RLL233 |

| Issue 4 Aug 2007 |

|

|

|

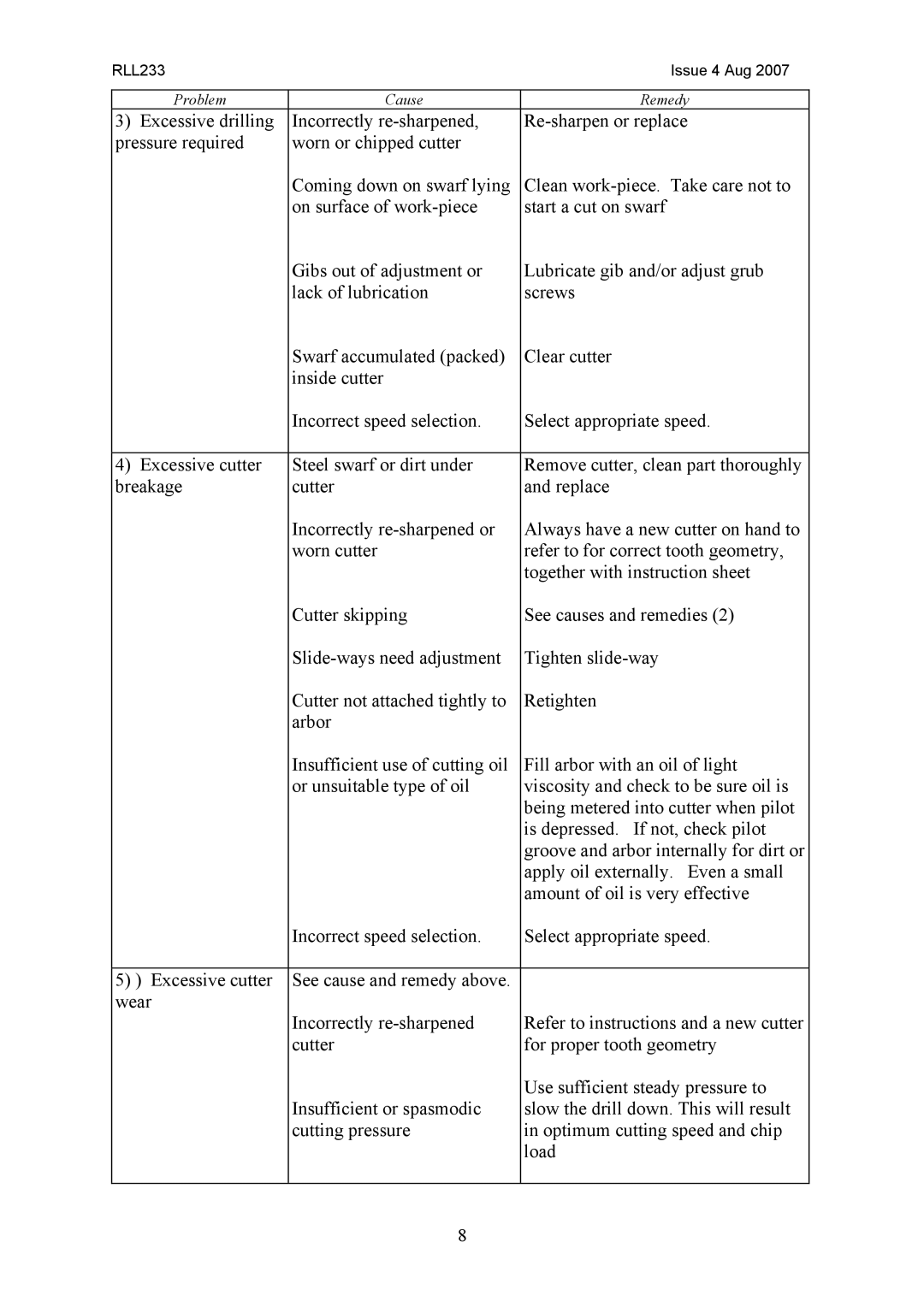

Problem | Cause | Remedy |

3) Excessive drilling | Incorrectly | |

pressure required | worn or chipped cutter |

|

| Coming down on swarf lying | Clean |

| on surface of | start a cut on swarf |

| Gibs out of adjustment or | Lubricate gib and/or adjust grub |

| lack of lubrication | screws |

| Swarf accumulated (packed) | Clear cutter |

| inside cutter |

|

| Incorrect speed selection. | Select appropriate speed. |

|

|

|

4) Excessive cutter | Steel swarf or dirt under | Remove cutter, clean part thoroughly |

breakage | cutter | and replace |

| Incorrectly | Always have a new cutter on hand to |

| worn cutter | refer to for correct tooth geometry, |

|

| together with instruction sheet |

| Cutter skipping | See causes and remedies (2) |

| Tighten | |

| Cutter not attached tightly to | Retighten |

| arbor |

|

| Insufficient use of cutting oil | Fill arbor with an oil of light |

| or unsuitable type of oil | viscosity and check to be sure oil is |

|

| being metered into cutter when pilot |

|

| is depressed. If not, check pilot |

|

| groove and arbor internally for dirt or |

|

| apply oil externally. Even a small |

|

| amount of oil is very effective |

| Incorrect speed selection. | Select appropriate speed. |

|

|

|

5) ) Excessive cutter | See cause and remedy above. |

|

wear |

|

|

| Incorrectly | Refer to instructions and a new cutter |

| cutter | for proper tooth geometry |

|

| Use sufficient steady pressure to |

| Insufficient or spasmodic | slow the drill down. This will result |

| cutting pressure | in optimum cutting speed and chip |

|

| load |

|

|

|

8