RLL233 | Issue 4 Aug 2007 |

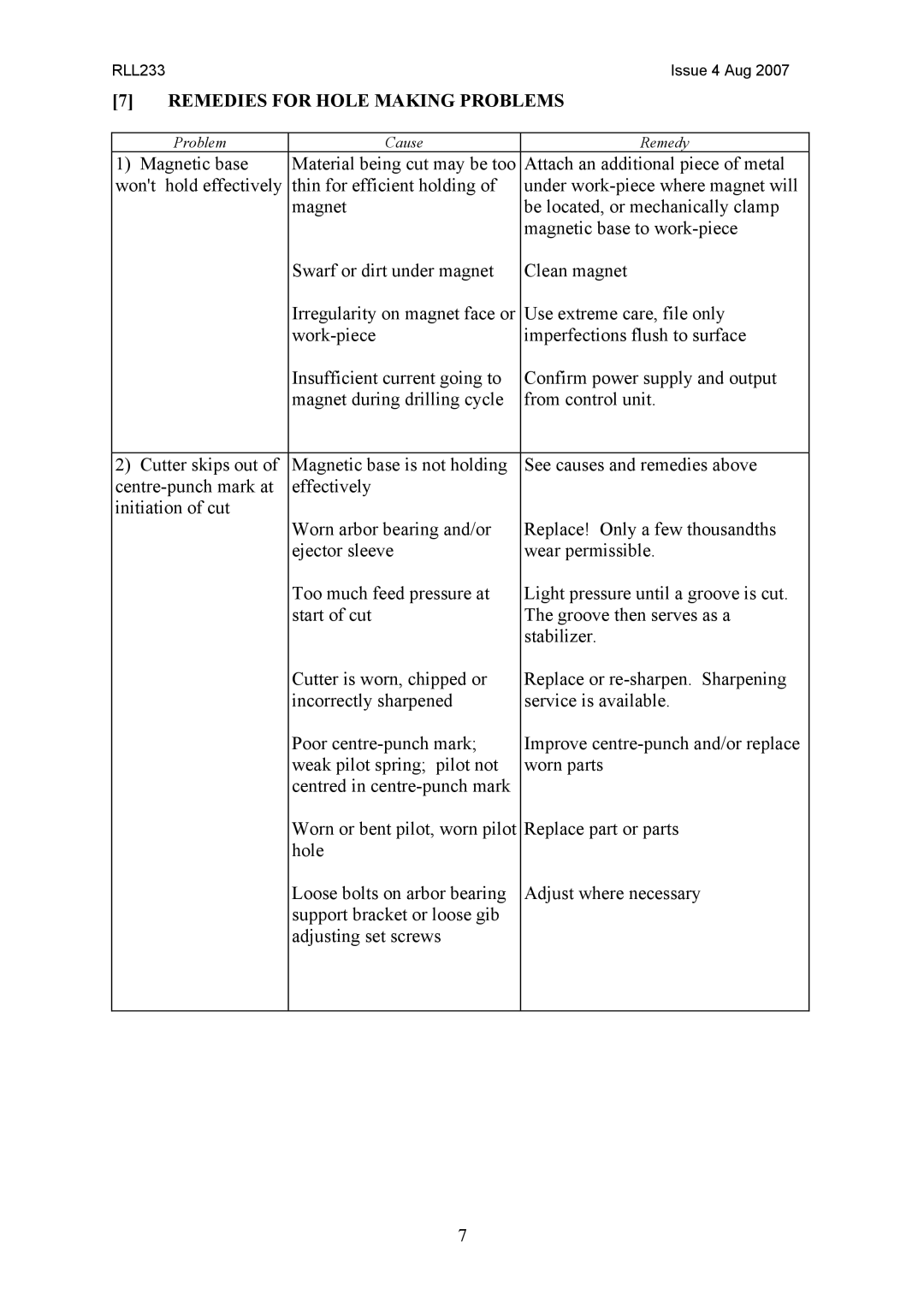

[7]REMEDIES FOR HOLE MAKING PROBLEMS

Problem | Cause | Remedy |

1) Magnetic base | Material being cut may be too | Attach an additional piece of metal |

won't hold effectively | thin for efficient holding of | under |

| magnet | be located, or mechanically clamp |

|

| magnetic base to |

| Swarf or dirt under magnet | Clean magnet |

| Irregularity on magnet face or | Use extreme care, file only |

| imperfections flush to surface | |

| Insufficient current going to | Confirm power supply and output |

| magnet during drilling cycle | from control unit. |

|

|

|

2) Cutter skips out of | Magnetic base is not holding | See causes and remedies above |

effectively |

| |

initiation of cut |

|

|

| Worn arbor bearing and/or | Replace! Only a few thousandths |

| ejector sleeve | wear permissible. |

| Too much feed pressure at | Light pressure until a groove is cut. |

| start of cut | The groove then serves as a |

|

| stabilizer. |

| Cutter is worn, chipped or | Replace or |

| incorrectly sharpened | service is available. |

| Poor | Improve |

| weak pilot spring; pilot not | worn parts |

| centred in |

|

| Worn or bent pilot, worn pilot | Replace part or parts |

| hole |

|

| Loose bolts on arbor bearing | Adjust where necessary |

| support bracket or loose gib |

|

| adjusting set screws |

|

|

|

|

7