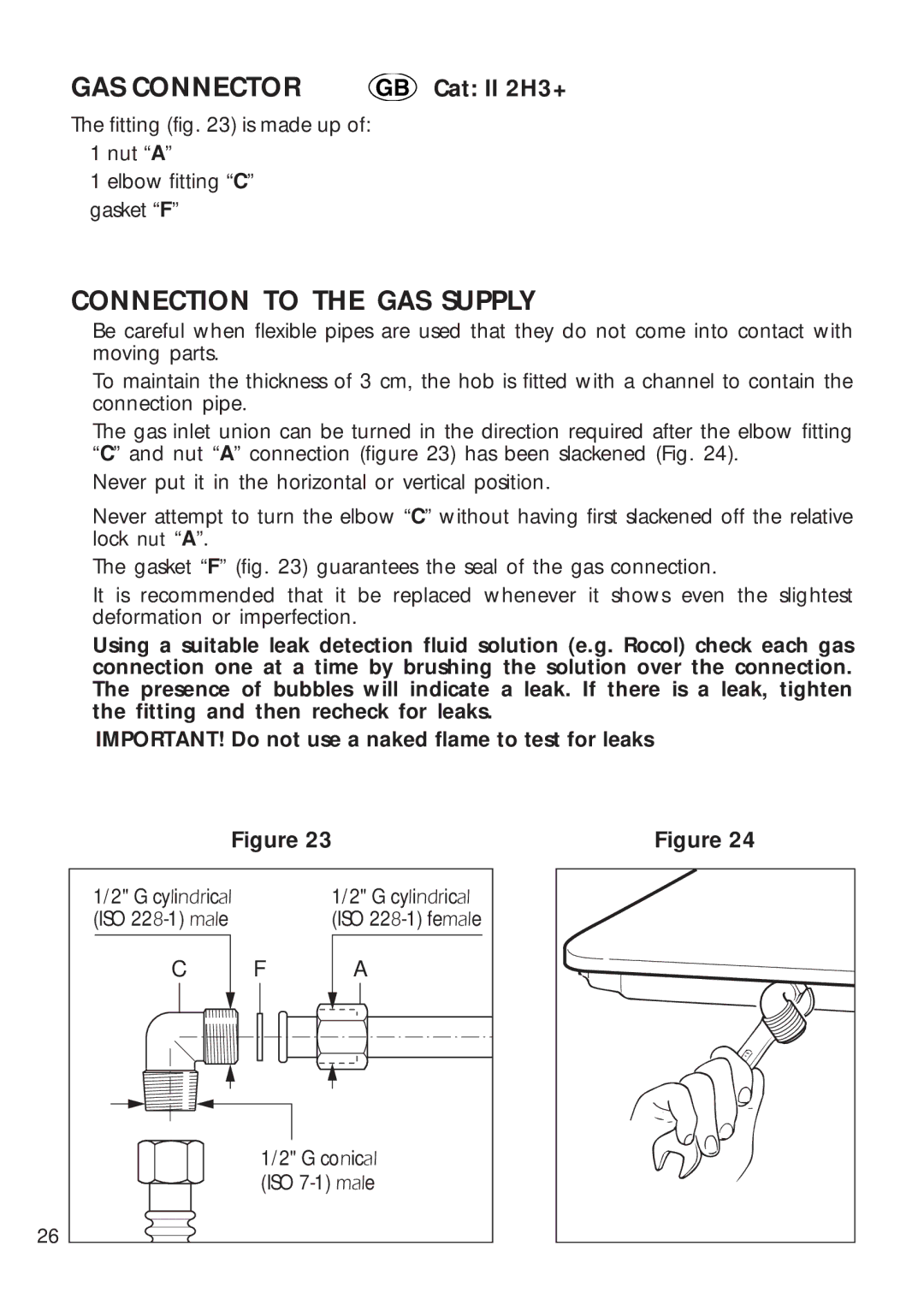

The fitting (fig. 23) is made up of:

✓1 nut “A”

✓1 elbow fitting “C”

✓gasket “F”

CONNECTION TO THE GAS SUPPLY

✓Be careful when flexible pipes are used that they do not come into contact with moving parts.

✓To maintain the thickness of 3 cm, the hob is fitted with a channel to contain the connection pipe.

✓The gas inlet union can be turned in the direction required after the elbow fitting “C” and nut “A” connection (figure 23) has been slackened (Fig. 24).

✓Never put it in the horizontal or vertical position.

✓Never attempt to turn the elbow “C” without having first slackened off the relative lock nut “A”.

✓The gasket “F” (fig. 23) guarantees the seal of the gas connection.

It is recommended that it be replaced whenever it shows even the slightest deformation or imperfection.

✓Using a suitable leak detection fluid solution (e.g. Rocol) check each gas connection one at a time by brushing the solution over the connection. The presence of bubbles will indicate a leak. If there is a leak, tighten the fitting and then recheck for leaks.

IMPORTANT! Do not use a naked flame to test for leaks

Figure 23 | Figure 24 |

1/2" G cylindrical |

| 1/2" G cylindrical |

(ISO |

| (ISO |

C | F | A |

| 1/2" G conical | |

| (ISO | |

26 |

|

|