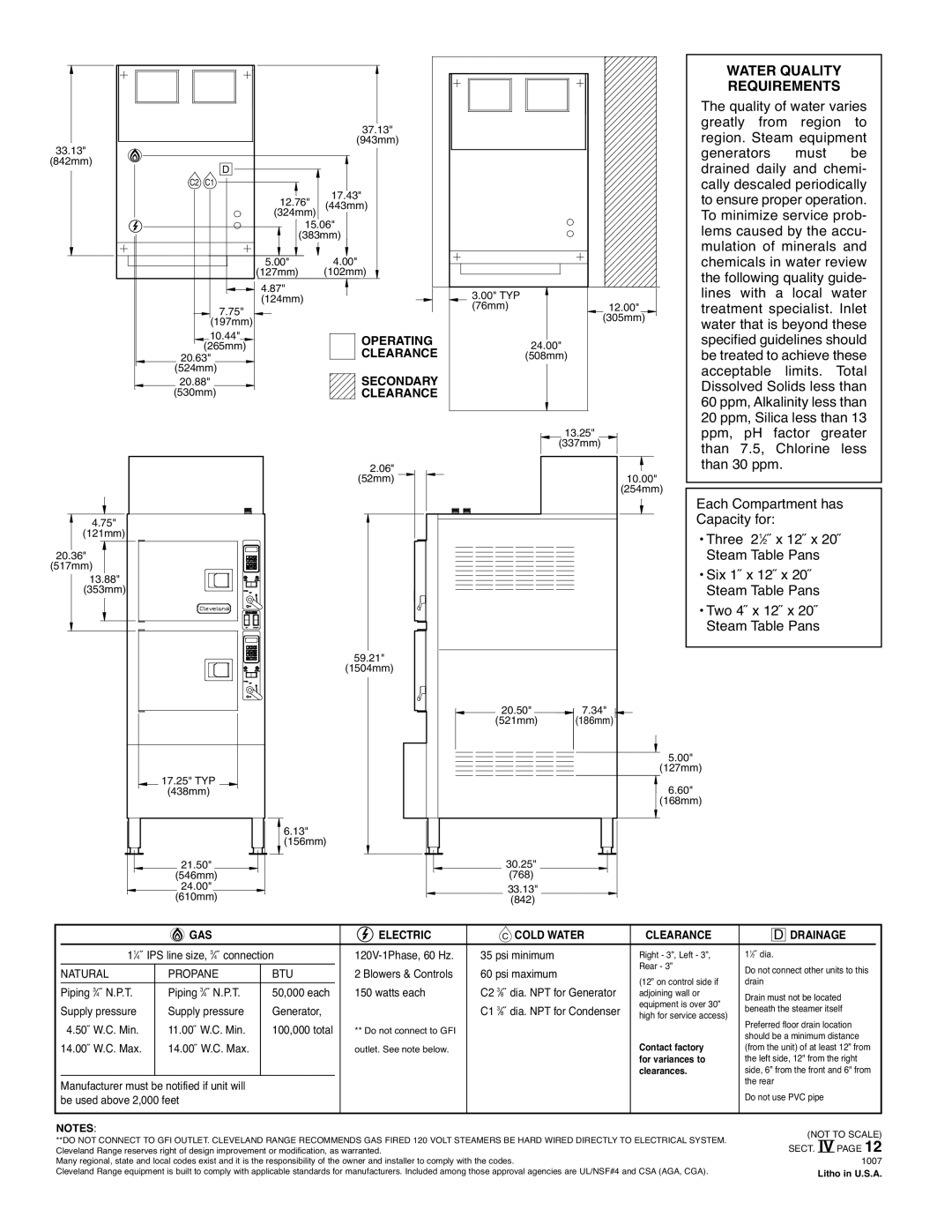

24CGA6.2S specifications

The Cleveland Range 24CGA6.2S is a highly efficient, versatile cooking equipment designed to meet the demands of busy commercial kitchens. This model, known for its robust construction and advanced technology, is favored by chefs who require reliable performance and exceptional quality in their culinary operations.One of the defining features of the Cleveland Range 24CGA6.2S is its impressive cooking capacity. With a 6.2-gallon solid-state steam generator, it provides ample steam for cooking a variety of foods, making it ideal for high-volume food service environments. This capacity ensures that chefs can prepare large quantities of meals simultaneously, enhancing productivity during peak serving times.

The unit is constructed from durable stainless steel, known for its resilience and ease of maintenance. This choice of material not only ensures longevity but also provides a hygienic cooking surface, a crucial factor in any kitchen. The Cleveland Range 24CGA6.2S is designed with a space-saving footprint, allowing it to fit seamlessly into kitchens with limited room without compromising on functionality.

Another key feature of the 24CGA6.2S is its innovative control system. The intuitive digital control interface allows for precise temperature adjustments and cooking times, enabling chefs to achieve consistent results with various recipes. This technology reduces the risk of error, ensuring that dishes are cooked to perfection every time.

The Cleveland Range 24CGA6.2S also prides itself on energy efficiency. Its design minimizes energy consumption while maximizing output, making it not only a great choice for performance but also for reducing operational costs. This eco-friendly approach aligns with the growing emphasis on sustainability in the food service industry.

The self-diagnostic controls of the Cleveland Range 24CGA6.2S further streamline operation by alerting users to any potential issues, allowing for proactive maintenance. This feature reduces downtime and ensures that the kitchen runs smoothly, even during busy shifts.

In conclusion, the Cleveland Range 24CGA6.2S stands out as an essential piece of equipment for any commercial kitchen. Its combination of high capacity, advanced digital controls, energy efficiency, and durable construction makes it a reliable choice for chefs looking to elevate their cooking processes and serve high-quality meals efficiently. Whether boiling, steaming, or any other cooking method, this unit is engineered to perform exceptionally well in the fast-paced foodservice industry.