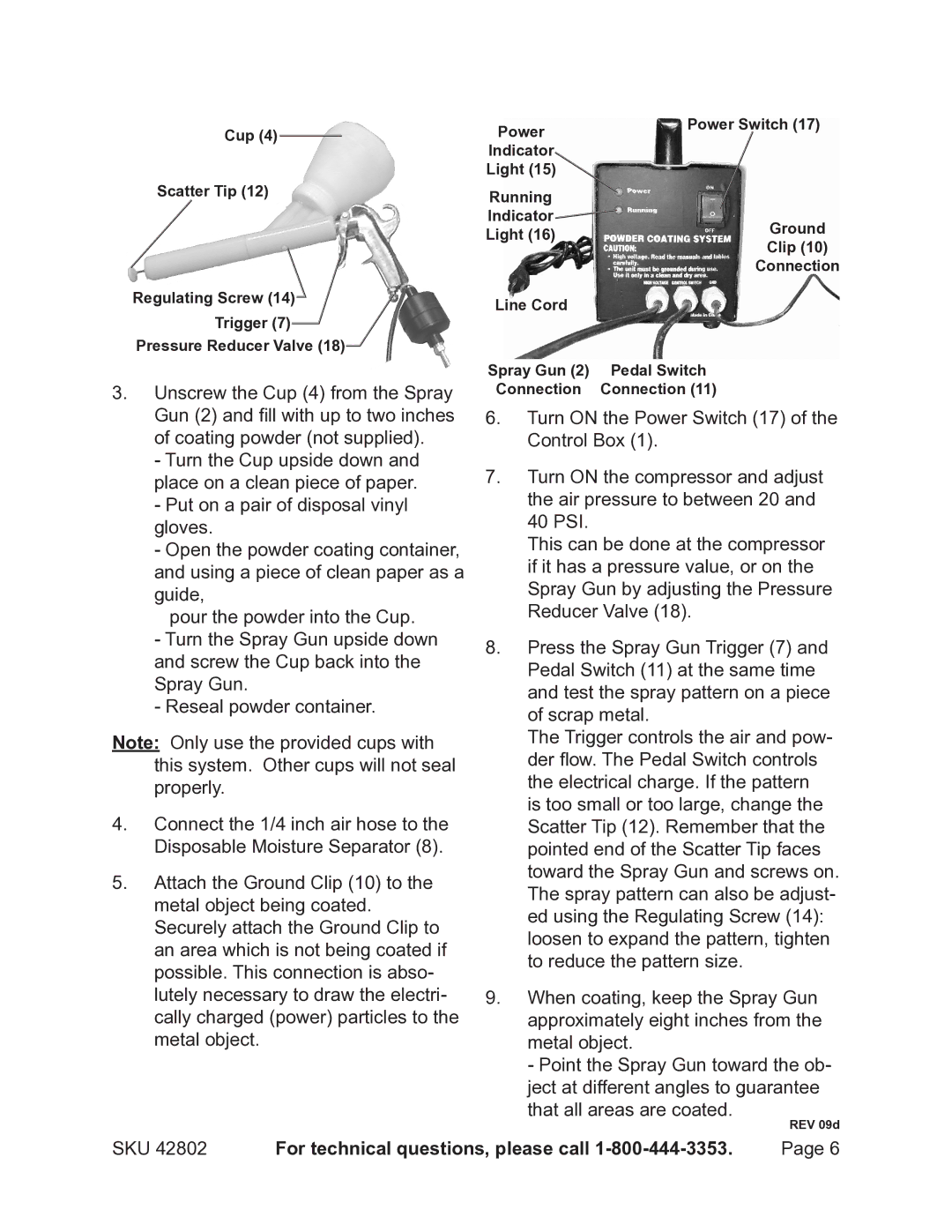

Cup (4)

Scatter Tip (12)

Regulating Screw (14)

Trigger (7)

Pressure Reducer Valve (18)

3.Unscrew the Cup (4) from the Spray

Gun (2) and fill with up to two inches of coating powder (not supplied).

-Turn the Cup upside down and place on a clean piece of paper.

-Put on a pair of disposal vinyl gloves.

-Open the powder coating container, and using a piece of clean paper as a guide,

pour the powder into the Cup.

-Turn the Spray Gun upside down and screw the Cup back into the Spray Gun.

-Reseal powder container.

Note: Only use the provided cups with this system. Other cups will not seal properly.

4.Connect the 1/4 inch air hose to the Disposable Moisture Separator (8).

5.Attach the Ground Clip (10) to the metal object being coated. Securely attach the Ground Clip to an area which is not being coated if possible. This connection is abso- lutely necessary to draw the electri- cally charged (power) particles to the metal object.

Power | Power Switch (17) |

| |

Indicator |

|

Light (15) |

|

Running

Indicator![]()

Light (16)Ground

Clip (10)

Connection

Line Cord |

|

Spray Gun (2) | Pedal Switch |

Connection | Connection (11) |

6.Turn ON the Power Switch (17) of the Control Box (1).

7.Turn ON the compressor and adjust the air pressure to between 20 and 40 PSI.

This can be done at the compressor if it has a pressure value, or on the Spray Gun by adjusting the Pressure Reducer Valve (18).

8.Press the Spray Gun Trigger (7) and Pedal Switch (11) at the same time and test the spray pattern on a piece of scrap metal.

The Trigger controls the air and pow- der flow. The Pedal Switch controls the electrical charge. If the pattern is too small or too large, change the Scatter Tip (12). Remember that the pointed end of the Scatter Tip faces toward the Spray Gun and screws on. The spray pattern can also be adjust- ed using the Regulating Screw (14): loosen to expand the pattern, tighten to reduce the pattern size.

9.When coating, keep the Spray Gun approximately eight inches from the metal object.

- Point the Spray Gun toward the ob- ject at different angles to guarantee that all areas are coated.

REV 09d

SKU 42802 | For technical questions, please call | Page 6 |