IMI-682 specifications

Cooper Lighting's IMI-682 is a standout choice for commercial and industrial lighting solutions, representing a meld of advanced technology and practical design. With its remarkable blend of efficiency and style, the IMI-682 is engineered to deliver exceptional performance while enhancing the aesthetics of any space.One of the key features of the IMI-682 is its energy-efficient LED technology. This integration not only reduces energy consumption but also extends the lifespan of the luminaire, ensuring long-term savings on maintenance and replacement costs. The IMI-682 provides an impressive lumen output, ensuring bright, uniform lighting that is ideal for various applications, including warehouses, retail spaces, and manufacturing facilities.

The design of the IMI-682 focuses on versatility. It is available in multiple configurations to suit different lighting needs, including adjustable beam angles and various color temperatures, allowing for tailored solutions in diverse environments. This flexibility makes it an excellent option for both new constructions and retrofitting existing lighting systems.

Another standout characteristic of the IMI-682 is its robust construction. Built with high-quality materials, this lighting fixture is designed to withstand the rigors of industrial settings, offering durability and reliability. Additionally, the fixture features an IP65 rating, making it suitable for both indoor and outdoor installations while providing protection against dust and water ingress.

The IMI-682 also incorporates advanced control technologies, allowing for easy integration with building management systems and smart lighting solutions. Its ability to work with dimmers and occupancy sensors further enhances energy savings and operational efficiency, making it an ideal choice for modern facilities aiming to improve their sustainability practices.

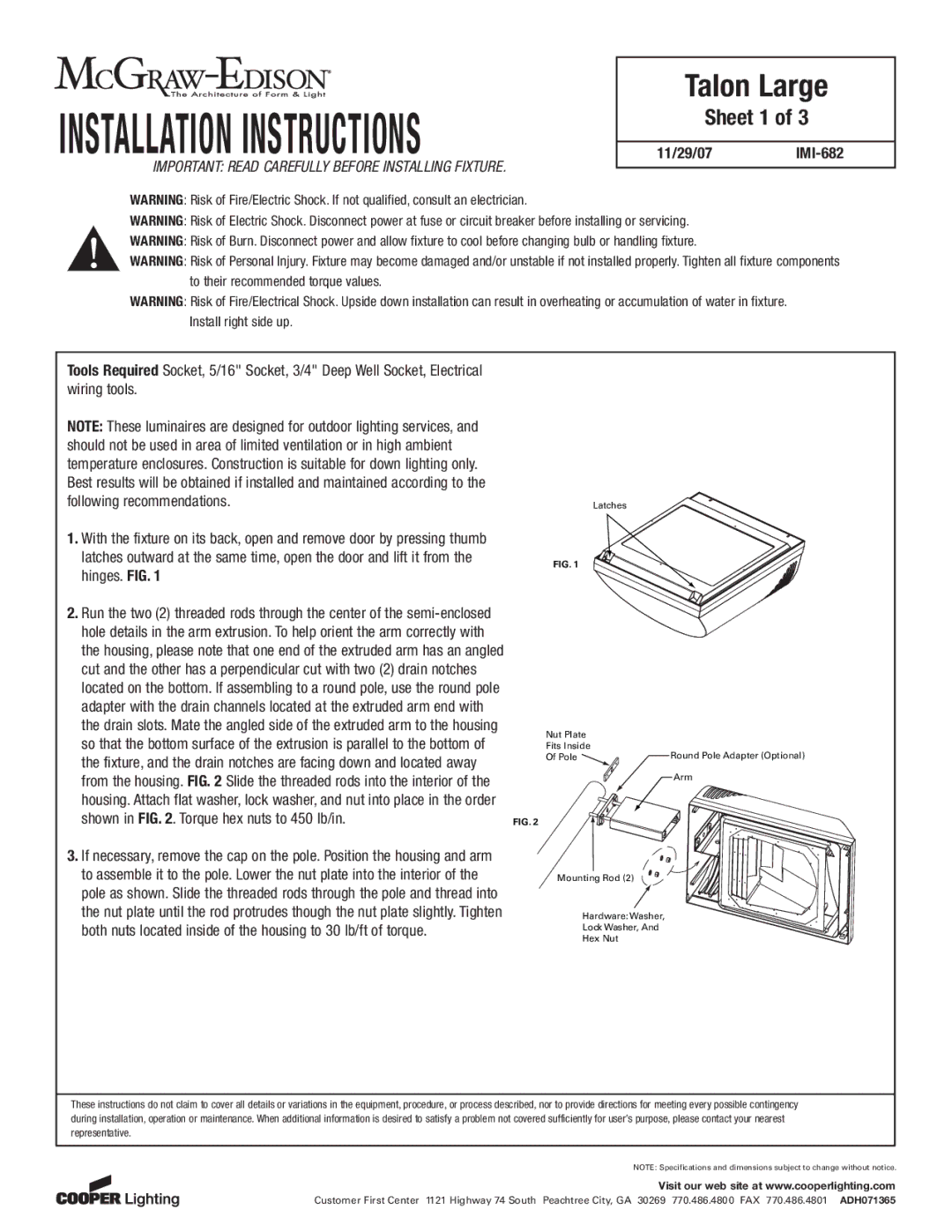

In terms of installation, the IMI-682 is designed for ease of use. Its lightweight nature and user-friendly mounting options simplify the installation process, reducing downtime and disruption in busy environments.

Overall, the Cooper Lighting IMI-682 is an innovative fixture that combines advanced LED technology, robust design, and operational flexibility, making it a top-tier choice for those seeking high-performance lighting solutions. With its blend of efficiency, durability, and adaptability, it stands out as a reliable option for a wide range of commercial and industrial applications.