CLEANING THE ICE BIN

1.Prepare a mild detergent soap solution in 100)F potable water.

2.Using a nylon (not wire) bristle brush, clean the cold plate and the interior of the ice bin with the soap solu- tion.

3.Rinse the cold plate and interior bin surfaces with clean potable water.

4.Using a mechanical spray bottle, prepare a sanitizing solution according to the manufacturer’s directions and spray the entire interior bin surfaces. Allow to air dry.

CONNECTING PRODUCT TO THE DISPENSER

Note: All inlet connections are clearly marked with a label adjacent to the inlet connections.

Note: Always leak check all connections.

Note: A plumbing diagram when supplied with the unit, can be found in the dispensing tower.

PREPARING FOR OPERATION

On Units Without Electrically Operated Valves, Skip Steps 1 & 2 Below

1.Plug transformer into electrical outlet. The 24V supply must be connected in the dispensing tower.

2.Turn the

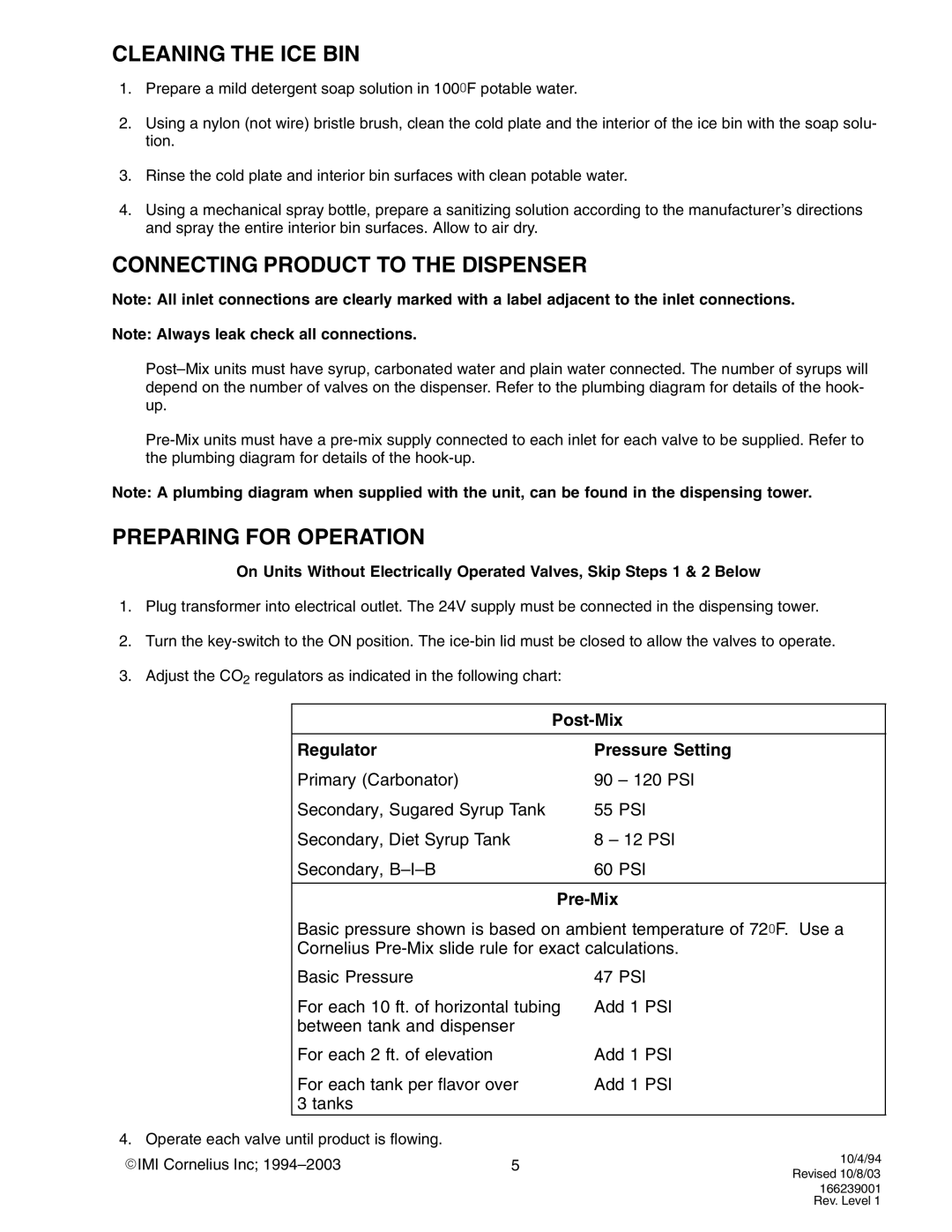

3.Adjust the CO2 regulators as indicated in the following chart:

|

| |||

|

|

|

| |

| Regulator |

| Pressure Setting | |

| Primary (Carbonator) |

| 90 – 120 PSI | |

| Secondary, Sugared Syrup Tank | 55 PSI | ||

| Secondary, Diet Syrup Tank |

| 8 – 12 PSI | |

| Secondary, |

| 60 PSI | |

|

|

| ||

|

| |||

| Basic pressure shown is based on ambient temperature of 72)F. Use a | |||

| Cornelius | |||

| Basic Pressure |

| 47 PSI | |

| For each 10 ft. of horizontal tubing | Add 1 PSI | ||

| between tank and dispenser |

| ||

| For each 2 ft. of elevation |

| Add 1 PSI | |

| For each tank per flavor over | Add 1 PSI | ||

| 3 tanks |

|

| |

4. Operate each valve until product is flowing. |

|

| ||

EIMI Cornelius Inc; | 5 | 10/4/94 | ||

Revised 10/8/03 | ||||

|

|

| ||

166239001 Rev. Level 1