AFD Applications

Ease of Incorporation into Machine or Process

•Extensive range of mounting clamps

•Control interfaces to link AFD(E) to other equipment through pneumatics or electrically

•Single signal required for AFD(E) to perform cycle

•Output signals at datum and depth

•Electric motor mounting on 200, 400 and 600 series can be rotated through 180º

Modular Design

•Flexibility of unit function and speed

•Common components in differing models reducing inventory

•Multiple spindle head options

•Drill and tapping options for all models

Model Type

Pneumatic Feed and Drive

AFD205, AFD215 | 0.22kW (0.29HP) |

AFD415 | 0.38kW (0.50HP) |

AFD/AFT60 | 0.52kW (0.70HP) |

Pneumatic Feed, Electric Drive | |

AFDE200 | 0.25kW (0.33HP) |

AFDE400, AFDE600 | 0.33kW (0.40HP) |

AFDE410, AFDE610 | 0.75kW (1.00HP) |

AFDE620 | 1.10kW (1.50HP) |

AFDE700 | 1.50kW (2.00HP) |

AFDE710 | 2.20kW (3.00HP) |

Electric Feed and Drive via Leadscrew | |

AFTE270 | 0.18kW (0.24HP) |

AFTE470 | 0.38kW (0.50HP) |

AFTE480 | 0.75kW (1.00HP) |

Output Spindle**

Output spindle to be supplied.

How to Order

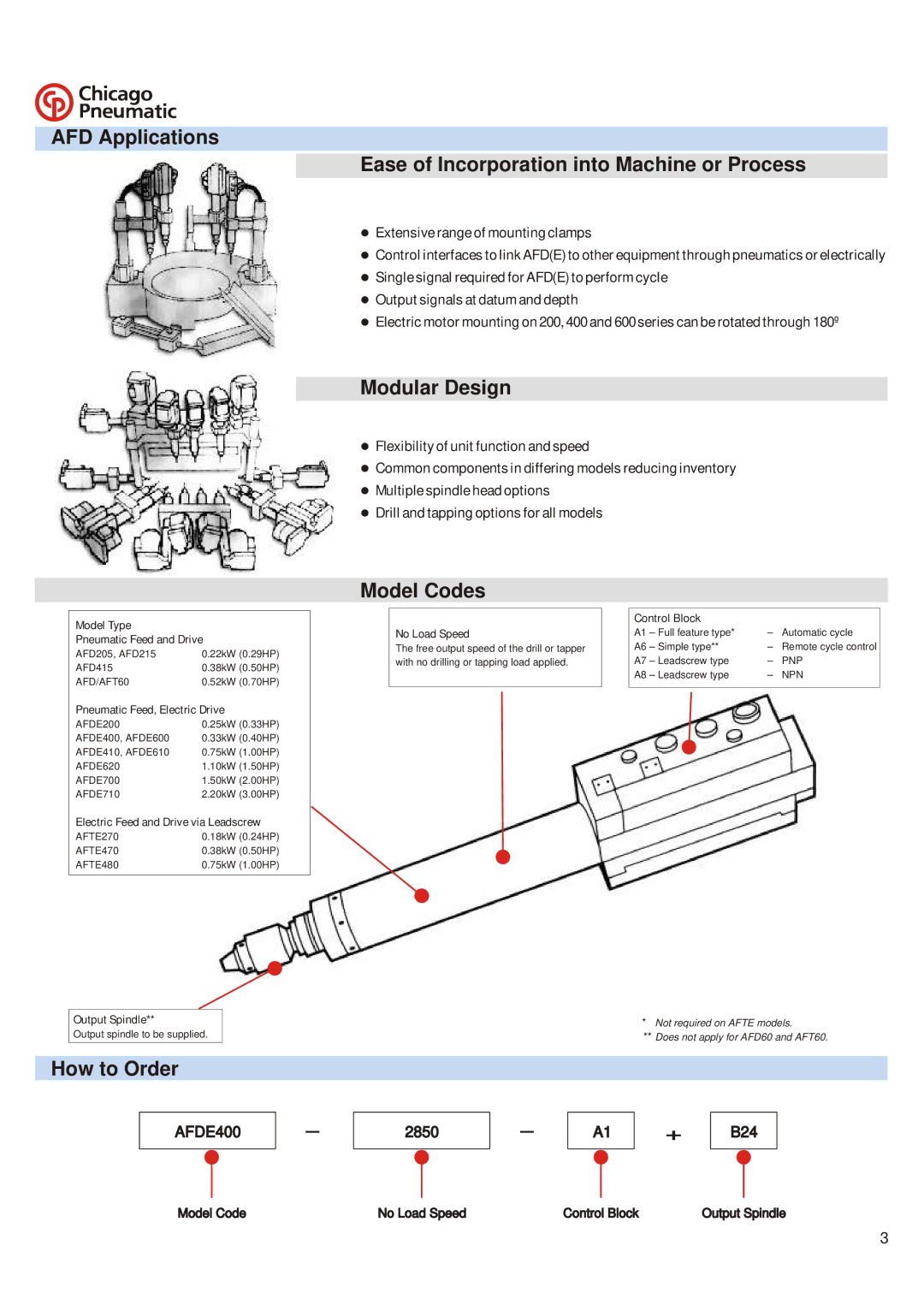

Model Codes

No Load Speed

The free output speed of the drill or tapper with no drilling or tapping load applied.

Control Block |

|

| |

A1 | – Full feature type* | – | Automatic cycle |

A6 | – Simple type** | – | Remote cycle control |

A7 | – Leadscrew type | – | PNP |

A8 | – Leadscrew type | – | NPN |

|

|

|

|

*Not required on AFTE models.

**Does not apply for AFD60 and AFT60.

AFDE400 | — |

|

|

Model Code

2850 | — | A1 | + | B24 |

|

|

|

|

|

No Load Speed | Control Block | Output Spindle |

3