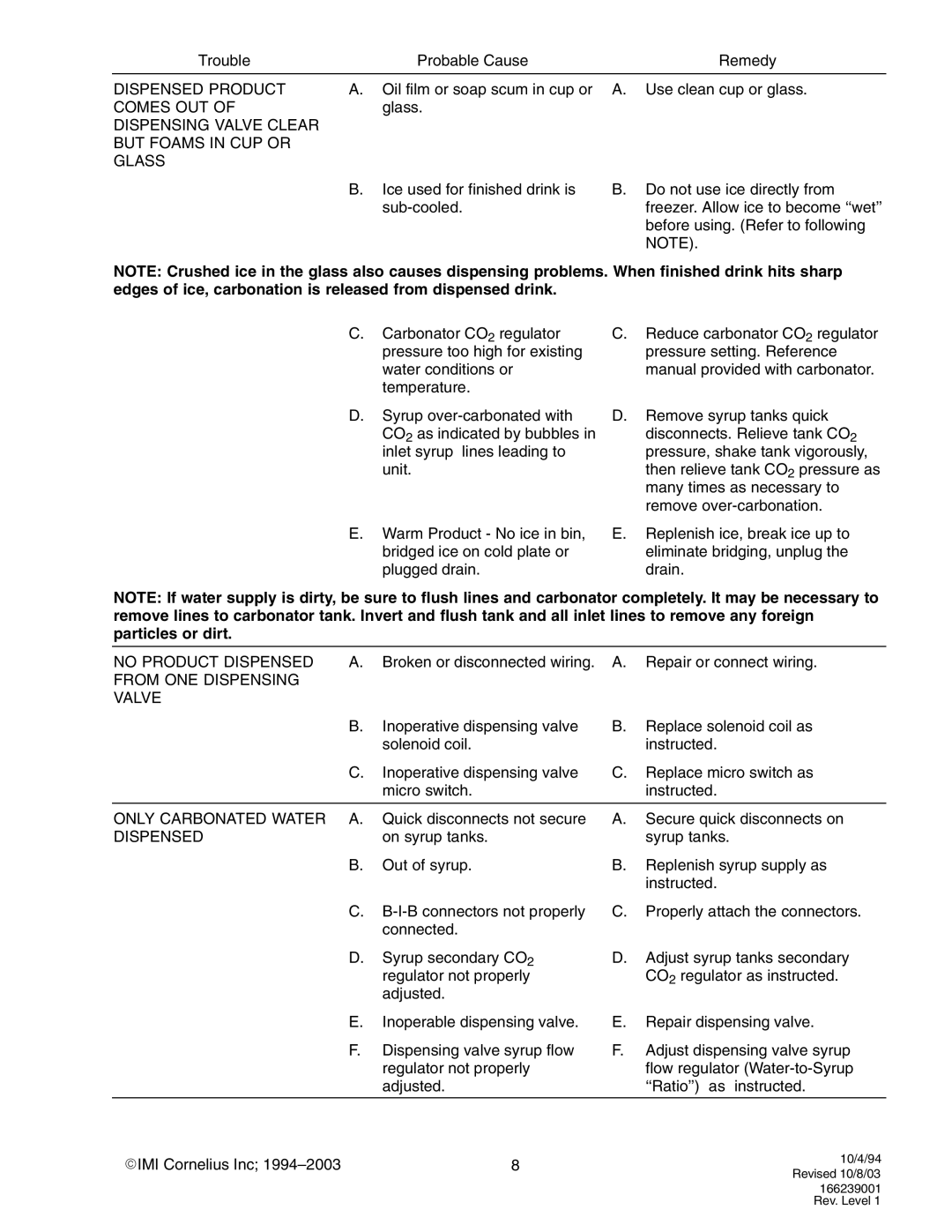

Trouble | Probable Cause | Remedy |

DISPENSED PRODUCT | A. Oil film or soap scum in cup or | A. Use clean cup or glass. |

COMES OUT OF | glass. |

|

DISPENSING VALVE CLEAR |

|

|

BUT FOAMS IN CUP OR |

|

|

GLASS |

|

|

| B. Ice used for finished drink is | B. Do not use ice directly from |

| freezer. Allow ice to become ‘‘wet’’ | |

|

| before using. (Refer to following |

|

| NOTE). |

NOTE: Crushed ice in the glass also causes dispensing problems. When finished drink hits sharp edges of ice, carbonation is released from dispensed drink.

C.Carbonator CO2 regulator pressure too high for existing water conditions or temperature.

C.Reduce carbonator CO2 regulator pressure setting. Reference manual provided with carbonator.

D.Syrup

CO2 as indicated by bubbles in inlet syrup lines leading to unit.

D.Remove syrup tanks quick

disconnects. Relieve tank CO2 pressure, shake tank vigorously,

then relieve tank CO2 pressure as many times as necessary to remove

E.Warm Product - No ice in bin, bridged ice on cold plate or plugged drain.

E.Replenish ice, break ice up to eliminate bridging, unplug the drain.

NOTE: If water supply is dirty, be sure to flush lines and carbonator completely. It may be necessary to remove lines to carbonator tank. Invert and flush tank and all inlet lines to remove any foreign particles or dirt.

NO PRODUCT DISPENSED | A. | Broken or disconnected wiring. | A. | Repair or connect wiring. |

FROM ONE DISPENSING |

|

|

|

|

VALVE |

|

|

|

|

| B. | Inoperative dispensing valve | B. Replace solenoid coil as | |

|

| solenoid coil. |

| instructed. |

| C. | Inoperative dispensing valve | C. Replace micro switch as | |

|

| micro switch. |

| instructed. |

|

|

|

| |

ONLY CARBONATED WATER | A. | Quick disconnects not secure | A. Secure quick disconnects on | |

DISPENSED |

| on syrup tanks. |

| syrup tanks. |

| B. | Out of syrup. | B. Replenish syrup supply as | |

|

|

|

| instructed. |

| C. | C. | Properly attach the connectors. | |

|

| connected. |

|

|

D.Syrup secondary CO2 regulator not properly adjusted.

E.Inoperable dispensing valve.

F.Dispensing valve syrup flow regulator not properly adjusted.

D.Adjust syrup tanks secondary CO2 regulator as instructed.

E.Repair dispensing valve.

F.Adjust dispensing valve syrup flow regulator

EIMI Cornelius Inc; | 8 | 10/4/94 | |

Revised 10/8/03 | |||

|

|

166239001 Rev. Level 1