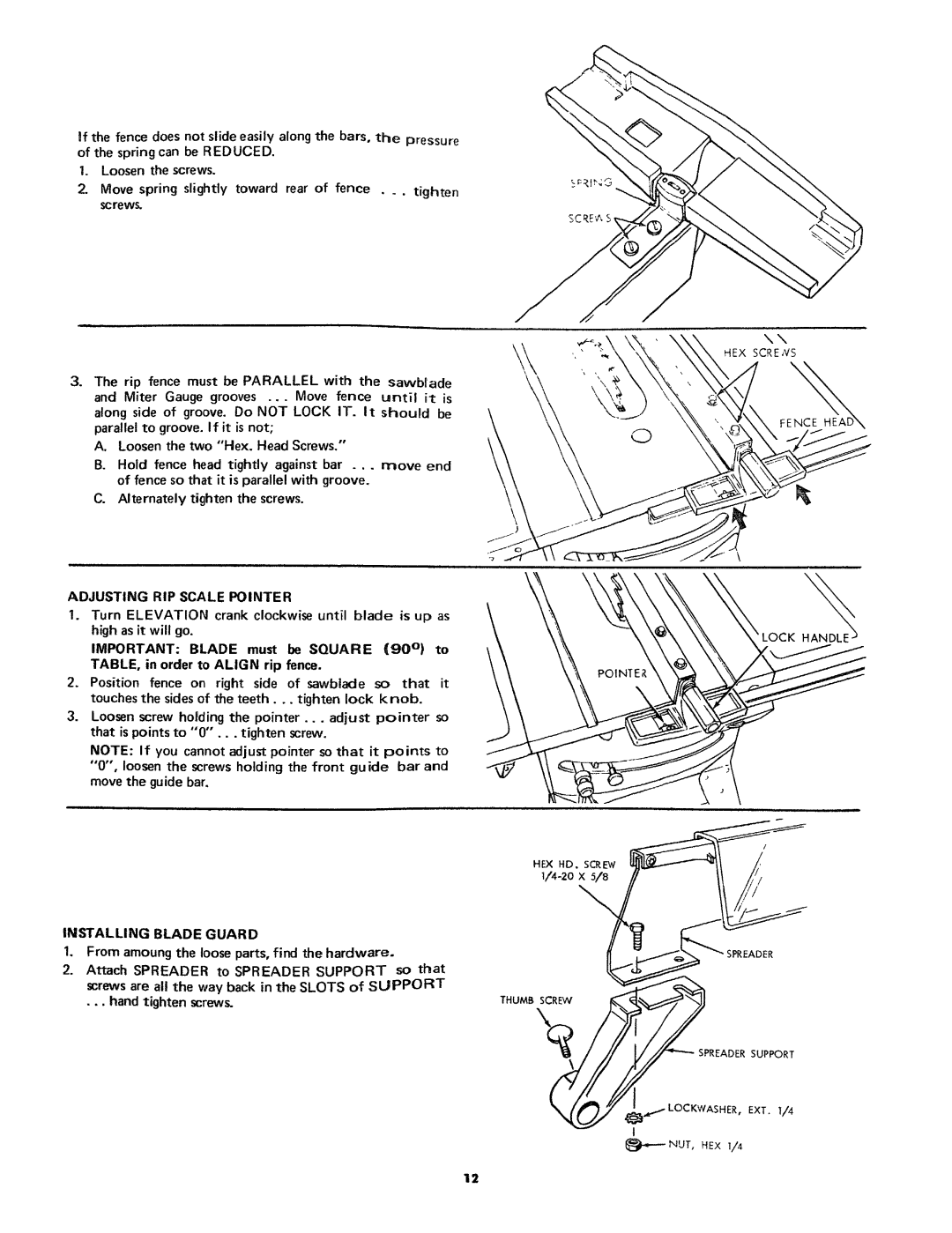

If the fence does not slide easily along the bars, the pressure of the spring can be REDUCED.

1.Loosen the screws.

2.Move spring slightly toward rear of fence . . . tighten screw_

3.The rip fence must be PARALLEL with the sawblade

and Miter Gauge grooves ... Move fence until it is

along side of groove. Do NOT LOCK IT. It should be parallel to groove. If it is not;

A.Loosen the two "Hex. Head Screws."

B.Hold fence head tightly against bar ... move end of fence so that it is parallel with groove.

C.Alternately tighten the screws.

ADJUSTING RIP SCALE POINTER

I. Turn ELEVATION crank clockwise until blade is up as high as it will go.

IMPORTANT: BLADE must be SQUARE {90 °) to

TABLE, in order to ALIGN rip fence.

2. Position fence on right side of sawblade so that it

touches the sides of the teeth.., tighten lock knob.

3. Loosen screw | holding | the pointer.., | adjust | pointer | so | |

that is points | to "0"... | tighten | screw. |

|

|

|

NOTE: If you cannot adjust pointer so that it points to "0", loosen the screws holding the front guide bar and move the guide bar.

INSTALLING BLADE GUARD

1, From amoung the loose parts, find the hardware.

2.Attach SPREADER to SPREADER SUPPORT so that screws are all the way back in the SLOTS of SUPPORT

... hand tighten screws.

\\

HEX SCRE_VS

\

\

\

'LOCK

HEX HD. SO_.EW

\

SPREADER

THUMB SCREW I_

'q//READER SUPPORT

_I._e.._LOCKWASHER, EXT. I/4

NUT, HEX I/4

12