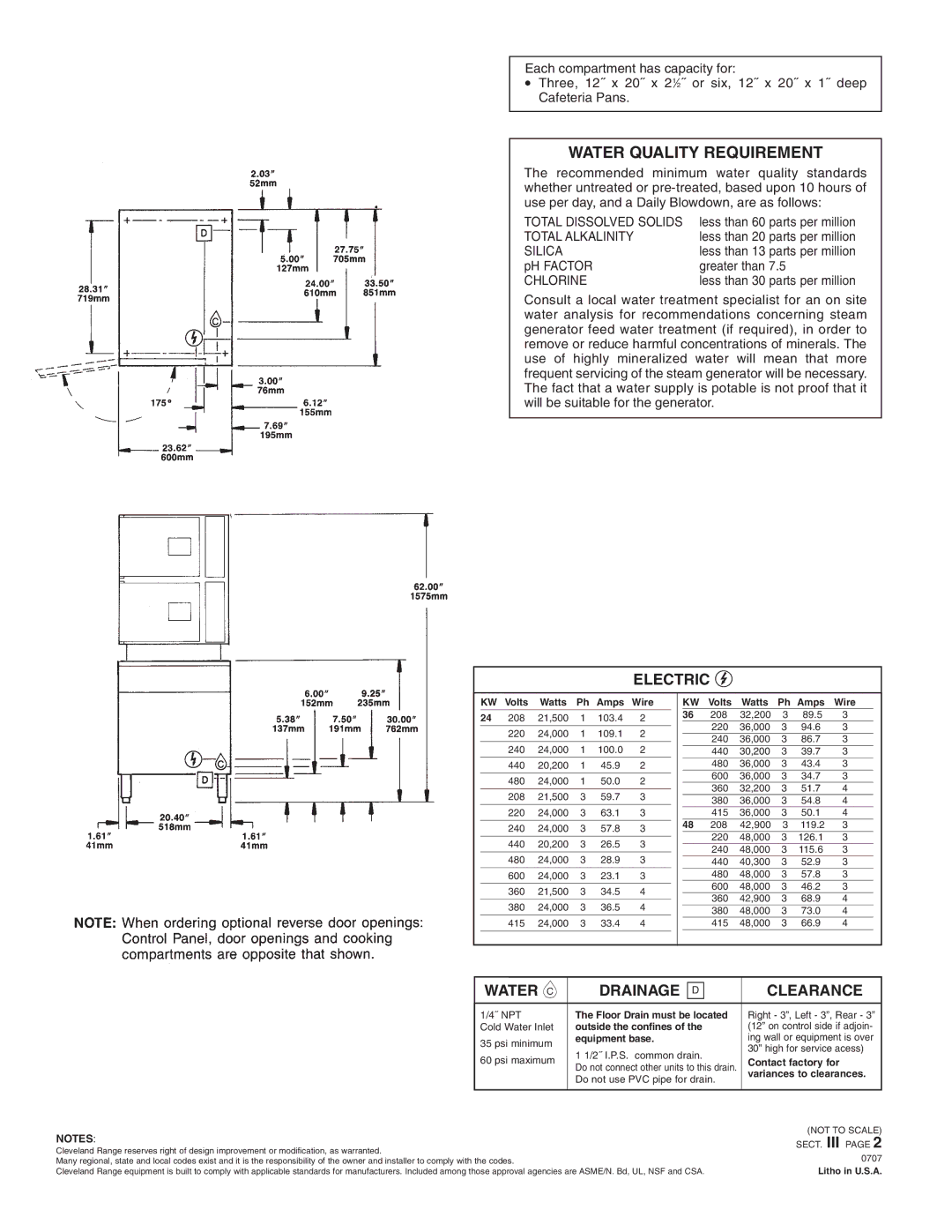

24-CEM-36, 24-CEM-24, 24-CEM-48 specifications

Cleveland Range has long been a trusted name in the commercial kitchen sector, renowned for its high-performance cooking equipment that meets the needs of restaurants, catering companies, and institutional kitchens. Among its impressive lineup, the Cleveland Range 24-CEM-48, 24-CEM-24, and 24-CEM-36 models stand out, offering versatility, efficiency, and advanced technology tailored for various cooking applications.The Cleveland Range 24-CEM series features a sleek and durable design that optimally utilizes space while maximizing cooking capabilities. Each unit in this series is constructed from high-quality stainless steel, ensuring resistance to corrosion and wear, which is essential for high-demand environments. With a compact footprint, these units can fit seamlessly into any kitchen layout, making them ideal for establishments with limited space.

One of the standout features of the Cleveland Range 24-CEM series is its combination of electric and steam cooking technologies. This advanced approach allows chefs to achieve superior cooking results, with steam cooking offering excellent moisture retention and flavor enhancement. The efficient steam generation system provides rapid heating and consistent temperature control, resulting in perfectly cooked dishes every time.

These models also come equipped with a user-friendly digital control panel, allowing operators to easily set and monitor cooking times and temperatures. The intuitive interface streamlines operations, helping staff to focus on food quality and service speed. Moreover, the Cleveland Range 24-CEM series incorporates safety features, including automatic shut-off and temperature monitoring, which helps prevent overheating and ensures safe operation.

Maintenance is made easy with the Cleveland Range 24-CEM cooking units, thanks to their accessible design that facilitates cleaning and service. The removable parts and smooth surfaces help maintain high hygiene standards, which is crucial in any commercial kitchen.

In summary, the Cleveland Range 24-CEM-48, 24-CEM-24, and 24-CEM-36 models are engineered to deliver exceptional performance and versatility tailored for professional kitchens. With features like durable construction, advanced steam cooking technology, user-friendly controls, and easy maintenance, these units are designed to enhance the efficiency and effectiveness of culinary operations, making them an invaluable asset for kitchen professionals everywhere.