Section VI Appendix (Continued)

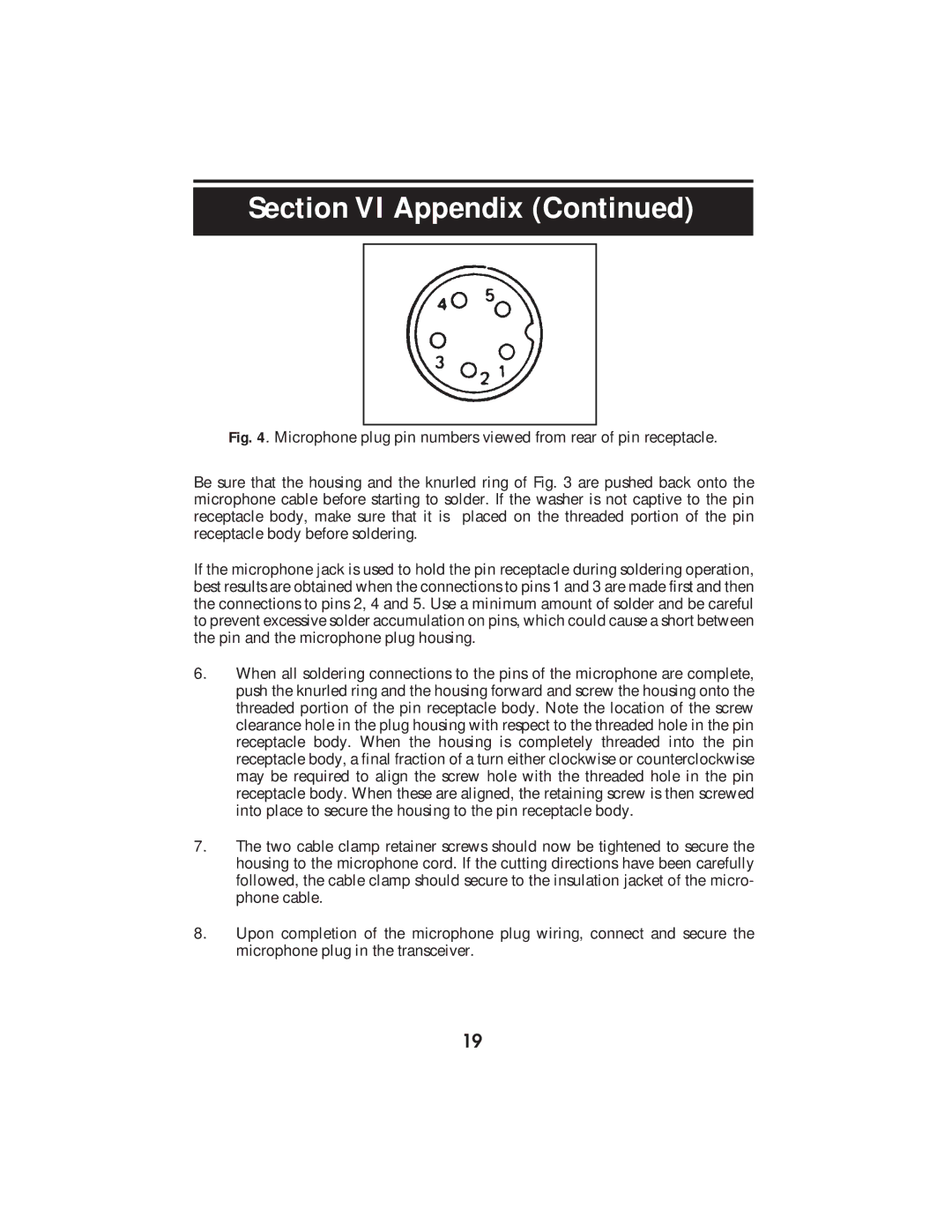

Fig. 4. Microphone plug pin numbers viewed from rear of pin receptacle.

Be sure that the housing and the knurled ring of Fig. 3 are pushed back onto the microphone cable before starting to solder. If the washer is not captive to the pin receptacle body, make sure that it is placed on the threaded portion of the pin receptacle body before soldering.

If the microphone jack is used to hold the pin receptacle during soldering operation, best results are obtained when the connections to pins 1 and 3 are made first and then the connections to pins 2, 4 and 5. Use a minimum amount of solder and be careful to prevent excessive solder accumulation on pins, which could cause a short between the pin and the microphone plug housing.

6.When all soldering connections to the pins of the microphone are complete, push the knurled ring and the housing forward and screw the housing onto the threaded portion of the pin receptacle body. Note the location of the screw clearance hole in the plug housing with respect to the threaded hole in the pin receptacle body. When the housing is completely threaded into the pin receptacle body, a final fraction of a turn either clockwise or counterclockwise may be required to align the screw hole with the threaded hole in the pin receptacle body. When these are aligned, the retaining screw is then screwed into place to secure the housing to the pin receptacle body.

7.The two cable clamp retainer screws should now be tightened to secure the housing to the microphone cord. If the cutting directions have been carefully followed, the cable clamp should secure to the insulation jacket of the micro- phone cable.

8.Upon completion of the microphone plug wiring, connect and secure the microphone plug in the transceiver.

19