CHANGINGCOLLETINSERT

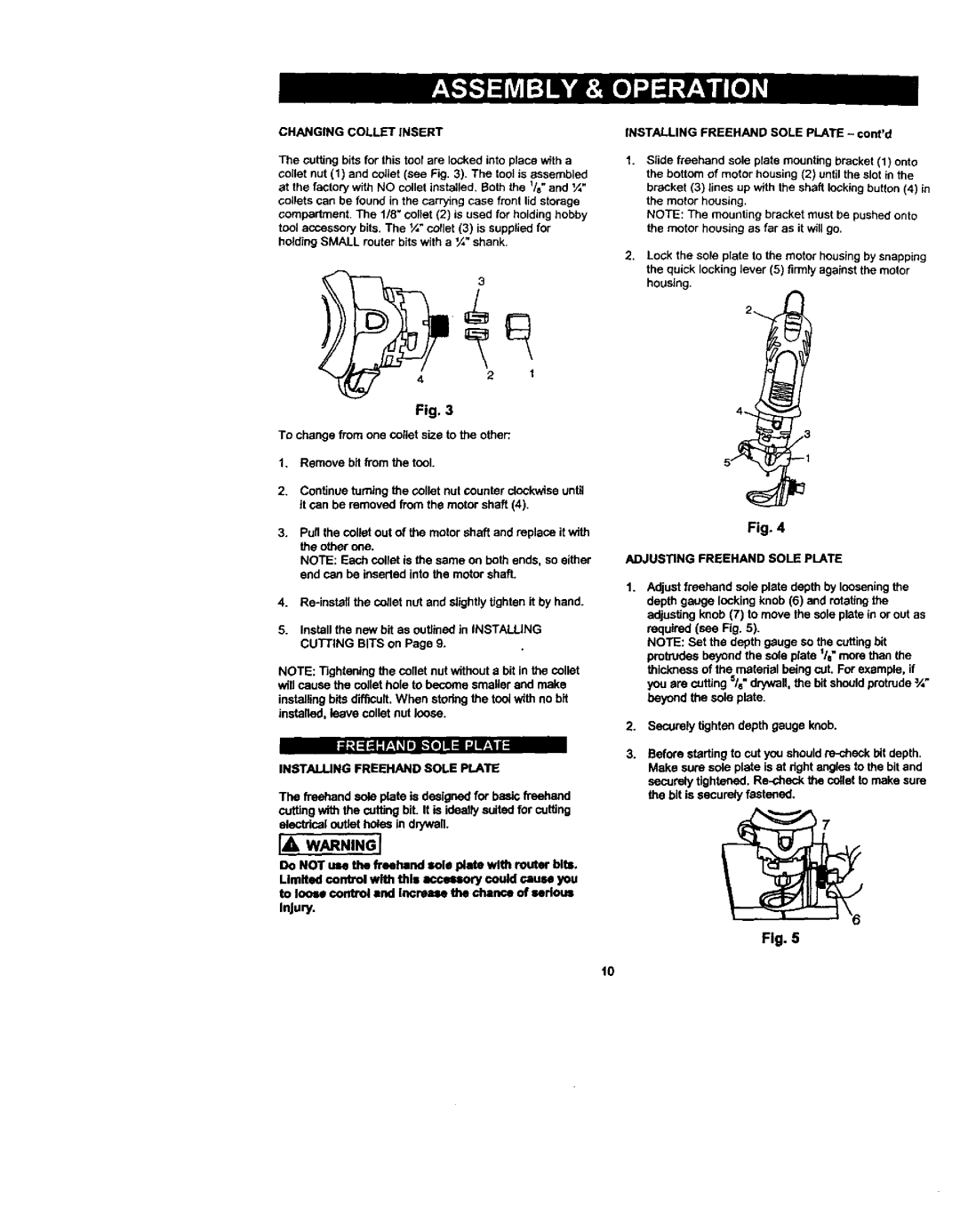

Thecutting bits for this tool are locked into place with a collar nut (1) and coJlet (see Fig. 3). The tool is assembled at the factory with NO coilet installed. Both the l/a" and ¼" coilets can be found in the carrying case front lid storage compartment. The 1/8" toilet (2) is used for holding hobby tool accessory bits. The ¼" coflet (3) is supplied for holding SMALL router bits with a %" shank.

Fig. 3

To change from one cotlet size to the other:.

1.Remove bit from the tool.

2.Continue turning the collet nut counter clockwise until it can be removed from the motor shaft (4).

3.Pull the co,el out of the motor shaft and replace itwith the other one.

NOTE: Each collet is the same on both ends, so either end can be inserted into the motor shaft,

4.

5.Install the new bit as outlined in INSTALLING CUTTING BITS on Page 9.

NOTE: Tightaning the oollet nut without a bit in the sallet will cause the collet hole to become smaller and make

installing bits difficult. When stodng the toot with no bit installed, leave collet nut loose.

j

INSTALLING FREEHAND SOLE PLATE

The freehand sole plate is designed for basic freehand cuffing with the cuffing bit. It is ideally suited for cuffing electrical outlet holes in dPJwall.

IA WARNING I

Do NOT use the freehand sole plate with router bits. Limited control with this accmmory could cause you to lOOSecontrol and Increasethe chance of serious

Injury,

INSTALLING FREEHAND SOLE PLATE - €ont'd

1.Slide freehand sole plate mounting bracket (1) onto the bottom of motor housing (2) until the slot in the

bracket (3) lines up with the shaft locking button (4) in the motor housing.

NOTE: The mounting bracket must be pushed onto the motor housing as far as it will go.

2.Lock the sole plate to the motor housing by snapping the quick locking lever (5) firmly against the motor housing.

2

4

3

5

Fig. 4

ADJUSTING FREEHAND SOLE PLATE

1.Adjust freehand sole plate depth by loosening the depth gauge locking knob (6) and rotating the adjusting knob (7) to move the sole plate in or out as

required (see Rg. 5).

NOTE: Set the depth gauge so the cutting bit protrudes beyond the sole plate 1/0" more than the thickness of the matadal being cut. For example, if you are cutting s/6"drywall, the bit should protrude ¾" beyond the sole plate.

2.Securely tighten depth gauge knob.

3.Before starting to cut you should

securely tightened.

Fig. 5

lO