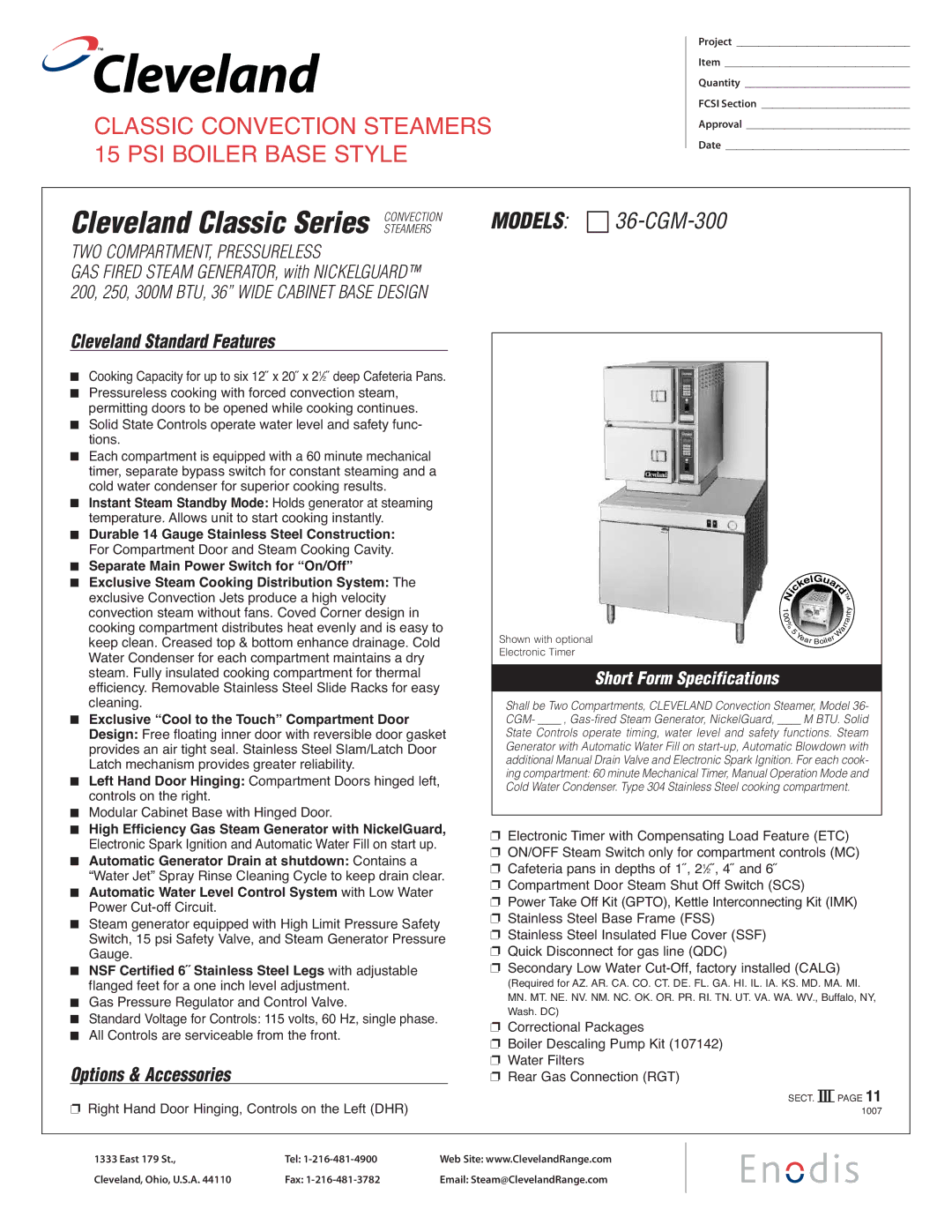

36-CGM-300 specifications

The Cleveland Range 36-CGM-300 is a commercially designed convection steamer that stands out in the field of food service equipment. This unit is known for its powerful performance and efficiency, catering to the needs of restaurants, schools, hospitals, and other food establishments that require large quantities of cooked food. With its robust build and advanced features, the Cleveland Range 36-CGM-300 enhances cooking capabilities while maintaining high standards of food quality.One of the main features of the Cleveland Range 36-CGM-300 is its generous cooking capacity. It offers a total of three cooking compartments, each capable of accommodating multiple full-size steam table pans. This allows for versatile cooking options, as operators can steam vegetables, seafood, or even reheat prepared dishes simultaneously. The unique compartment design ensures that different types of foods can be cooked together without flavor contamination.

The Cleveland Range 36-CGM-300 incorporates advanced technology aimed at maximizing efficiency and minimizing energy consumption. Its digital control system allows for precise temperature adjustments and cooking times, ensuring consistent results with every use. The unit is equipped with a high-efficiency steam generation system that delivers quick heat-up times and optimal performance. Additionally, it features a water fill indicator and automatic water level controls for added convenience.

Another significant characteristic of the Cleveland Range 36-CGM-300 is its built-in self-diagnostics system, which alerts users of any maintenance needs or operational issues. This feature enhances reliability, ensuring that the steamer operates smoothly with minimal downtime, a crucial factor in busy kitchens.

The Cleveland Range 36-CGM-300 is also designed with food safety in mind. The unit's steam environment helps eliminate harmful bacteria and ensures that food is cooked thoroughly, preserving flavor and nutrients. With a durable stainless steel construction, the steamer is easy to clean and maintain, making it an ideal choice for high-volume food service operations.

In conclusion, the Cleveland Range 36-CGM-300 is a powerful and efficient convection steamer that meets the demands of large-scale food production. Its ample cooking capacity, advanced technology, and focus on food safety make it a reliable solution for any commercial kitchen looking to elevate its steaming capabilities. Investing in the Cleveland Range 36-CGM-300 ensures that food service operators can deliver high-quality meals while improving efficiency and productivity in their kitchens.