SPECnFIC SAFETY NSTRUCTMONS FOR THE DR LL PRESS

For your own safety, do not try to use your drill press

or plug it in until it is completely assembled and installed according tO the instructions, and until you have read and understood this instruction manual:

1.YOUR DRILL PRESS MUST BE BOLTED securely to a workbench. In addition, ff there is any tendency

for your drill press to move during certain operations, bolt the workbench to the floor.

2.THIS DRILL PRESS is intended for use in dry conditions, indoor use only.

. WEAR EYE PROTECTION. USE face or dust mask along with safety goggles if drilling operation is dusty. USE ear protectors, especially during extended periods of operation.

4.DO NOT wear gloves, neckties, or loose clothing. :

5.DO NOT try to drill material too small to be securely held.

6.ALWAYS keep hands out of the path of a drill bit. Avoid awkward hand positions where a sudden slip could cause your hand to move into the drill bit.

I4. SECURE WORK. Use clamps or a vise to hold the work when practical. It'ssafer than using your hand and it Frees both hands to operate tool.

15.WHEN using a drill press vise, always fasten to the table.

16.MAKE SURE all clamps and locks are firmly tightened before drilling.

17.SECURELY LOCK THE HEAD and table support to the column, and the table to the table support before operating the drill press.

18.NEVER turn your drill press on before clearing the table of all objects (-tools, scraps of wood, etc.)

I9. BEFORE STARTING the Operation, jog'the motor switch to make sure the drill bit does not wobble or vibrate.

20.LETTHE SPINDLE REACH FULL SPEED before starting to drill. If your drill press makes an unfamiliar noise or if it vibrates excessively, stop immediately, turn the drill press off and unplug. Do not restart until the problem is corrected

::}i

21, DO NOT perform layout assembly or set up work on q the table while the drill press is in operation.

22. USE RECOMMENDED SPEED for drill accessory and |

workpiece material. SEE INSTRUCTIONS that come |

with the accessory. |

GROUNDING INSTRUCTIONS

INTHE EVENT OF A MALFUNCTION OR BREAKDOWN, grounding provides a path of least resistance for electric current and reduces the risk of electric shock. This tool is equipped with an electric cord that has an equipment grounding conductor and a grounding plug. The plug MUST be plugged into a matching receptacle that is

properly installed and grounded in accordance with ALL local codes and ordinances.

DO NOT MODIFYTHE PLUG PROVIDED. tf it wilt no[ fit [he receptacle, have the proper receptacle installed by a qualified electrician.

IMPROPER CONNECTION of the equipment grounding conductor can result in risk of electric shock. The

conductor with the green insulation (with or without yeltow stripes) is the equipment grounding conductor. If repair or replacement of the electric cord or plug is necessary,

DO NOT connect the equipment grounding conductor to a live terminal.

CHECK with a qualified electrician or service personnel if you do not completely understand the grounding instructions, or if you are not sure the tool is properly grounded.

USE ONLY 3oWIRE EXTENSION CORDS THAT HAVE 3-PRONGGROUNDING PLUGS AND 3opOLE

RECEPTACLES THAT ACCEPT THE TOOL'S PLUG. REPAIR OR REPLACE DAMAGED OR WOF_?,_CORD IMMEDIATELY.

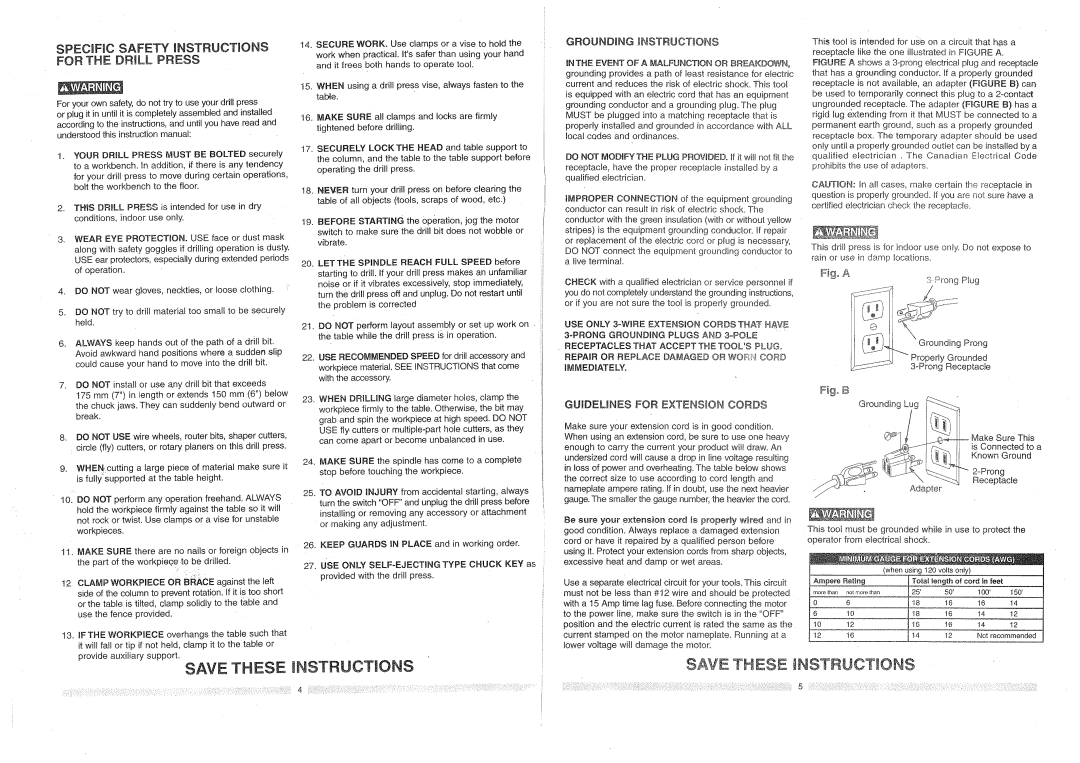

This tool is intended for use on a circuit that has a receptacle iike the one illustrated in FIGURE A. FIGURE A shows a 3-prong electrical plug and receptacle that has a grounding conductor. If a properly grounded receptacle is not available, an adapter (F_GURE B) can. be used to temporarily connect this plug to a 2-contact

ungrounded receptacle. The adapter (RGURE B) has a rigid lug extending from it that MUST be connected to a

permanent earth ground, such as a properly grounded receptacle box. The temporary adapter should be used only until a properly grounded outle_ can be installed by a qualified electrician . The Canadian E!ectrical Code prohibits the use of adapters.

CAUTION: In all cases, make certain the receptacle in question is property grounded. If you are not sure have a codified electrician check the receptacle.

This drill press is for indoor use only. Do not expose to rain or use in damp locations.

Fig° A

3-Prong Plug

(

Grounding Prong

Properly Grounded

3-Prong Receptacle

. DO NOT install or use any drill bit that exceeds

!75 mm (7") in length or extends 150 mm (6") below the chuck jaws. They can suddenly bend outward or break.

8.DO NOT USE wire wheels, router bits, shaper cutters, circle (fly) cutters, or rotary planers on this drill press.

9.WHEN;cutting a large piece of material make sure it is fully'supported at the table height.

10.DO NOT perform any operation freehand. ALWAYS hold the workpiece firmly against the table so it will not rock or twist. Use clamps or a vise for unstable workpieces.

11.MAKE SURE there are no nails or foreign objects in the part of the workpiec.e to be drilled.

t2 CLAMP WORK:PIECE OR BRACE against the left side of the column to prevent rotation. If it is too short or the table is tilted, clamp solidly to the table and use the fence provided,

23. WHEN DRILLING large diameter holes, clamp the |

workpiece firmly to the table. Otherwise, the bit may |

grab and spin the workpiece at high speed. DO NOT |

USE fly cutters or multiple-part hole cutters, as they |

can come apart or become unbalanced in use. |

24. MAKE SURE the spindle has come to a complete |

stop before touching the workpiece. |

25. TO AVOID INJURY from accidental starting, always |

turn the switch "OFF" and unplug the drill press before |

installing or removing any accessory or attachment |

or making any adjustment. |

KEEP GUARDS lN PLACE and in working order.

26.

27.USE ONLY SELF-EJECTING TYPE CHUCK KEY as provided with the drill press.

GU_DEUNES FOR EXTENSION CORDS

Make sure your extension cord is in good condition. When using an extension cord, be sure to use one heaw enough to carry the current your product wil! draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. The table below shows the correct size to use according to cord length and nameplate ampere rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the cord.

Be sure your extension cord _s property wired and in good condition. Always replace a damaged extension cord or have it repaired by a qualified person before using it. Protect your extension cords from sharp objects, excessive heat and damp or wet areas.

Use a separate electrical circuit for your tools. This circuit must not be less than #t2 wire and should be protected with a 15 Amp time tag fuse. Before connecting the motor to the power line, make sure the switch is in the "OFF" position and the electric current is rated the same as the

F_9. B

Grounding Lug

is Connected to a Known Ground

I Make Sure This 2-Prong Receptacle

This toof must be grounded while in use to protect the operator from electrical shock.

| | (when | using 120 volts | only) | |

| Arc@ere | Rating | l Total | length | of | cord in feet | |

| more than | not mere then | [25' | 50' | 100' | t 50 ' |

| 0 | 6 |

| ! 18 | 16 | | 16 | 14 |

| | | |

| 6 | 10 | | | | | |

| 10 | 12 | 1618 | 16 | | 14 | 12 |