the supply circuit) or when the supply circuit is

extremely long. Always check connections, load and

supply circuit when the motor fails to perform

satisfactorily. Check wire sizes and lengths with the table in the next paragraph. Replace or repair damaged or worn cord immediately.

CONNECTING TO POWER SOURCE OUTLET

This saw must be grounded while in use to protect the operator from electrical shock.

If power cord is worn or cut, or damaged in any way, have it replaced immediately.

CAUTION: | This | saw | is wired | for operation | on 240 | volts |

only. Connect to | a 15 | ampere | branch circuit | protected | by a | |

15 ampere time delay or circuit saver fuse or circuit breaker,

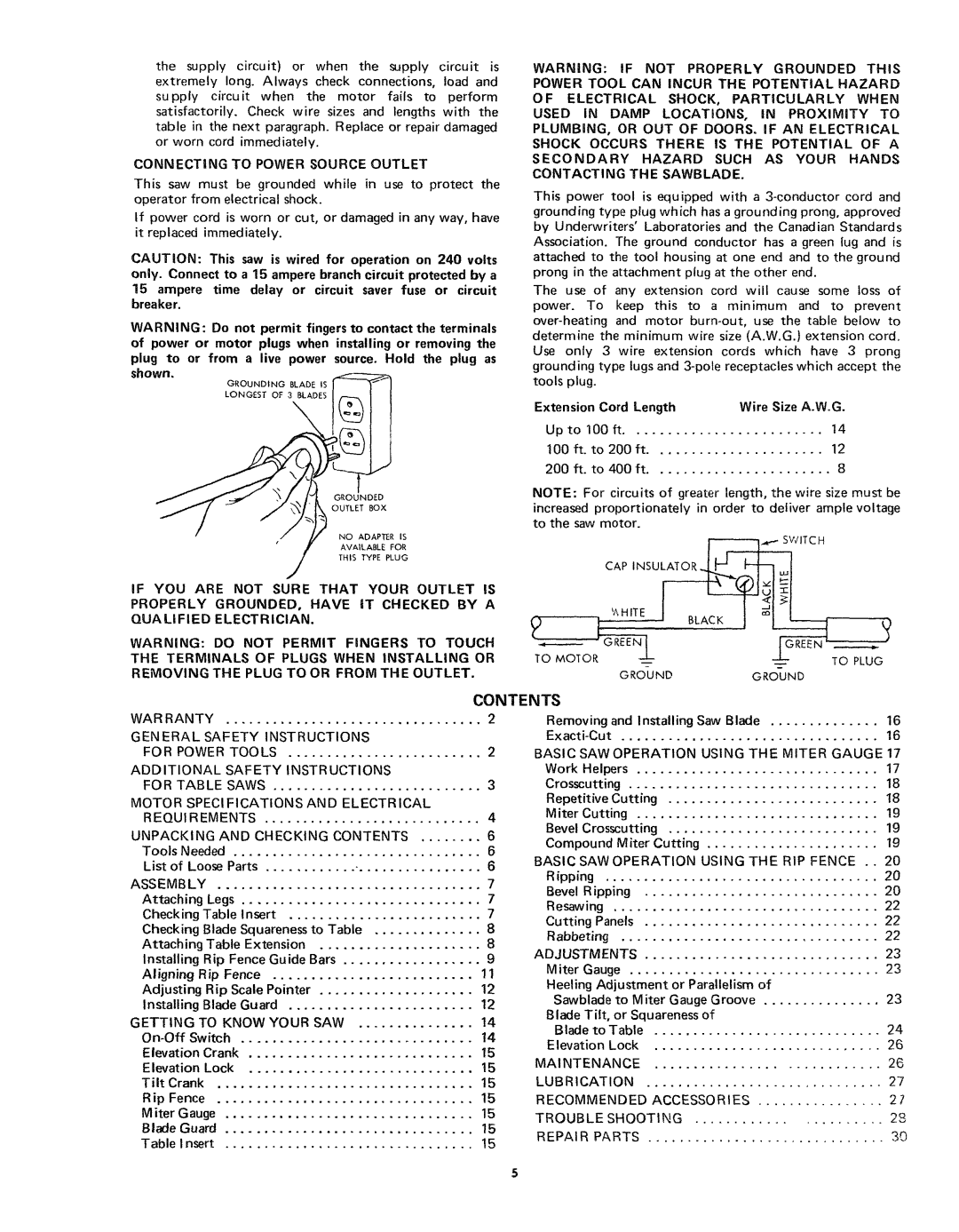

WARNING: Do not permit fingers to contact the terminals

of power or motor plugs when installing or removing the plug to or from a live power source. Hold the plug as shown,

GROUNDING BLADE IS

LONGEST OF 3 BLADES

GROUNDED

OUTLET BOX

NO ADAPTER IS

AVAILABLE FOR

THIS TYPE PLUG

WARNING: IF NOT PROPERLY GROUNDED THIS POWER TOOL CAN INCUR THE POTENTIAL HAZARD

OF ELECTRICAL SHOCK, PARTICULARLY WHEN

USED IN DAMP LOCATIONS, IN PROXIMITY TO PLUMBING, OR OUT OF DOORS. IF AN ELECTRICAL SHOCK OCCURS THERE IS THE POTENTIAL OF A

SECONDARY HAZARD SUCH AS YOUR HANDS CONTACTING THE SAWBLADE.

This power tool is equipped with a

by Underwriters' Laboratories and the Canadian Standards

Association. The ground conductor has a green lug and is attached to the tool housing at one end and to the ground

prong in the attachment plug at the other end.

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent

determine the minimum wire size (A.W.G.) extension cord.

Use only 3 wire extension cords which have 3 prong grounding type lugs and

Extension | Cord | Length | Wire Size A.W.G. | ||

Up | to | 100 | ft | 14 | |

100 | ft. | to | 200ft | ...................... | 12 |

200 | ft. | to | 400 | ft | 8 |

NOTE: For circuits of greater length, the wire size must be

increased proportionately in order to deliver ample voltage to the saw motor.

_- SWITCH

IF YOU ARE NOT SURE THAT YOUR OUTLET IS

PROPERLY GROUNDED, HAVE IT CHECKED BY A

QUALIFIED ELECTRICIAN.

WARNING: DO NOT | PERMIT FINGERS TO TOUCH |

| |

THE TERMINALS OF | PLUGS WHEN INSTALLING | OR |

|

REMOVING THE PLUG TO OR FROM THE OUTLET. | GROUND | GROUND | |

CONTENTS

WAR RANTY | ................................. |

|

|

| 2 | ||||

GENERAL | SAFETY | INSTRUCTIONS |

| ||||||

FOR | POWER | TOOLS |

| 2 | |||||

ADDITIONAL |

| SAFETY INSTRUCTIONS |

| ||||||

FOR | TABLE | SAWS | ........................... |

| 3 | ||||

MOTOR | SPECIFICATIONS | AND | ELECTRICAL |

| |||||

REQUIREMENTS |

| ............................ |

| 4 | |||||

UNPACKING | AND CHECKING | CONTENTS | 6 | ||||||

Tools |

| Needed | ................................ |

|

|

| 6 | ||

List | of | Loose | Parts | ............ |

| 6 | |||

ASSEMBLY | .................................. |

|

|

|

| 7 | |||

Attaching | Legs | ............................... |

|

| 7 | ||||

Checking | Table | Insert |

| 7 | |||||

Checking | Blade | Squareness | to Table | 8 | |||||

Attaching | Table | Extension | ..................... | 8 | |||||

Installing | Rip | Fence | Guide | Bars | .................. | 9 | |||

Aligning |

| Rip | Fence | .......................... |

| 11 | |||

Adjusting | Rip | Scale | Pointer | .................... | 12 | ||||

Installing | Blade | Guard |

| 12 | |||||

GETTING |

| TO | KNOW | YOUR | SAW | !4 | |||

Switch |

| .............................. |

|

| 14 | ||||

Elevation | Crank | ............................. |

|

| 15 | ||||

Elevation | Lock | ............................. |

|

| 15 | ||||

Tilt | Crank | ................................. |

|

|

|

| 15 | ||

Rip | Fence |

|

|

|

| 15 | |||

Miter | Gauge | ................................ |

|

|

| 15 | |||

Blade |

| Guard | ................................ |

|

|

| 15 | ||

Table |

| insert | ................................ |

|

|

| !5 | ||

Removing | and | Installing | Saw Blade | 16 | ||

................................. |

| 16 | ||||

BASIC | SAW OPERATION | USING THE MITER GAUGE 17 | ||||

Work | Helpers | ............................... | 17 | |||

Crosscutting | ................................ |

| 18 | |||

Repetitive | Cutting | 18 | ||||

Miter | Cutting | ............................... | 19 | |||

Bevel | Crosscutting | 19 | ||||

Compound | Miter Cutting | ...................... | 19 | |||

BASIC | SAW OPERATION | USING THE RIP FENCE .. 20 | ||||

Ripping |

| ................................... |

| 20 | ||

Bevel | R ipping | .............................. | 20 | |||

Resawing | .................................. |

| 22 | |||

Cutting | Panels | .............................. | 22 | |||

Rabbeting | ................................. |

| 22 | |||

ADJUSTMENTS | .............................. | 23 | ||||

Miter | Gauge |

| 23 | |||

Heeling Adjustment or Parallelism of |

| |||||

Sawblade | to | Miter Gauge Groove | 23 | |||

Blade Tilt, or Squareness of |

| |||||

Blade | to | Table | 24 | |||

Elevation |

| Lock | ............................. | 26 | ||

MAINTENANCE | ............................ | 26 | ||||

LUBRICATION | .............................. | 27 | ||||

RECOMMENDED | ACCESSORIES | 2 7 | ||||

TROUBLE |

| SHOOTING | 2S | |||

REPAIR |

| PARTS | .............................. | 30 | ||